Digital Pixel RGBW (3000K) COB Strip 24V IP20 784 LEDs/m WS2814 10mm wide

From £23.85Unit price /UnavailableDigital Pixel RGB COB Strip 24V IP20 720 LEDs/m WS2811 10mm wide

From £17.85Unit price /UnavailableAddressable Digital Pixel RGB COB Strip 24V IP68 Waterproof 720 LEDs/m WS2811

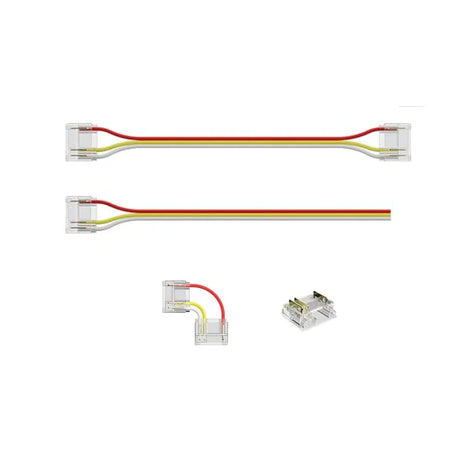

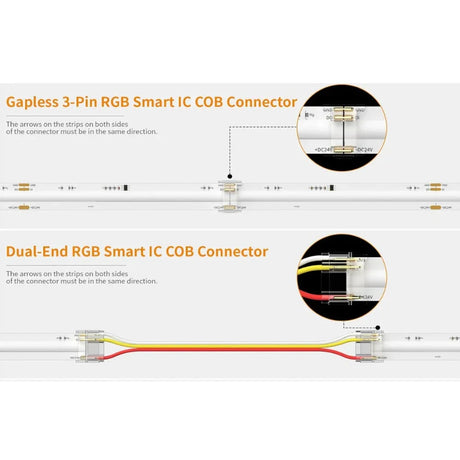

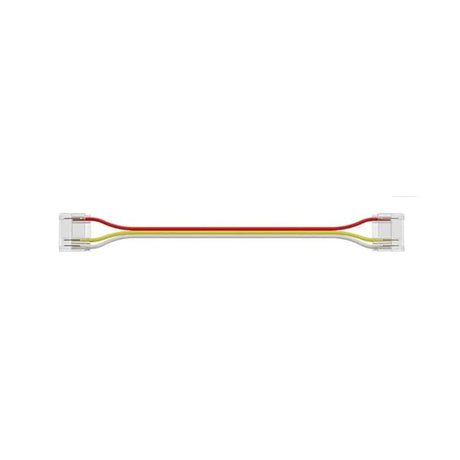

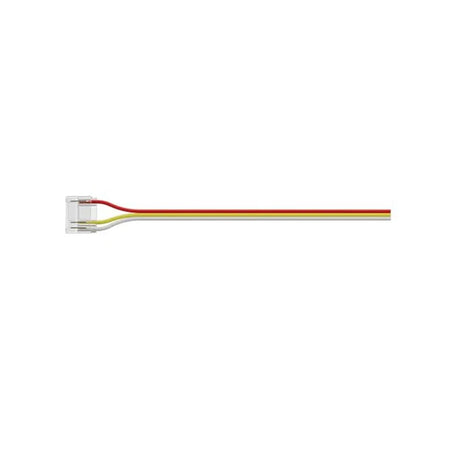

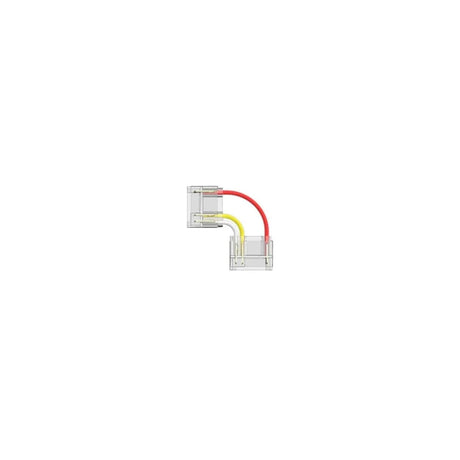

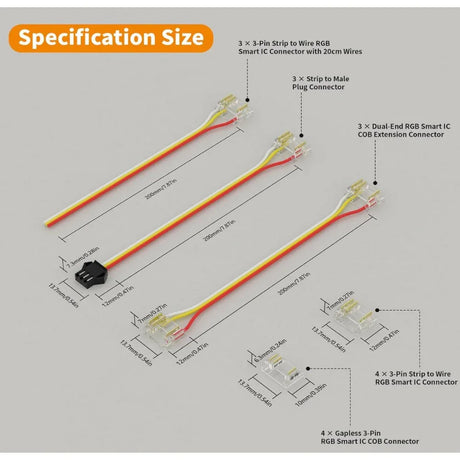

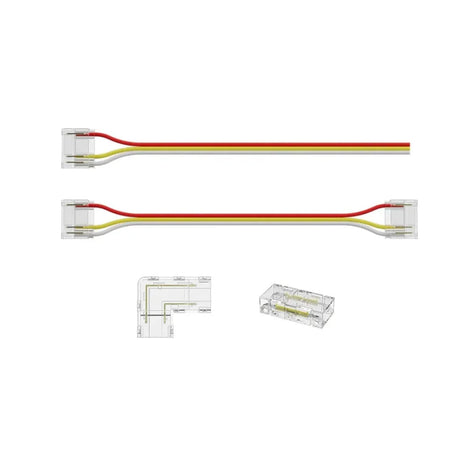

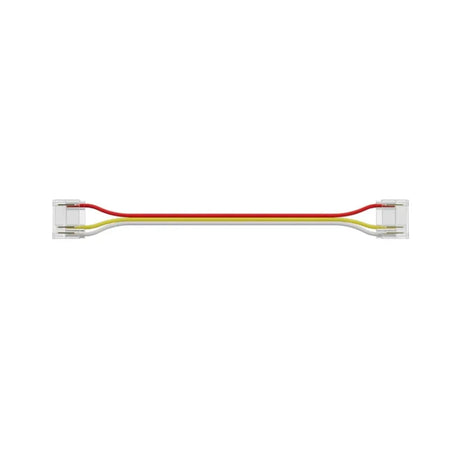

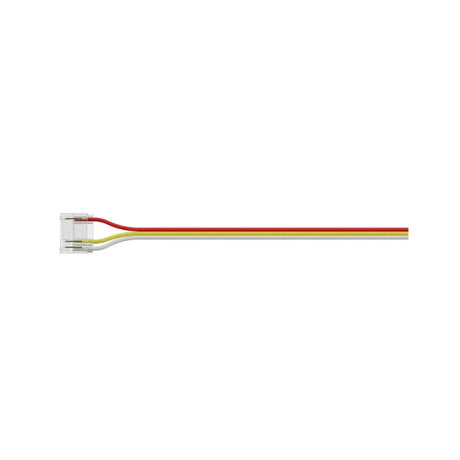

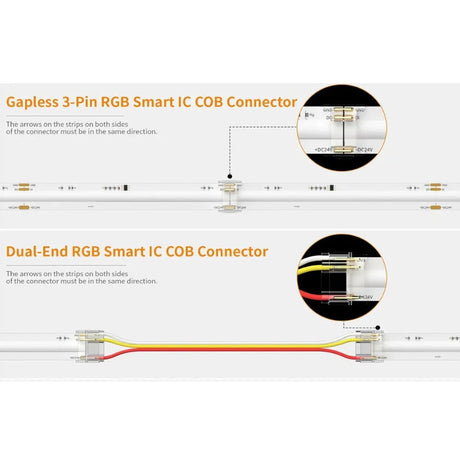

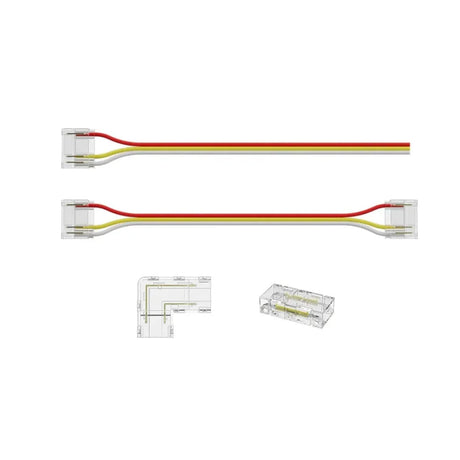

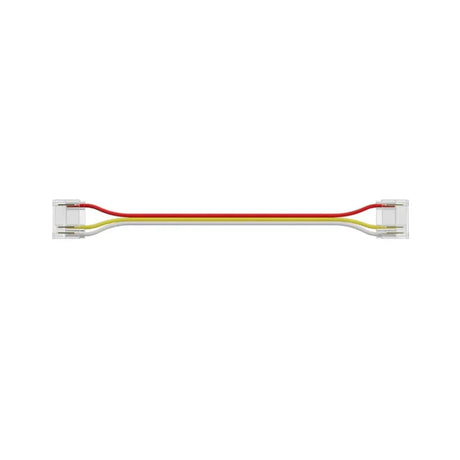

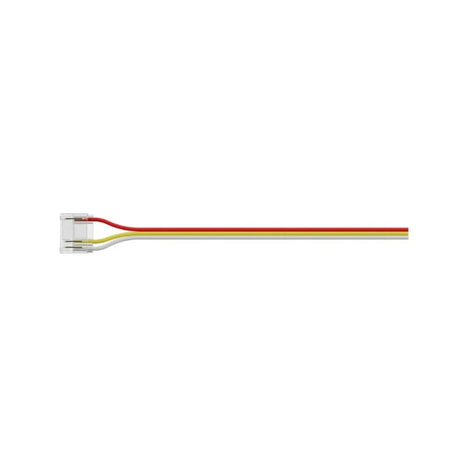

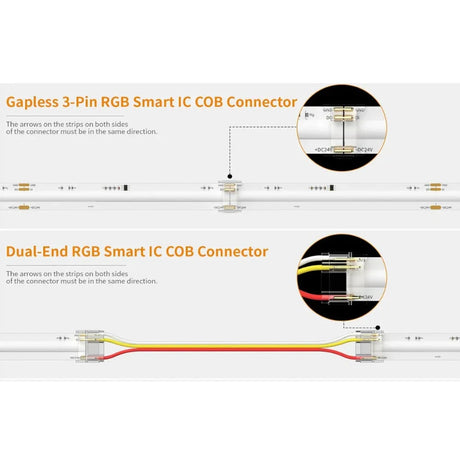

From £117.50Unit price /Unavailable12mm 3-Pin Connectors Kit for RGB IC SPI COB LED Strip Light IP20

From £5.95Unit price /Unavailable10mm 3-Pin Connectors Kit for RGB IC SPI COB LED Strip Light IP20

From £5.95Unit price /Unavailable8mm 3-Pin Connectors Kit for RGB IC SPI COB LED Strip Light IP20

From £5.95Unit price /UnavailableDigital Pixel RGB CCT COB Strip 24V IP20 840 LEDs/m WS2805 15mm Wide

From £25.52Unit price /Unavailable

Why do running water effects stutter on long runs, and how can data injection help?

Stuttering is often caused by voltage drop or signal degradation, which can be improved by adding power injection points or signal repeaters along the run.

What power supply size is required for a 5 m IP67 running water RGB strip at 15 W/m?

A 5 m strip at 15 W/m requires 75 W total, so a 24V power supply rated around 90–100 W is recommended for safe operation.

How do I mount waterproof running water strips for outdoor decking or perimeter lighting?

Use aluminum channels or mounting clips rated for outdoor use, ensure proper water runoff, and avoid trapping moisture beneath the strip.

Can running water strips be cut, and what spacing is needed between sections for seamless effects?

Strips can usually be cut at marked cut points, but maintaining consistent spacing and orientation between sections is critical to preserve smooth visual flow.

How do I connect a 24V running water strip to a power supply and remote for speed control?

The strip is powered by a 24V constant-voltage supply and connected to a compatible controller or inline driver that adjusts speed, direction, and effect via remote or app.

What controllers work with running water LED strips for flow, chase, or firework effects?

Compatible controllers include dedicated running-water controllers, SPI pixel controllers, or DMX decoders that support chase-style animation patterns.

How do I wire multiple running water strips in parallel?

Each strip should be connected directly to the power source in parallel to maintain consistent voltage and effect speed across all runs.

How do I size the power supply for 24V running water strips?

Calculate total wattage (W/m × total length), divide by 24V for current, and choose a power supply with at least 20–30% headroom for stable operation.

What are the installation steps for waterproof running water strips?

Installation typically involves surface preparation, secure mounting, sealed electrical connections, proper drainage orientation, and testing before final weatherproof sealing.

Compare running water strip types and control protocols

Running water strips may use simple built-in chaser ICs or fully addressable protocols (SPI/DMX), with addressable versions offering finer control over direction, speed, and effects.

Are running water strips compatible with app control or music sync for retail displays?

Many modern running water systems support app-based control or music sync when paired with compatible controllers designed for dynamic visual effects.

How do I troubleshoot a non-responsive running water strip?

Check power polarity, controller compatibility, signal direction, and connector integrity before testing with a known-good power source or controller.

How do I solder waterproof running water strips safely?

Solder only at designated pads, use heat-shrink and waterproof sealant, and fully reseal the joint to maintain the strip’s IP rating.

What is the best power injection interval for 24V running water strips?

Power is commonly injected every 5–10 metres depending on wattage and cable size to maintain consistent brightness and effect speed.

How do I calculate total wattage for multiple running water strips?

Add together the wattage of each strip run, then size the power supply to exceed the combined load with adequate safety margin.

Should running water strips be wired in parallel or series?

Parallel wiring is preferred to ensure uniform voltage and synchronized effects, while series wiring is generally avoided due to uneven performance.