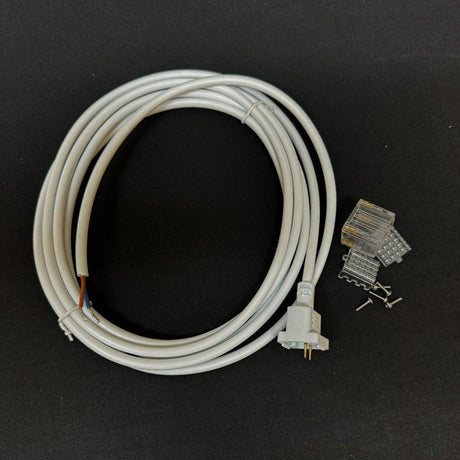

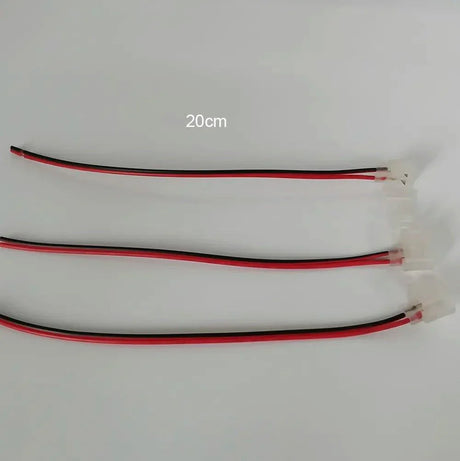

1 Metre DC 12V/24V RGB LED Strip 4 Pin Soldless Connector Cables 5050 3528

£5.72Unit price /Unavailable2 Metre DC 12V/24V RGB LED Strip 4 Pin Soldless Connector Cables 5050 3528

£6.85Unit price /Unavailable5 Metre DC 12V/24V RGB LED Strip 4 Pin Soldless Connector Cables 5050 3528

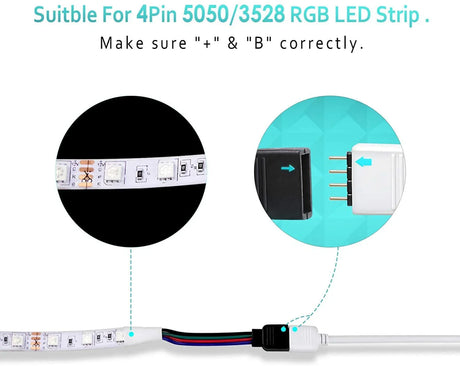

£12.72Unit price /Unavailable1 to 3 Ports Female/Male Connection Cable 4 Pin Splitter Cable

£6.25Unit price /Unavailable1 to 2 Ports Female/Male Connection Cable 4 Pin Splitter Cable

£5.20Unit price /Unavailable1 to 4 Ports Female/Male Connection Cable 4 Pin Splitter Cable

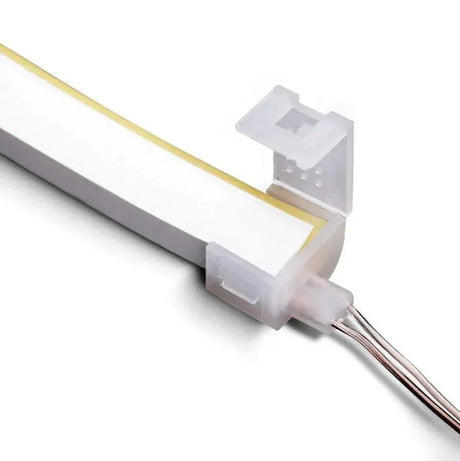

£7.30Unit price /UnavailableDigital RGB Neon Flex 10x20mm IP68 24V End Cap 3m Wire Connector

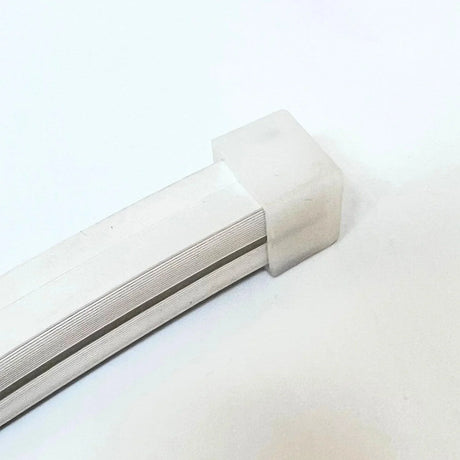

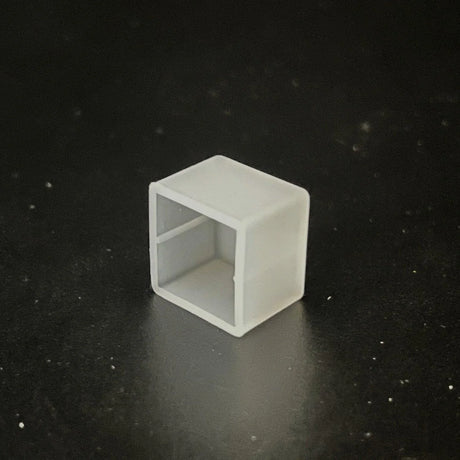

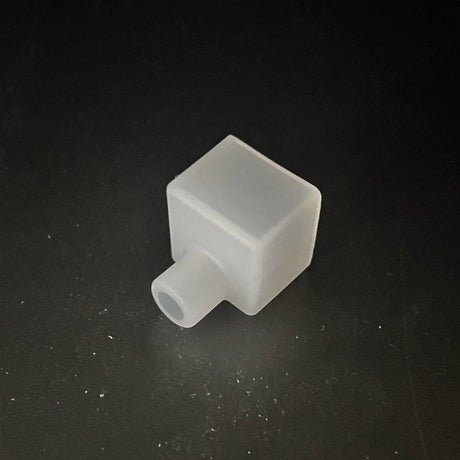

£12.85Unit price /UnavailableEnd Cap for for 12V/24V Addressable RGB LED Neon Flex 10x20mm IP68

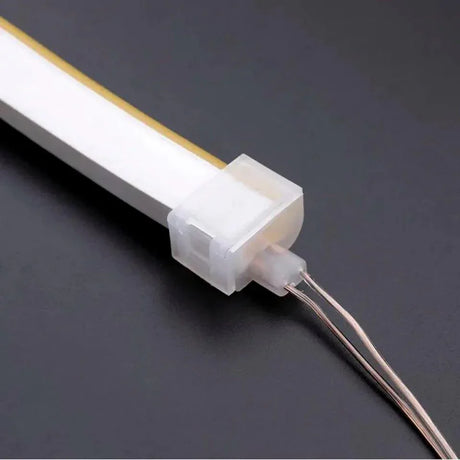

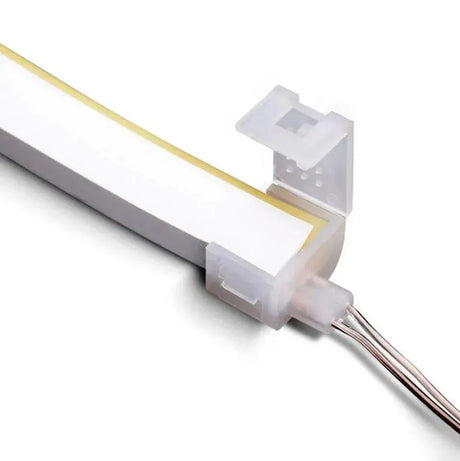

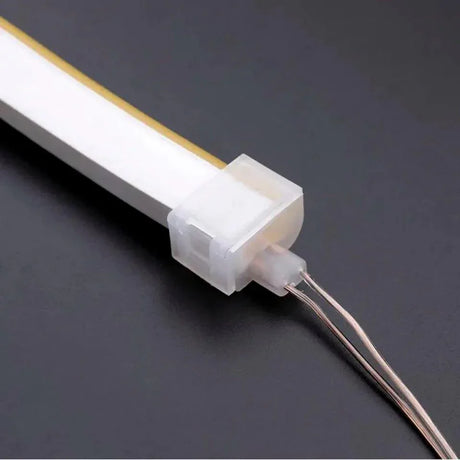

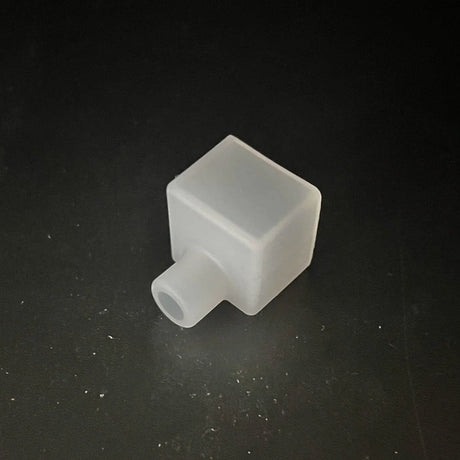

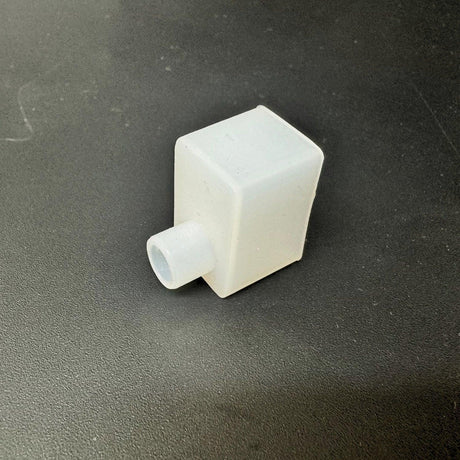

£9.85Unit price /UnavailableEnd Cap with Wire For Single Colour LED Neon Flex 24V 10x20mm IP68

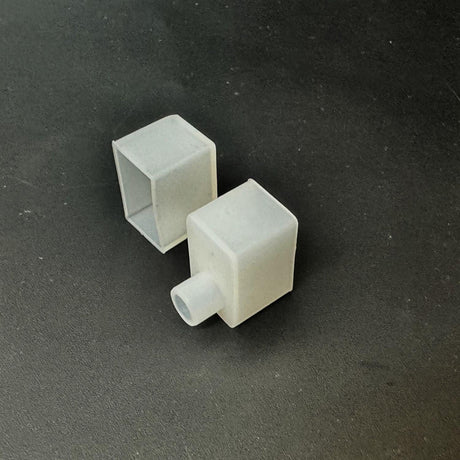

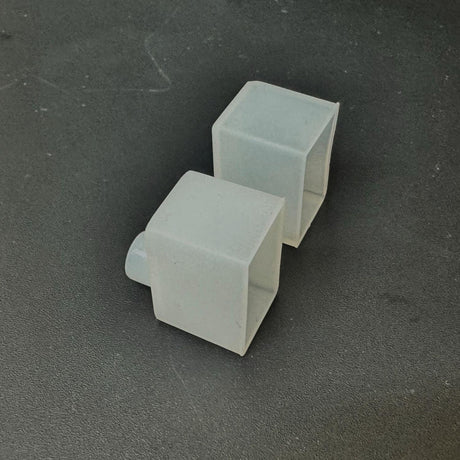

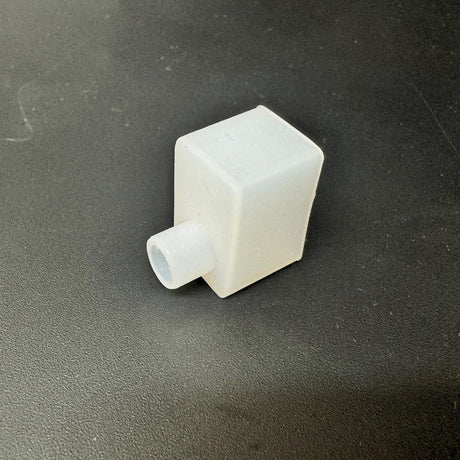

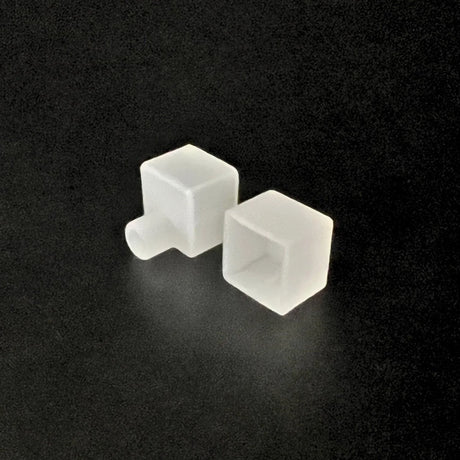

£12.85Unit price /UnavailableFront Cap & End Cap for for 12V/24V Addressable RGB LED Neon Flex 10x20mm IP68

£21.85Unit price /UnavailableFront Cap for 12V/24V Addressable RGB LED Neon Flex 10x20mm IP68

£14.85Unit price /UnavailableFront Cap with Wire For Single Colour LED Neon Flex 24V 10x20mm IP68

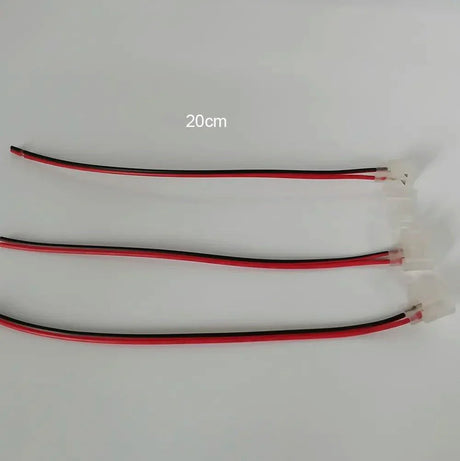

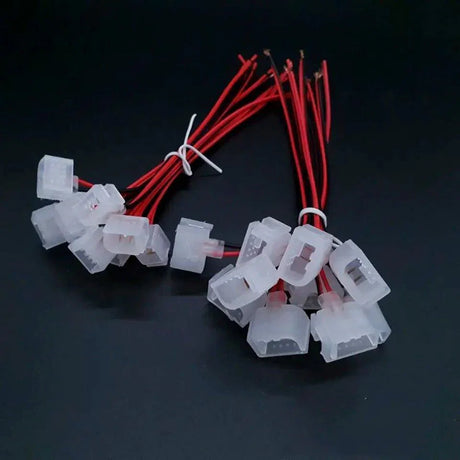

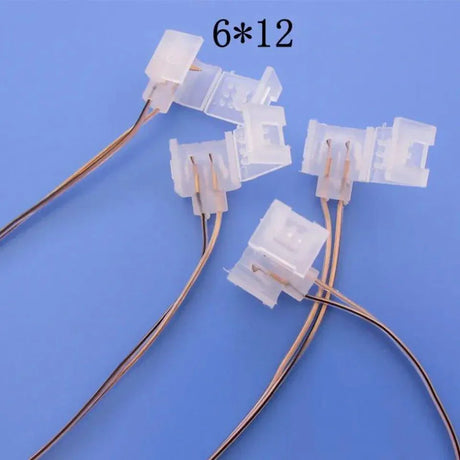

£12.85Unit price /UnavailableLED Neon Flex 12V/24V Non Welding Wire Connector for 6x12mm Single Colour Neon Flex

£6.75Unit price /UnavailableLED Neon Flex 8x16mm Non Welding Wire Connector for 12V/24V Single Colour Neon Flex

£9.85Unit price /UnavailableLED Strip 2 Core Extension Wire 17AWG for 2Pin 8mm LED Strip Connector DC Adapter 5 Metre

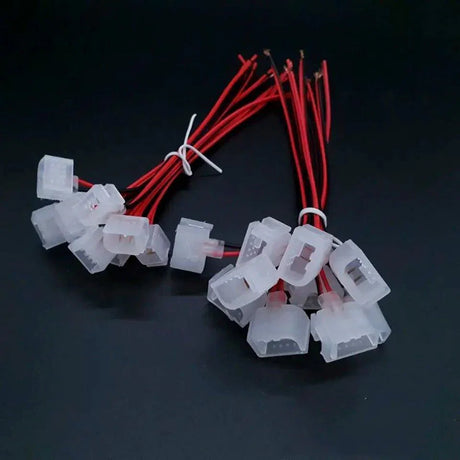

From £5.30Unit price /UnavailableLED Strip Accessories 5pcs 2Pin 10mm Clip to Wire

£7.04Unit price /UnavailableLED Strip Accessories 5pcs 2Pin Clip to DC Female Jack 10mm

£7.82Unit price /UnavailableLED Strip Accessories 5pcs Female DC Power Jack 2 pin

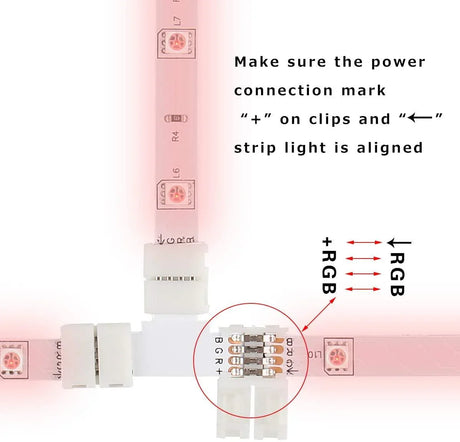

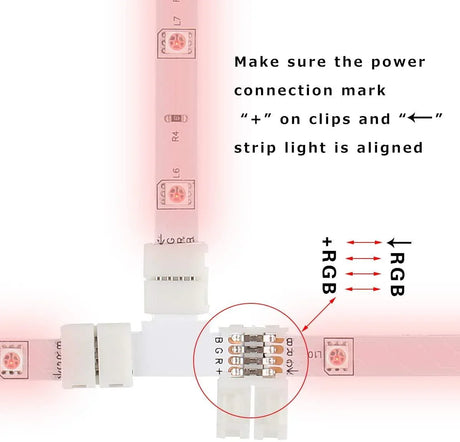

£10.83Unit price /UnavailableLED Strip Accessories 5pcs L Shape PCB RGB Connectors 4 pin 10mm

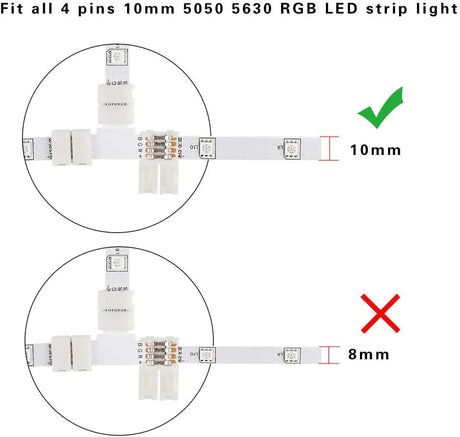

£5.78Unit price /UnavailableLED Strip Accessories 5pcs T-Shape PCB RGB Connectors 4 pin 10mm

£5.78Unit price /UnavailableSingle Colour Front Cap & End Cap 12V/24V LED Neon Flex 10x20mm IP68

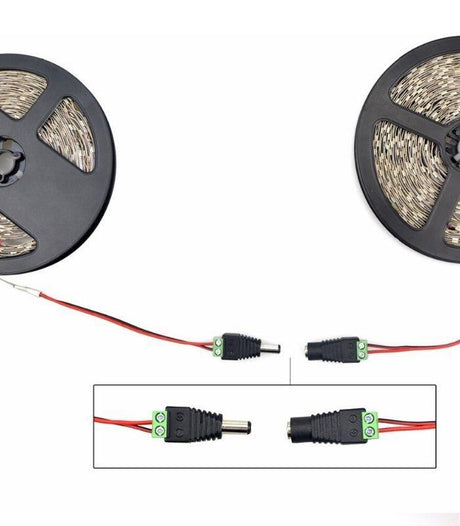

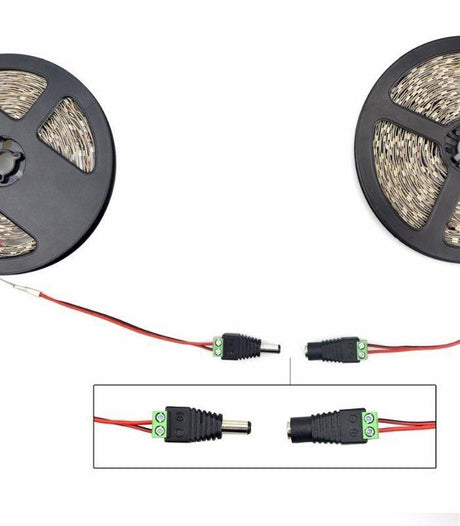

£19.85Unit price /Unavailable5 Sets 5.5mm x 2.1mm DC Male and Female Jack Connector for LED Strips

£11.95Unit price /Unavailable4 Pin RGB LED Strip & Neon Flex Connector 12V/ 24V with 0.5m Extension Cable

£6.83Unit price /Unavailable4 Pin RGB LED Strip Extension Wire Connector for RGB 5050 3528

From £6.30Unit price /Unavailable- From £2.85Unit price /Unavailable

5 Metre DC 12V/24V RGB LED Strip 4 Pin Soldless Connector Cables 5050 3528

£11.85Unit price /Unavailable- £8.68Unit price /Unavailable

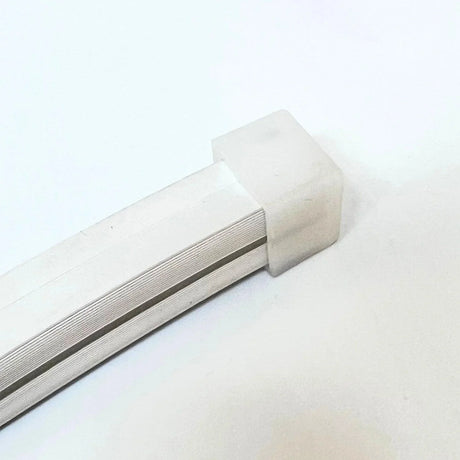

5 x End Cap for LED Neon Flex 14x25mm

£9.95Unit price /Unavailable5 x End Cap for LED Neon Flex 8x16mm

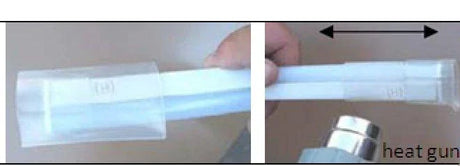

£8.95Unit price /UnavailableAdhesive Clear Heat Shrink Sleeving - 2:1 Weatherproof Heatshrink Tubing 16-25mm 1 Metre

From £6.85Unit price /UnavailableEnd Cap for COB LED Strip 220V 240V Neon Flex x 5

£8.95Unit price /UnavailableEnd Cap for Flat Shape LED Neon Flex 12x20mm x 5

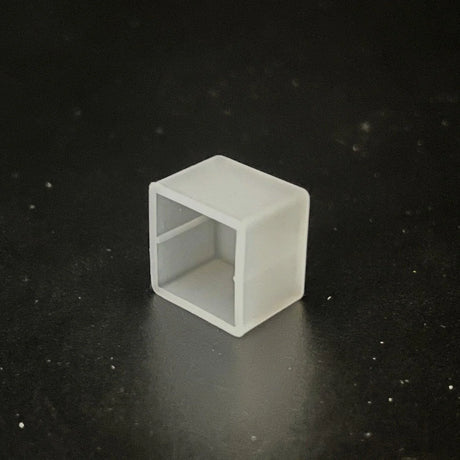

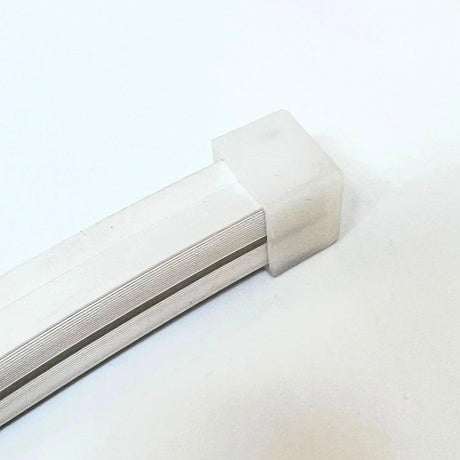

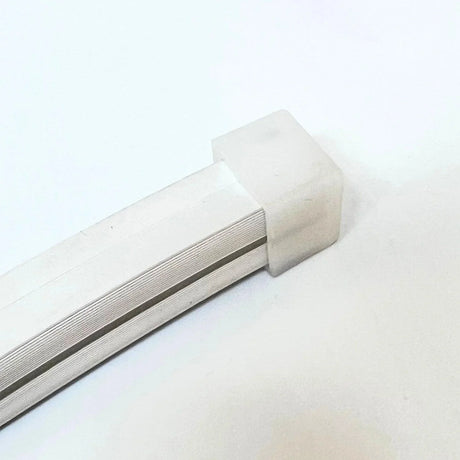

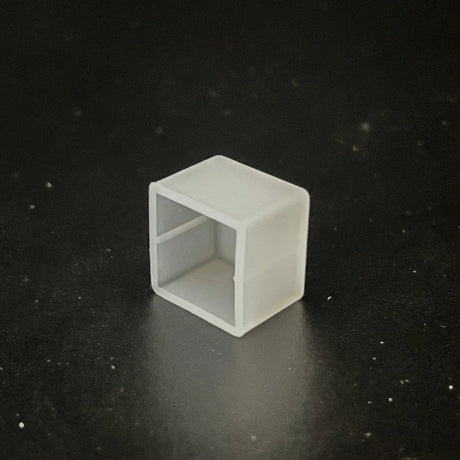

£7.75Unit price /UnavailableEnd Cap for LED Neon Flex 10x20mm

£2.75Unit price /UnavailableEnd Cap for LED Neon Flex 8x16mm x 5

£9.95Unit price /UnavailableEnd Cap for LED Neon Flex Flat Shape 16x16mm x 5

£9.85Unit price /UnavailableFront Cap & End Cap Set for LED Neon Flex Flat Shape 12x20mm x 5

£11.95Unit price /UnavailableFront Cap & End Cap Set for LED Neon Flex Flat Shape 16x16mm x 5

£15.75Unit price /UnavailableFront Cap for Flat Shape LED Neon Flex 12x20mm

From £7.75Unit price /Unavailable- £12.95Unit price /Unavailable

LED Neon Flex 220V 240V 16x16mm Single Colour Connector for 20cm cut Neon Flex

£12.95Unit price /UnavailableLED Neon Flex AC 220V 240V 8x16mm Single Colour Connector

£11.95Unit price /UnavailableLED Neon Flex AC 220V 240V 8x16mm Single Colour Wireless Connector

£11.95Unit price /UnavailableLED Neon Flex Single Colour 220V 240V 2 Pin 8x16mm Connector L , T , Straight

From £5.95Unit price /UnavailableLED Neon Flex Wireless AC 220V 240V 8x16mm Single Colour Dimmer Controller

£15.85Unit price /UnavailableLED Neon Flex Wireless Connector Cable DC 12V/ 24V 8x16mm Single Colour

£12.85Unit price /UnavailableLED Strip Accessories 5pcs + Shape PCB RGB Connectors 4 pin 10mm

£6.83Unit price /UnavailableLED Strip 220V 240V Controller For 5730 180 LEDs/m 2 Pin with UK Plug

£13.49Unit price /Unavailable

Essential Connection Systems

LED Strip Connectors

Our range of LED Strip Connectors provides reliable electrical connections for all types of LED strip lighting. From basic single-colour connections to complex RGB systems, our connectors ensure consistent power delivery and signal integrity throughout your installation.

By Connection Type

- Solderless LED Strip Connectors for quick, tool-free installation

- Quick-Connect LED Strip Adapters for rapid assembly and disassembly

- Heat-Shrink LED Connectors for permanent, weatherproof connections

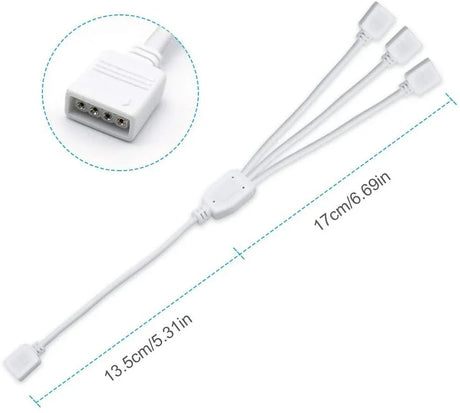

- LED Strip Splitters for creating branches and multi-direction runs

By Strip Compatibility

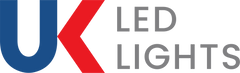

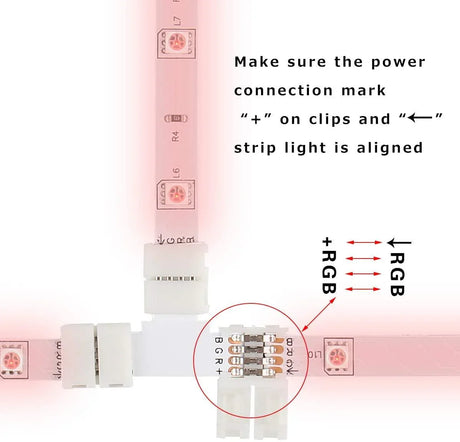

- RGB LED Strip Connectors with 4-pin configuration

- 4-Pin LED Strip Connectors for standard RGB installations

- 5-Pin RGBW LED Connectors for RGBW and RGBWW systems

- 5050 RGB LED Strip Connectors specifically designed for 5050 LED strip compatibility

By Environmental Protection

- Waterproof LED Strip Connectors for outdoor and moisture-prone installations

- IP65/IP68 Waterproof Connectors offering different levels of moisture protection

- LED Strip Connectors for Outdoor Use with UV-resistant materials

- Outdoor LED Strip Connectors designed to withstand temperature fluctuations

Extension & Power Cables

Our LED Extension Cables allow you to bridge gaps, navigate obstacles, and extend your lighting installations while maintaining proper power and signal delivery. Available in various lengths and configurations to suit any project requirement.

Standard Extensions

- Single-colour extension cables in various lengths

- 4-Pin RGB Extension Cables for RGB strip systems

- Heavy-duty cables for higher current applications

- Pre-terminated cables with compatible connectors

Specialty Power Solutions

- LED Strip Power Supply cables and adapters

- LED Strip Power Adapters for connecting to various power sources

- Male-to-Female LED Adapters for system extensions

- Distribution cables for multi-point power injection

Connection Accessories

Complete your connection system with specialized components that enhance functionality and simplify complex installations.

Junction Components

- LED Strip Corner Connectors for navigating 90° turns

- LED Strip Joiner Clips for straight connections between strips

- T-connectors for creating branches and splits

- Cross connectors for intersection points

Adapter Solutions

- LED Strip Light Adapters for transitioning between different systems

- LED Strip Adapters for connecting strips to controllers

- Protocol converters for integrating different LED technologies

- Voltage step-down adapters for mixed-voltage systems

Mounting & Installation Solutions

Mounting Hardware

Secure your LED strips precisely where you want them with our range of professional mounting solutions. From discreet clips to specialized brackets, we provide the hardware needed for stable, long-lasting installations.

Clip Systems

- LED Strip Light Clips for basic surface mounting

- LED Strip Clips in various sizes for different strip widths

- LED Strip Mounting Clips with screw holes for permanent installation

- Silicone-cushioned clips for reduced vibration

Specialized Mounts

- Adjustable-angle brackets for directional lighting

- Magnetic mounts for temporary or repositionable installations

- Suspension systems for pendant-style lighting effects

- Recessed mounting hardware for flush installations

Finishing Components

Create a professional, polished appearance while protecting your LED installation with our range of finishing accessories designed for both functionality and aesthetics.

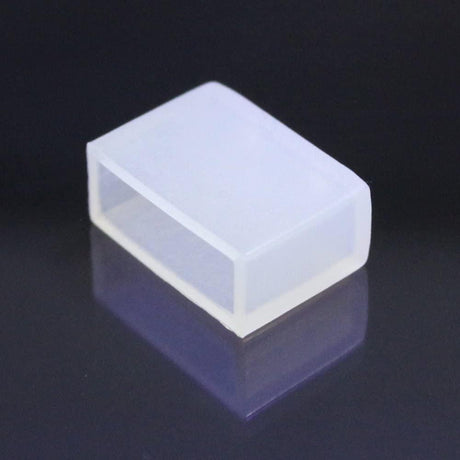

End Caps & Terminators

- LED Strip End Caps for clean termination points

- Silicone LED End Caps for flexible and waterproof applications

- Colour-matched end caps for seamless integration

- Combination end caps with power feed-through capability

Protection & Enhancement

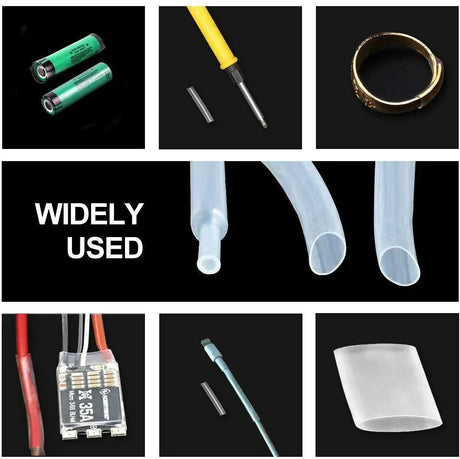

- LED Strip Heat Shrink Tubing for connection protection

- Diffuser covers for softer light distribution

- Anti-UV sleeves for prolonged outdoor performance

- Cable management solutions for organized installations

Advanced Installation Tools & Accessories

Installation Tools

Professional-grade tools that simplify the installation process, ensure proper alignment, and create clean, precise results even in challenging applications.

- Specialized cutting tools for clean LED strip termination

- Alignment guides for perfect positioning

- Testing equipment for verifying connections before final installation

- Professional-grade installation kits with essential components

Control & Power Components

Essential accessories for powering and controlling your LED lighting systems, ensuring optimal performance, versatility, and user convenience.

- LED Strip Dimmer Controllers for adjustable brightness

- Remote control systems for convenient operation

- Smart controllers for integration with home automation

- Signal amplifiers for extended installations

Choosing the Right Accessories

Compatibility Considerations

Voltage Requirements

Select accessories that match your LED system's voltage. Our range includes 12V/24V LED Strip Connectors as well as options for 48V systems, ensuring proper electrical compatibility for safe, reliable operation.

Strip Type & Dimensions

Different LED strips require specific connector types. Standard single-colour strips typically use 2-pin connectors, while RGB LED Connectors require 4-pin connections and RGBW strips need 5-pin connectors. Always verify the physical dimensions and connection layout of your LED strips before selecting accessories.

Environmental Protection

For outdoor or moisture-prone installations, choose Waterproof LED Connectors with appropriate IP ratings. IP65 provides protection against water jets, while IP68 offers full submersion protection for underwater applications.

Application-Specific Solutions

Architectural Lighting

For architectural applications, consider LED Strip Connectors for Ceiling Lighting and LED Connectors for Ceiling Coving that provide discreet, professional results while accommodating building contours and structural features.

Signage & Display

LED Strip Connectors for Signage and LED Connectors for Signage are designed for the specific requirements of commercial displays, offering secure connections while maintaining clean lines and visual consistency.

Automotive & Transportation

For vehicle applications, LED Strip Connectors for Automotive Lighting and LED Connectors for Automotive Lighting provide vibration resistance and compact design suited to the unique challenges of mobile installations.

Outdoor & Landscape

Landscape lighting requires durability and weather resistance. Our outdoor-rated connectors and accessories feature enhanced UV protection, temperature tolerance, and moisture resistance for reliable long-term performance.

Installation Best Practices

Planning & Preparation

Successful LED installations begin with thorough planning. Calculate power requirements, map connection points, and identify potential challenges before beginning the physical installation. Ensure you have all necessary accessories and allow additional length for connectors and adaptation points.

Connection Security

For reliable long-term performance, ensure all connections are secure and protected. Use Solderless LED Strip Connectors according to their design specifications, applying appropriate pressure for clip styles and ensuring full insertion for push-in varieties.

Environmental Protection

In outdoor or high-humidity environments, use Waterproof LED Strip Connectors and apply additional silicone sealant at connection points for maximum protection. Consider heat-shrink tubing as an additional protective layer for critical connections.

Stress Relief & Support

Provide adequate support for connection points to prevent mechanical stress on the solder joints or connectors. Use LED Strip Mounting Clips near connection points and avoid tension on cables that could compromise connection integrity.

Frequently Asked Questions

What mounting channels fit 14x26mm neon flex tubes

Use an aluminium mounting channel made for 14x26mm neon flex, or choose a channel with an internal opening slightly larger so the silicone sleeve fits without squeezing. Make sure the channel uses matching clips or retainers so the flex stays secure.

How to waterproof end caps for outdoor neon flex lights

Cut the neon flex square, dry the end fully, then fit the correct end cap and seal it with outdoor grade silicone. Seal the cable exit as well and let it cure fully before you power it on.

Best connectors for RGB neon flex strip joins

Use waterproof 4 pin connectors rated for outdoor use and sized for your cable thickness and current. For the most reliable join outdoors, use a sealed connector housing or a soldered join covered with adhesive lined heat shrink.

How to cut and seal silicone LED neon strips safely

Turn power off, cut only at the marked cut point, and use a sharp blade for a clean edge. Fit an end cap and seal it with outdoor grade silicone so water cannot wick inside.

Recommended power supplies for long neon flex runs up to 10m

Check the watts per metre, multiply by your total metres, then add 20 to 30 percent headroom. Choose a constant voltage power supply that matches the strip voltage and keep it in a dry, ventilated, weatherproof location.

What clips secure neon flex to fences without drilling?

Use outdoor rated adhesive mounting clips on a clean, dry surface, or strap the flex with UV stable cable ties through fence gaps if the fence design allows. Avoid relying only on the flex’s own adhesive backing outdoors.

Which aluminium profiles diffuse LED strips evenly on deck edges?

Use an aluminium channel with an opal diffuser cover so you soften hotspots and protect the strip. A deeper profile usually diffuses better than a shallow one.

How do stainless steel brackets resist rust in wet gardens?

Choose corrosion resistant stainless steel, and use matching stainless fixings so you reduce rust risk. Keep dirt and standing water off the fittings where possible.

Why use silicone end caps with sealant on cut neon flex ends?

They block water from entering the silicone sleeve and reaching the LED tape inside. The sealant fills tiny gaps so moisture cannot creep in over time.

What 2 pin quick connectors join outdoor strips at corners safely?

Use waterproof 2 pin connectors that match your strip width, wire size, and current rating. Keep polarity correct and protect the connection inside a sealed junction or connector housing.

How do bifurcation plugs split power for branched garden paths?

They split one power feed into two branches so you can run separate sections from the same driver. Make sure the combined load stays within the driver rating and protect each branch with the right fuse.

Which adapters link 12V or 24V strips to waterproof drivers?

Use adapters that match the driver output connector and the strip input lead, with correct polarity and a current rating above your load. For outdoor installs, use waterproof inline connectors instead of open plug adapters.

What heat shrink tubing prevents joint corrosion in rain?

Use adhesive lined heat shrink because it seals the joint as it shrinks and helps stop water getting to the copper. Apply it over a solid connection and shrink it fully so the adhesive flows at both ends.

How to choose clips for 6 to 20mm neon widths on curves

Match the clip size to the neon flex width, and use more clips on tight curves so the flex does not lift. Keep bends smooth and do not force the flex into a radius it does not support.

How do I choose the right connector type for my LED strip?

Match the connector to your strip width and pin count, and make sure it suits your strip type like single colour, CCT, RGB, RGBW, or addressable. Also match the connector current rating and IP rating to where you will install it.

Can I connect different types of LED strips together?

Do not connect different control types directly because they use different wiring and controllers. You can run them from the same power supply only if they share the same voltage and you stay within the power supply rating.

Are solderless connectors reliable for permanent installations?

They can work well indoors or in sheltered areas if you secure the cable so it cannot pull on the joint. For outdoor or high vibration installs, use a sealed waterproof connector or a soldered join with proper sealing.

How many mounting clips do I need for a secure LED strip installation?

Use a clip about every 30 to 50 cm on straight runs, and add extra clips at corners and joins. For heavier neon flex or exposed outdoor runs, use closer spacing.

What’s the difference between IP65, IP67, and IP68 rated connectors?

IP65 handles rain and water spray, IP67 handles short term immersion, and IP68 is designed for deeper or longer immersion based on the maker’s rating. Even with higher ratings, you still need to seal cable entry points correctly.

How do I extend my LED strip installation without voltage drop?

Feed long runs in parallel and inject power at more than one point so the far end stays bright. Use thicker cable for longer distances and keep power supplies close to the load when you can.

Can I reuse LED strip connectors if I need to modify my installation?

Yes, if the connector still grips firmly and the contacts look clean with no corrosion. Replace it if the latch feels loose, the pins look damaged, or the connection has heated up before.

Do I need special tools to install LED strip accessories?

You usually only need basic tools like a tape measure, cutter, wire stripper, and screwdriver. A heat gun helps if you use adhesive lined heat shrink for outdoor sealing.