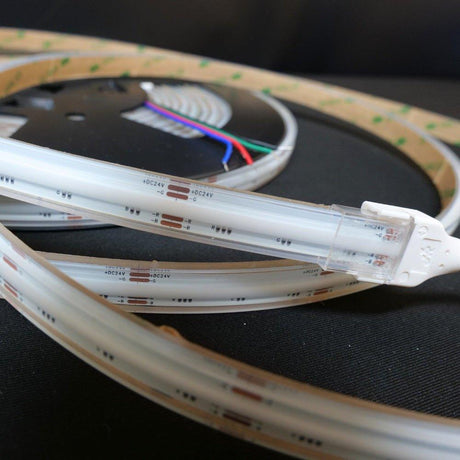

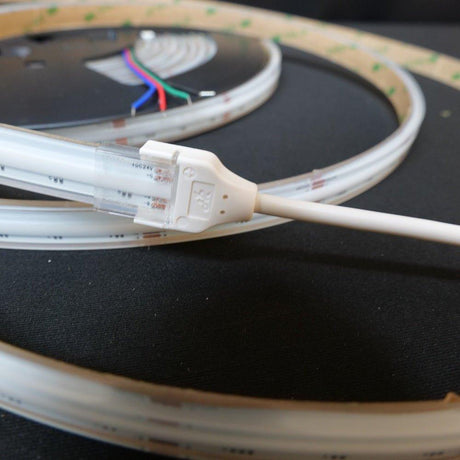

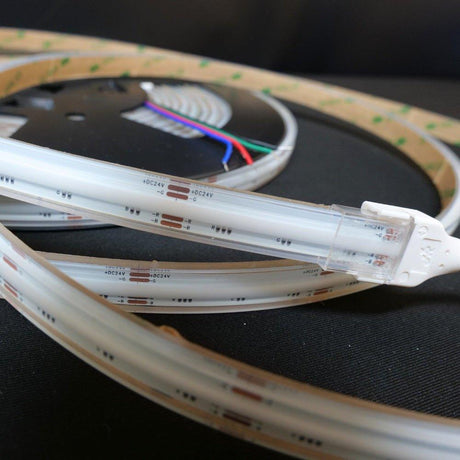

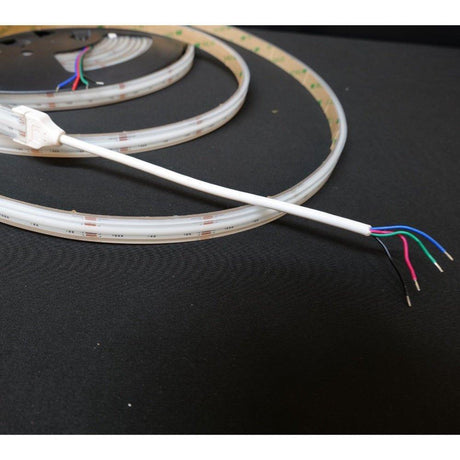

Addressable Digital Pixel RGB COB Strip 24V IP68 Waterproof 720 LEDs/m WS2811

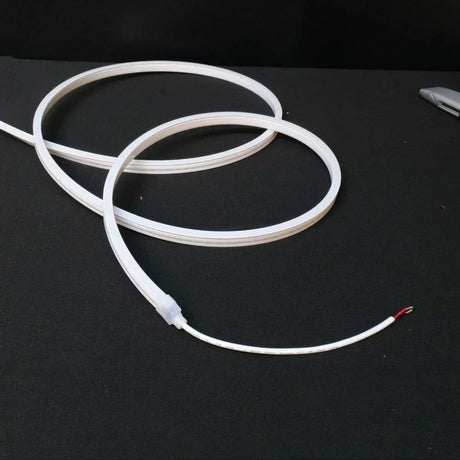

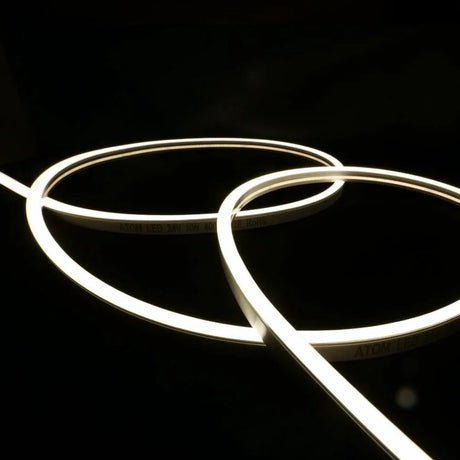

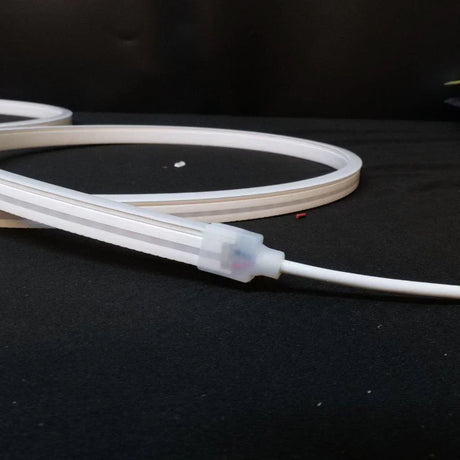

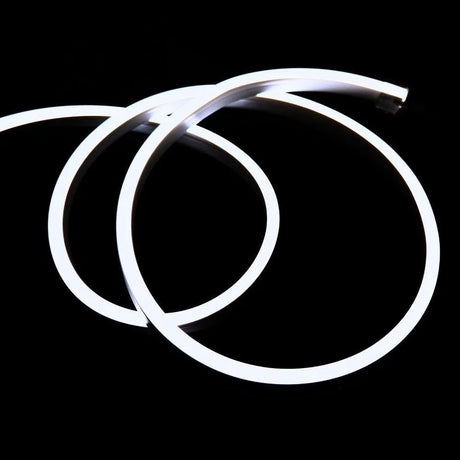

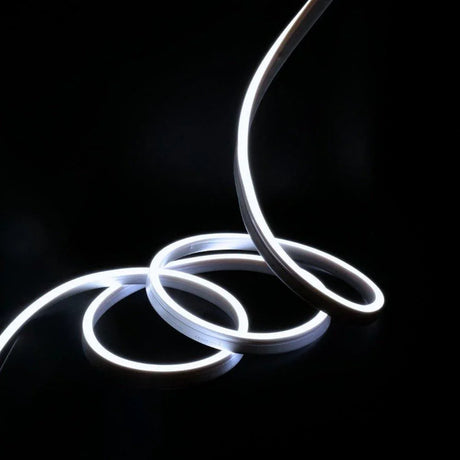

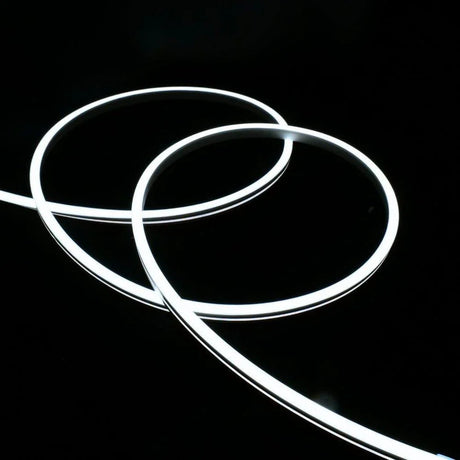

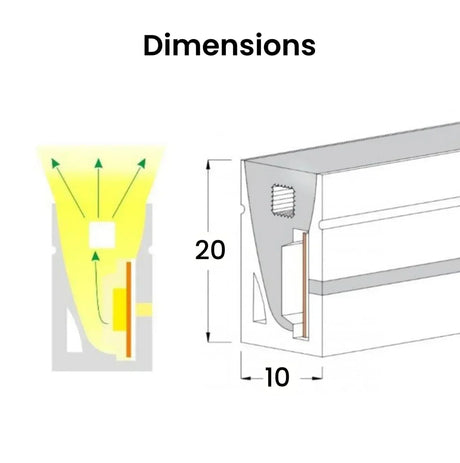

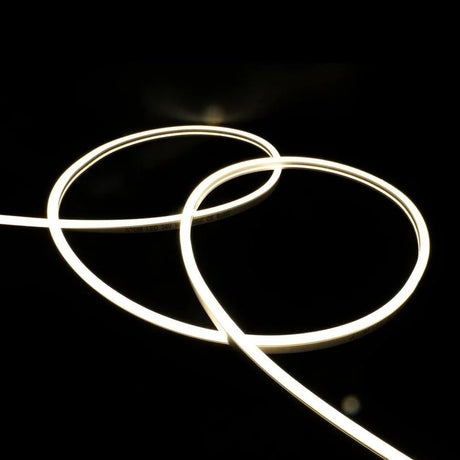

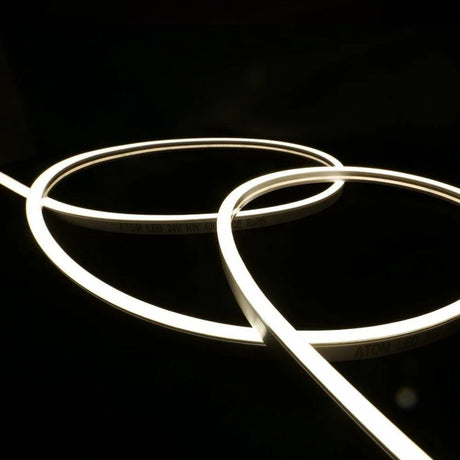

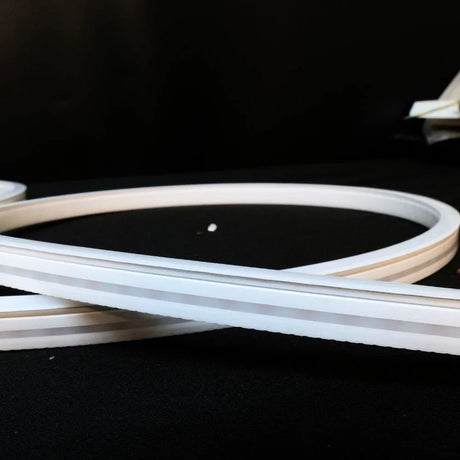

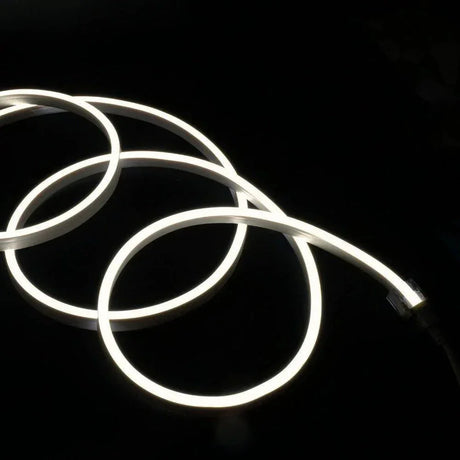

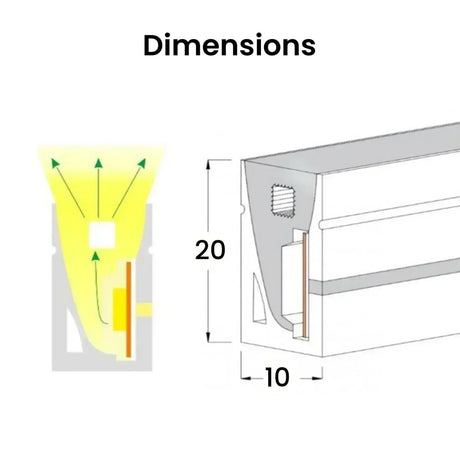

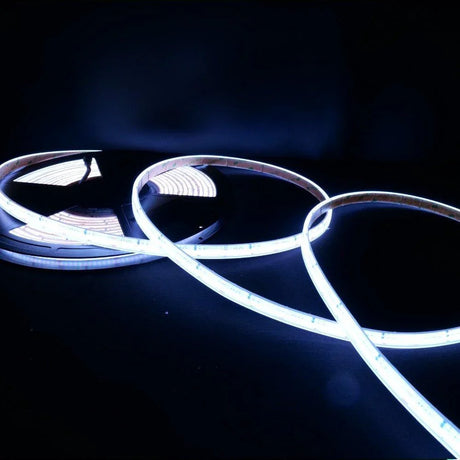

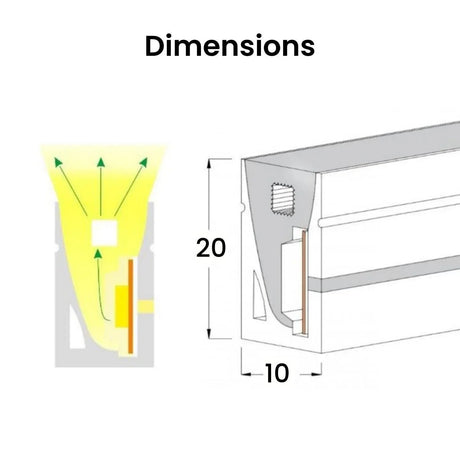

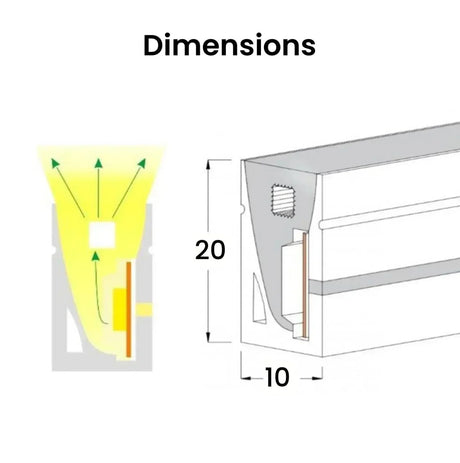

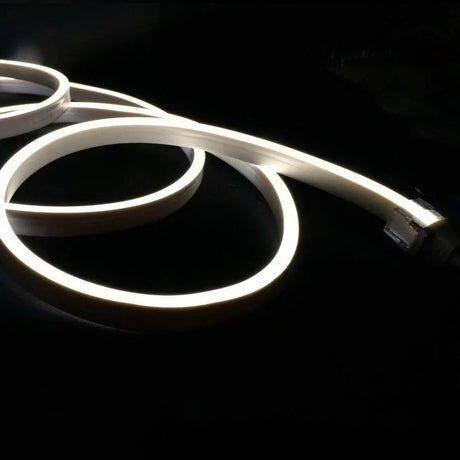

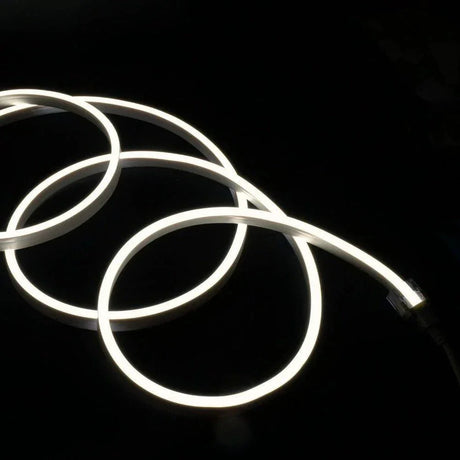

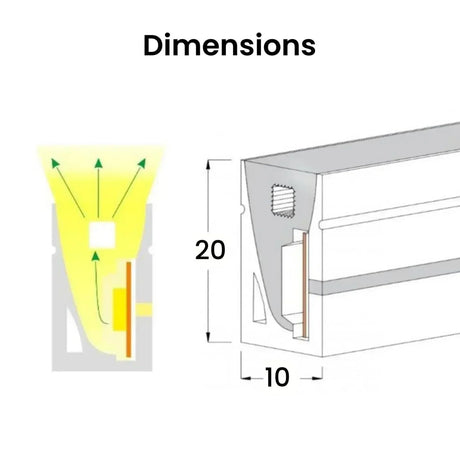

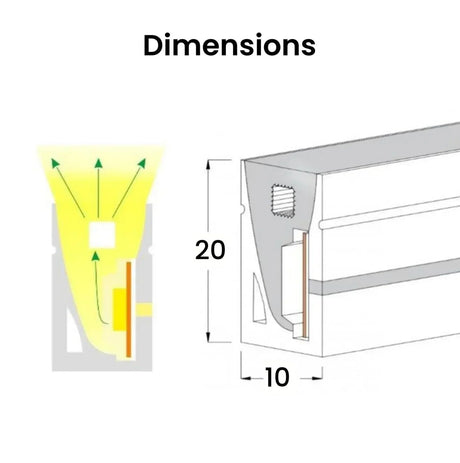

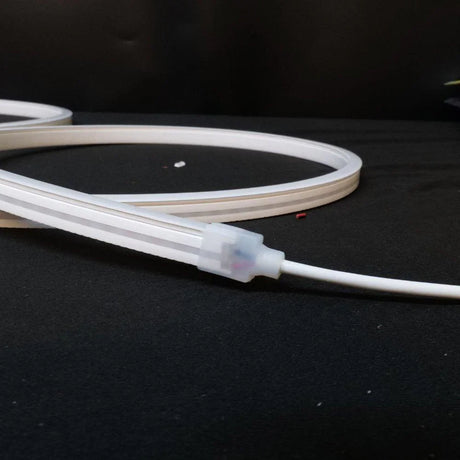

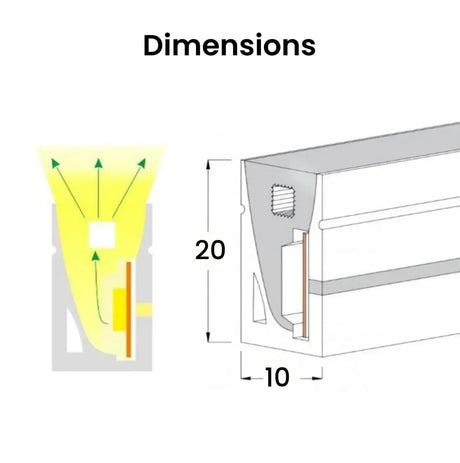

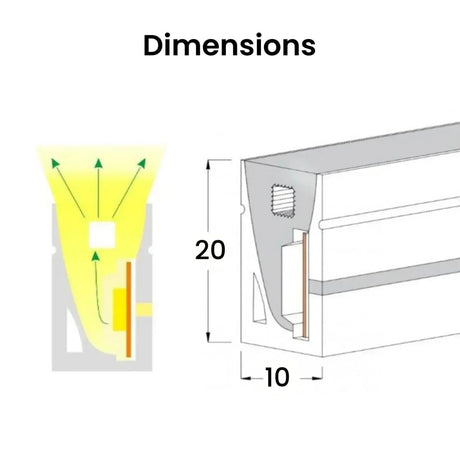

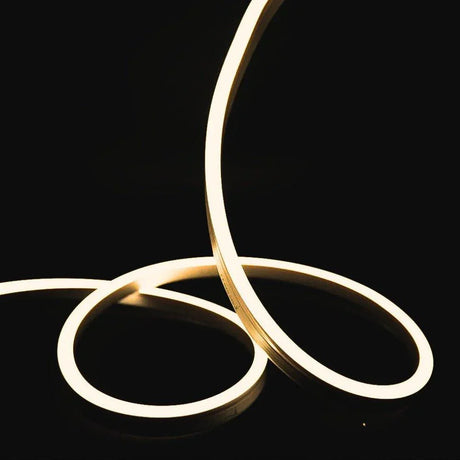

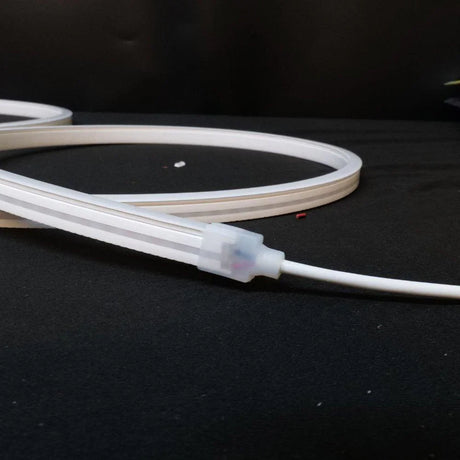

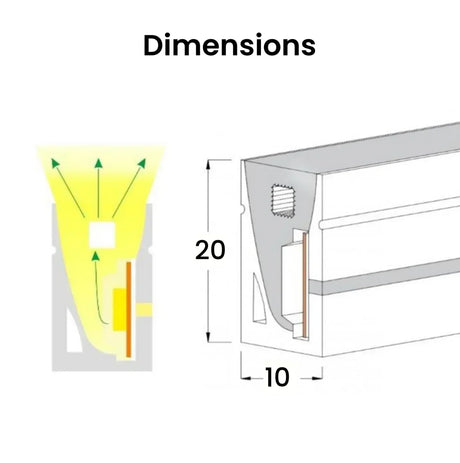

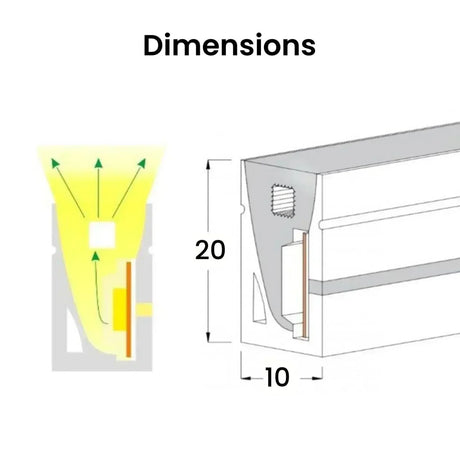

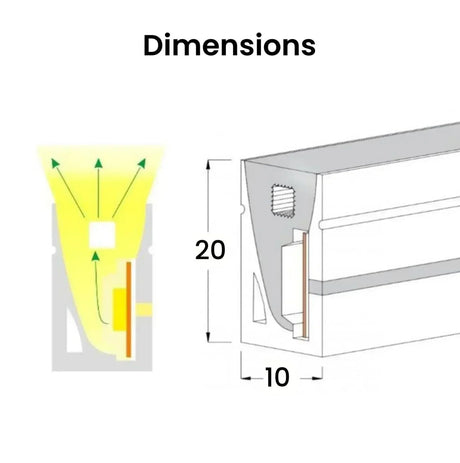

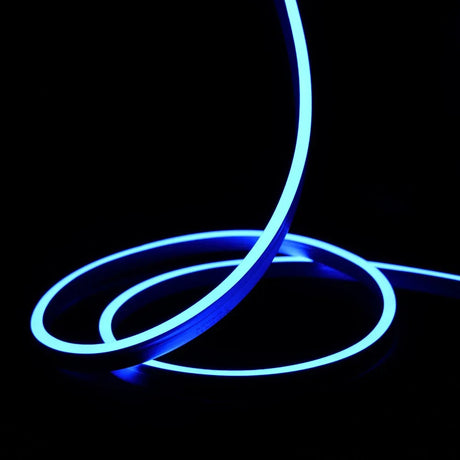

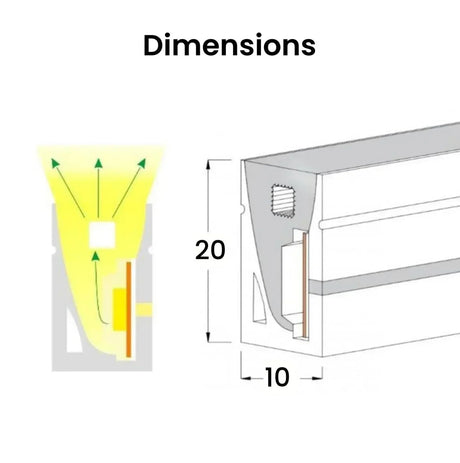

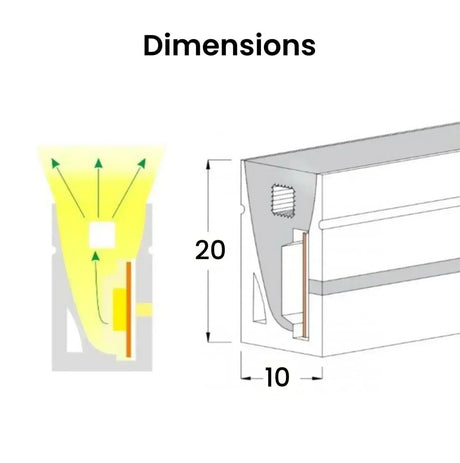

From £117.50Unit price /UnavailableCool White LED Neon Flex 6000K 24V 10x20mm IP68 Waterproof 12.5cm Cut

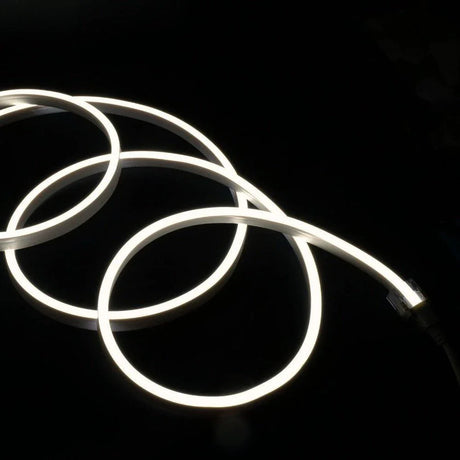

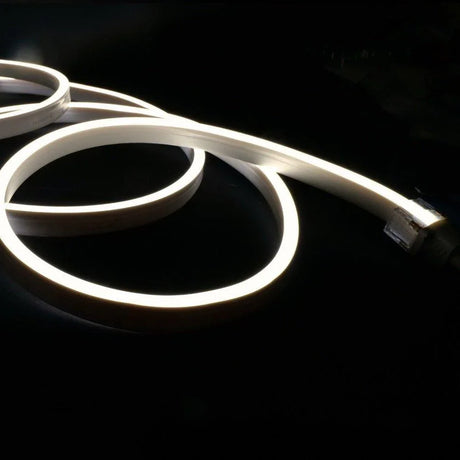

From £24.52Unit price /UnavailableCool White Neon Flex 6000K 24V 10x20mm IP67 Waterproof 20m

From £21.85Unit price /UnavailableNatural White LED Neon Flex 4000K 24V 10x20mm IP68 Waterproof 12.5cm Cut

From £24.52Unit price /UnavailableNatural White Neon Flex 4000K 24V 10x20mm IP67 Waterproof 12.5cm Cut

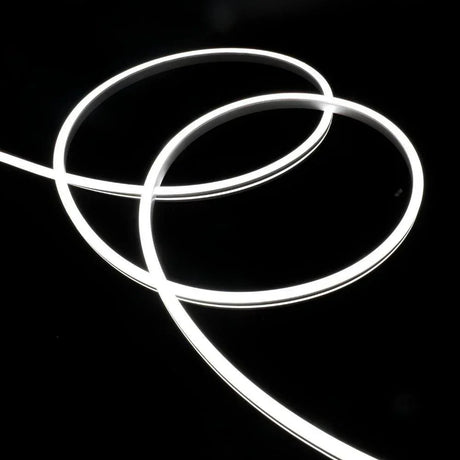

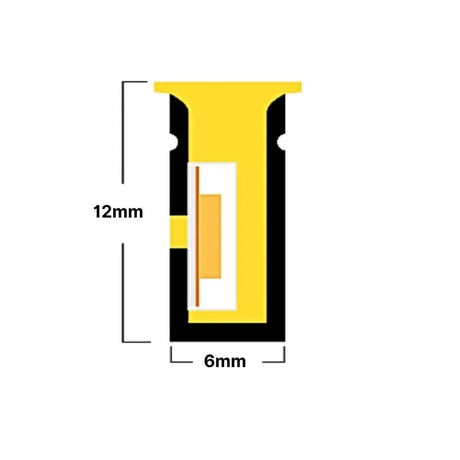

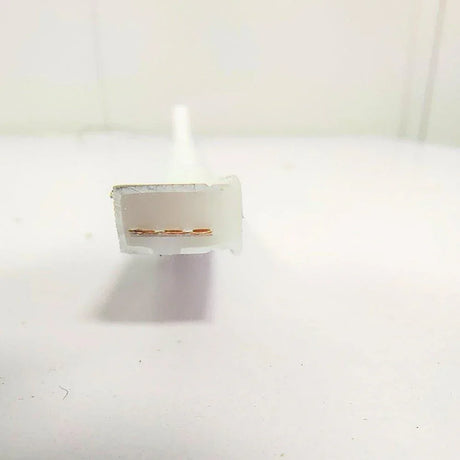

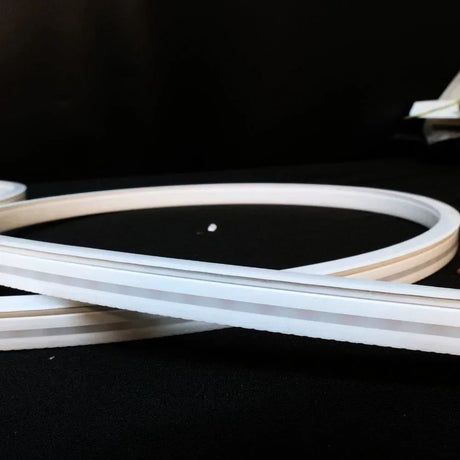

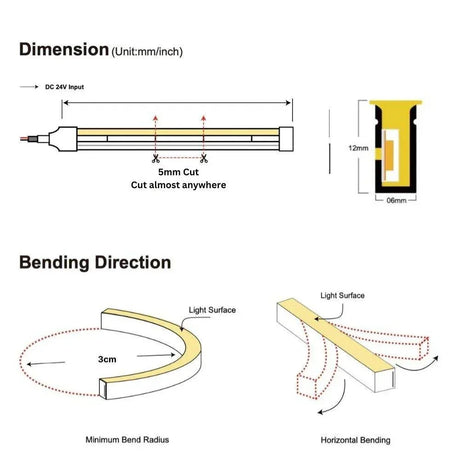

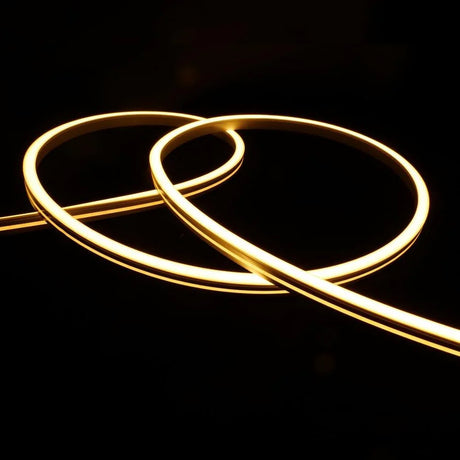

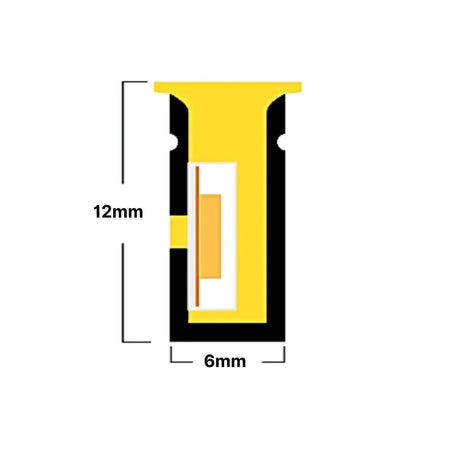

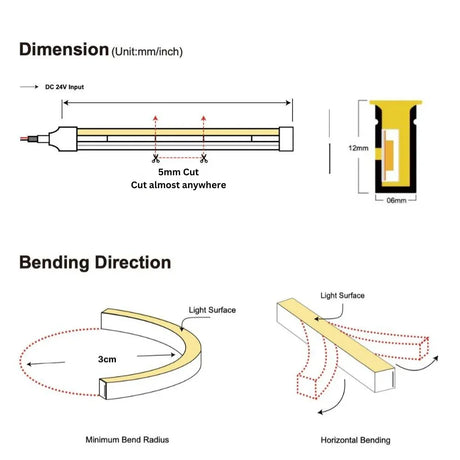

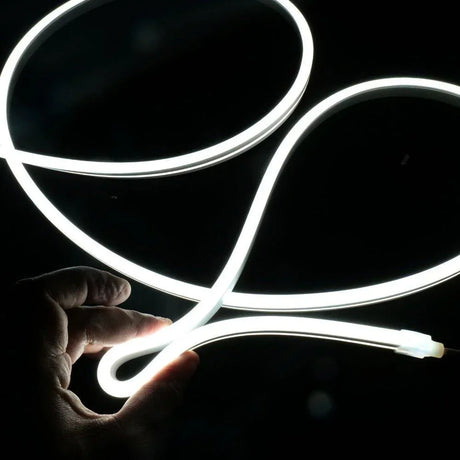

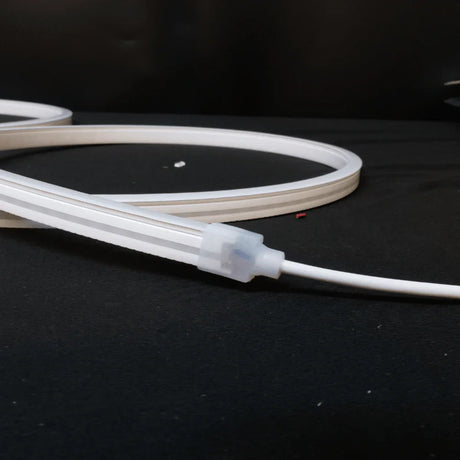

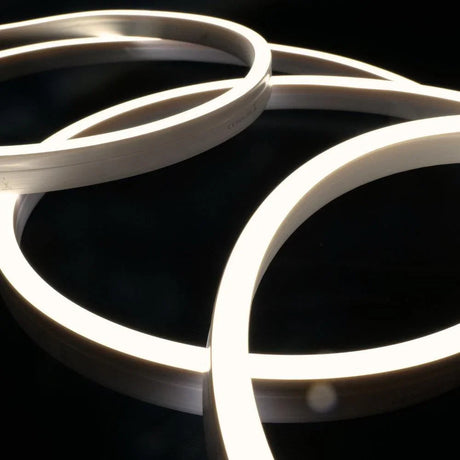

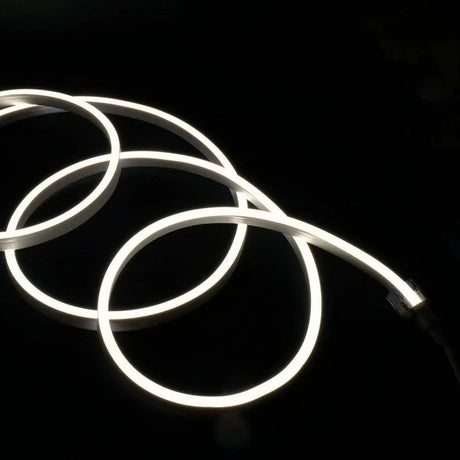

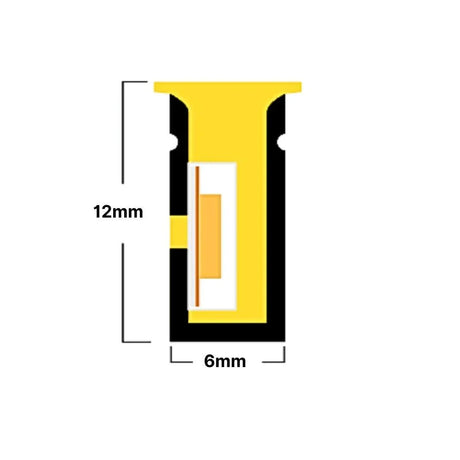

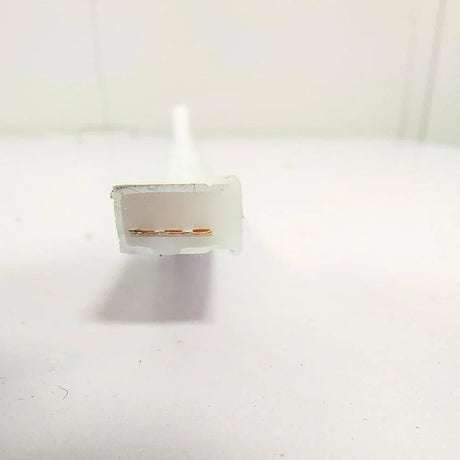

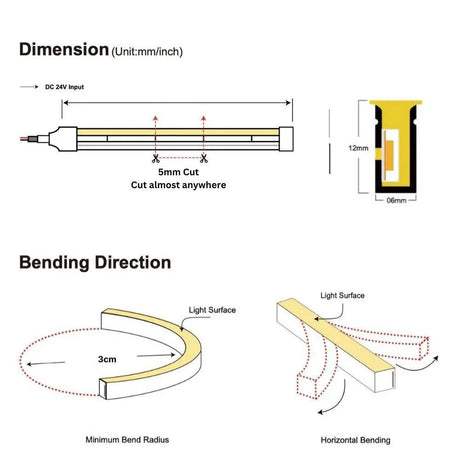

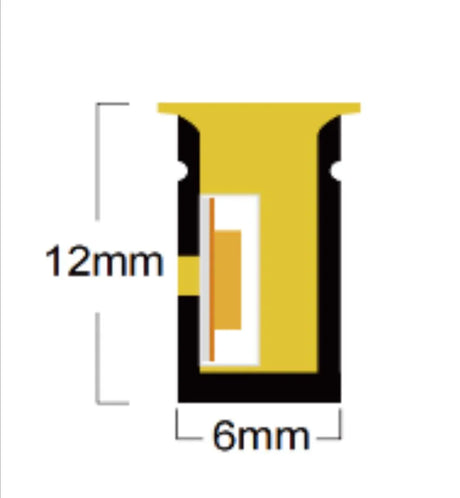

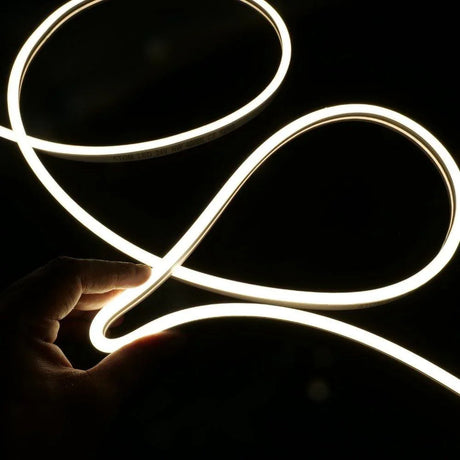

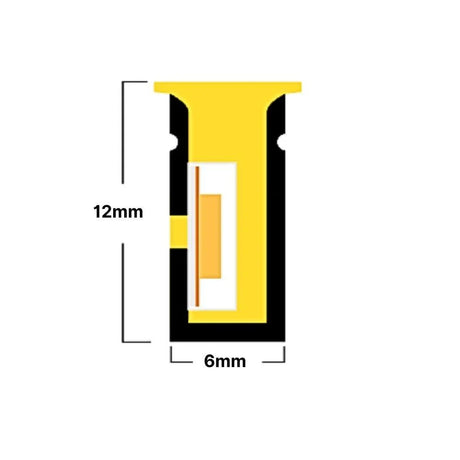

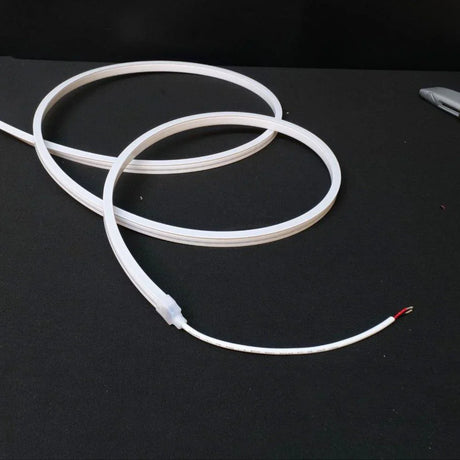

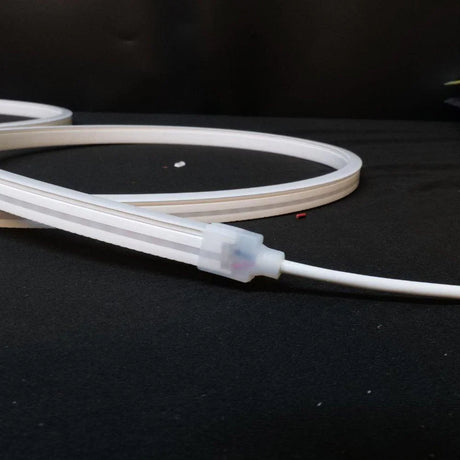

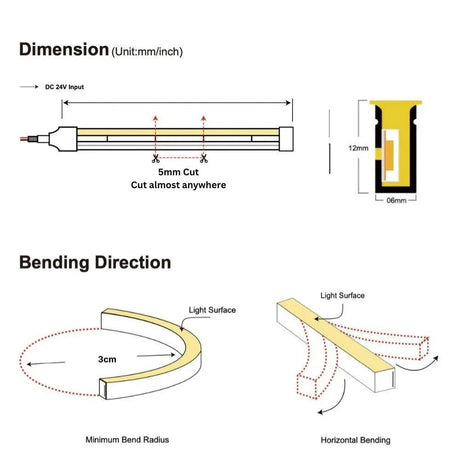

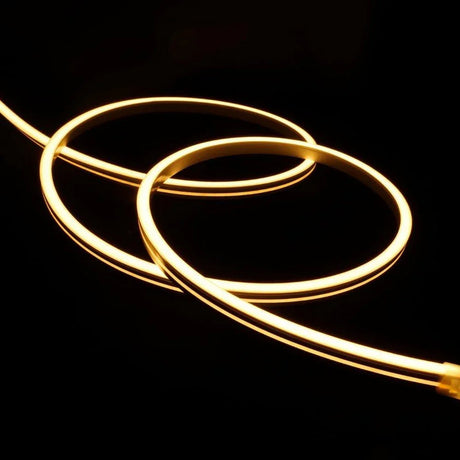

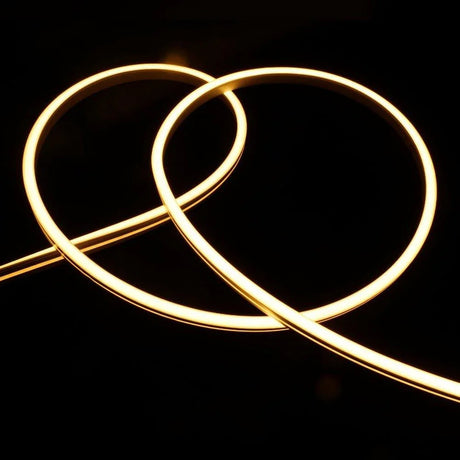

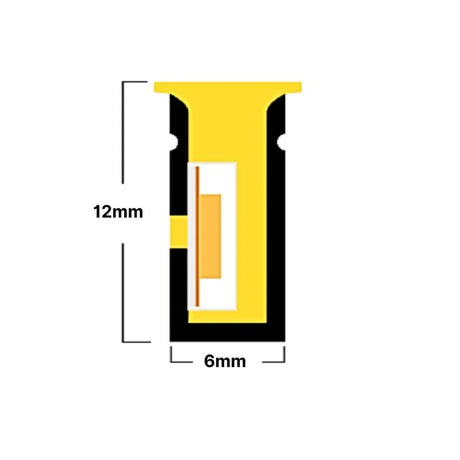

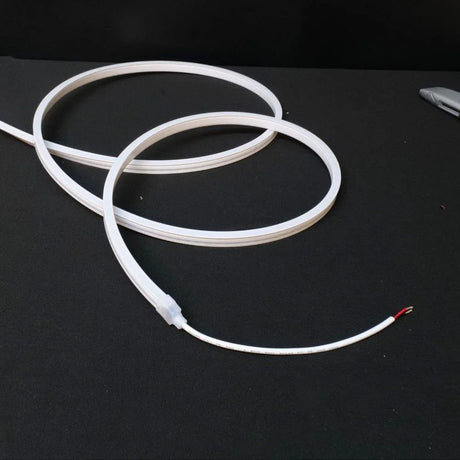

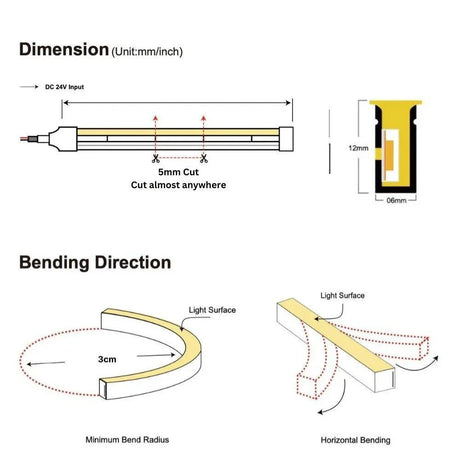

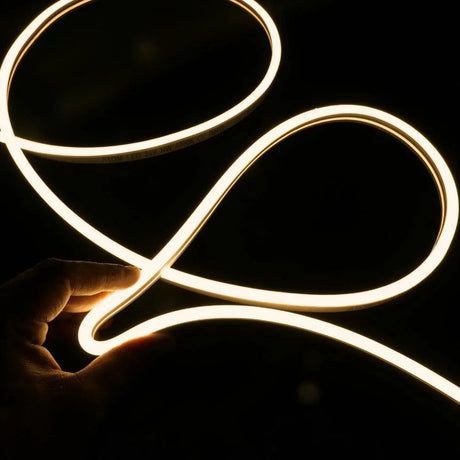

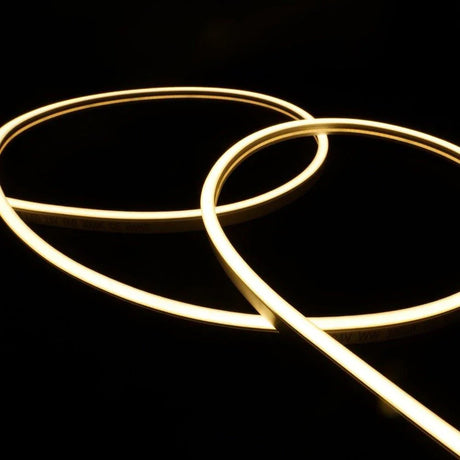

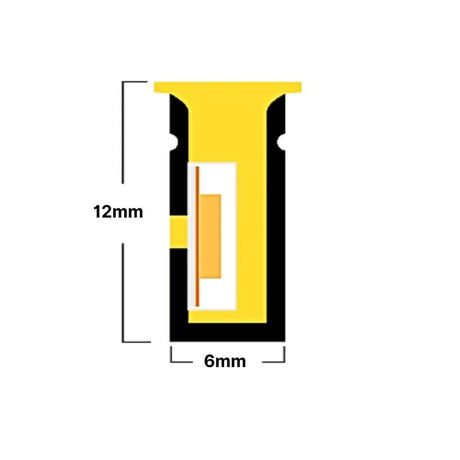

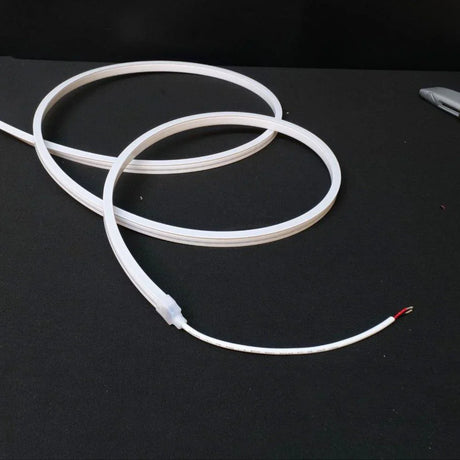

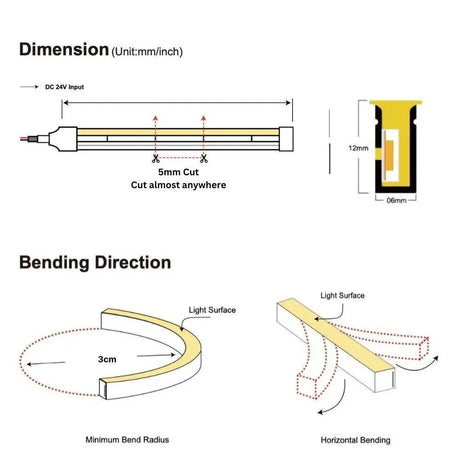

From £21.85Unit price /UnavailableNatural White Neon Flex 4000K 24V 6x12mm IP67 Waterproof Free Cut

From £19.85Unit price /UnavailableNatural White Neon Flex 4000K 48V 10x20mm IP67 Waterproof 50m

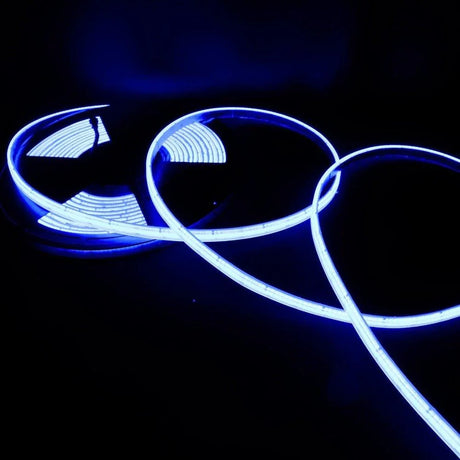

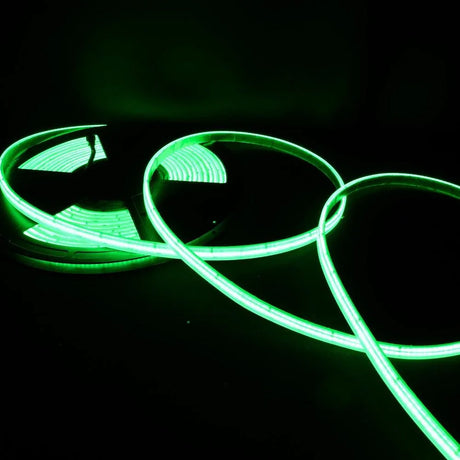

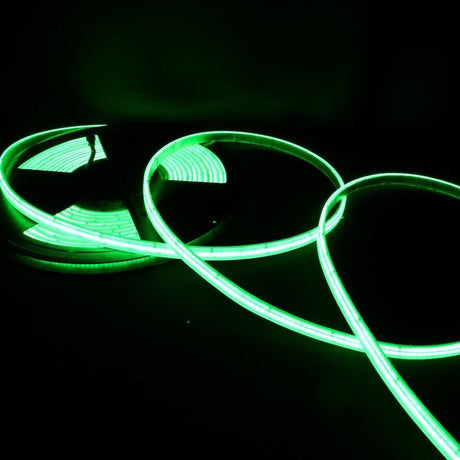

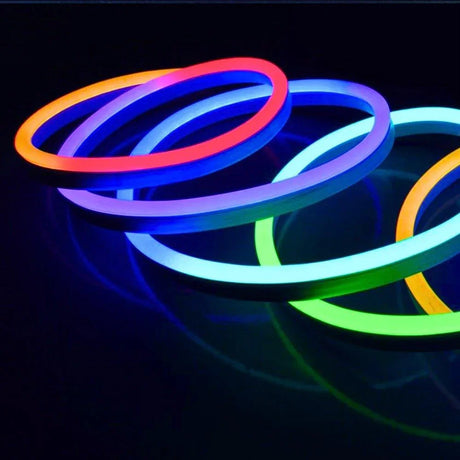

From £21.85Unit price /UnavailableRGB COB LED Strip 24V IP68 Waterproof 840 LEDs/m 5cm Cut

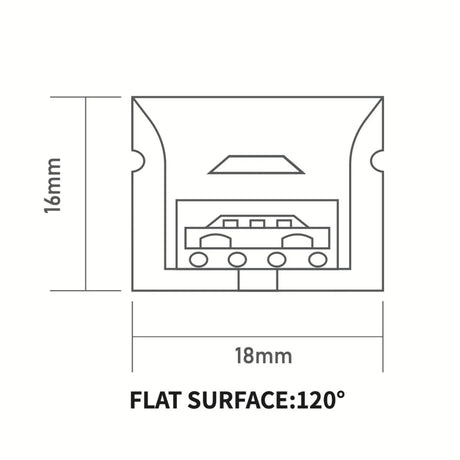

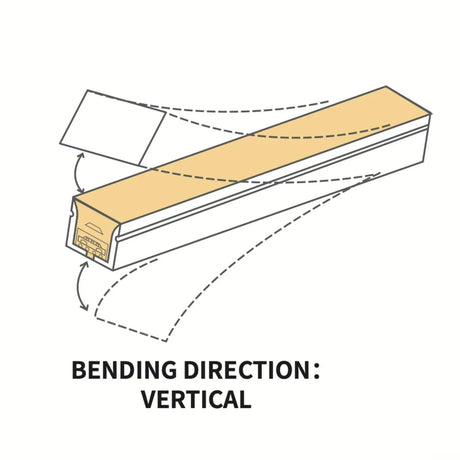

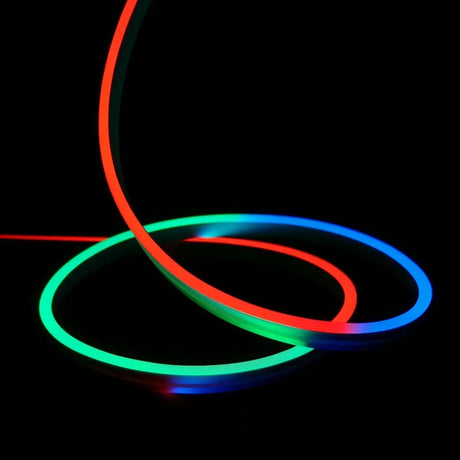

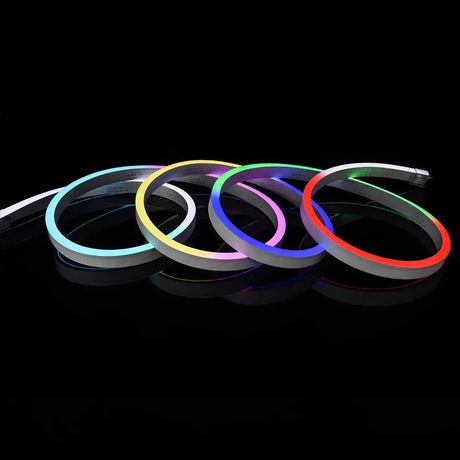

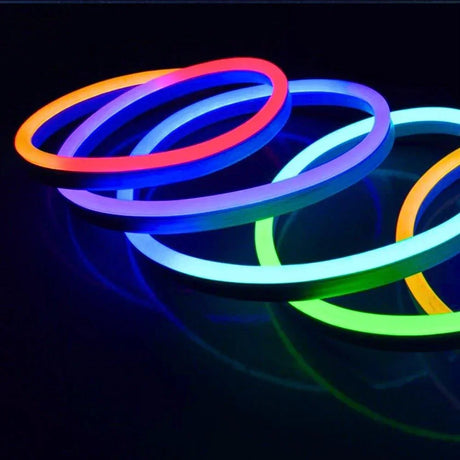

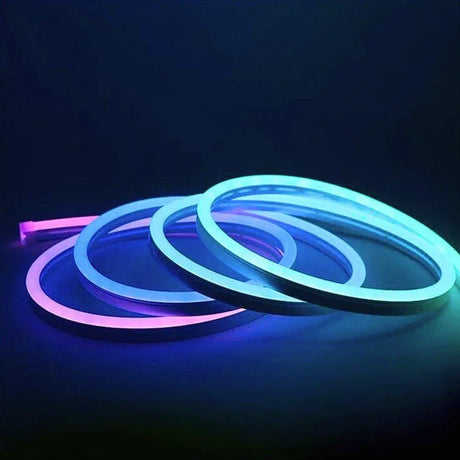

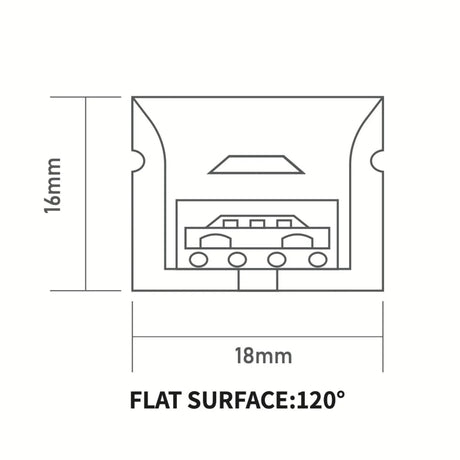

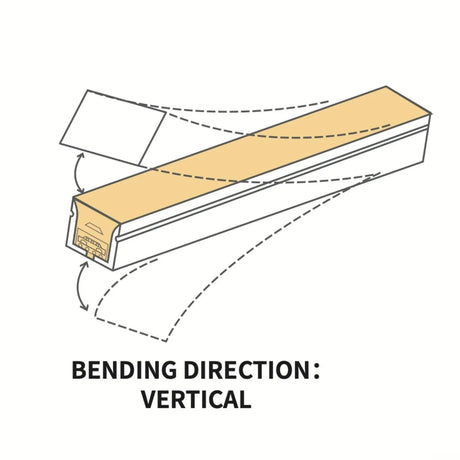

From £21.24Unit price /UnavailableUltra Long 18x16mm RGB Neon Flex 48V IP68 Top Bend Waterproof 30 Metre

From £44.50Unit price /UnavailableUltra Long Cool White LED Neon Flex 48V 10x20mm IP68 Waterproof 50m

From £24.52Unit price /UnavailableUltra Long Natural White Neon Flex 48V 10x20mm IP68 Waterproof 50m

From £24.52Unit price /UnavailableExtra Long Warm White Neon Flex 48V 10x20mm IP68 Waterproof 50m

From £24.52Unit price /UnavailableWarm White Neon Flex 2800K 24V 10x20mm IP67 Waterproof 20m

From £21.85Unit price /UnavailableWarm White Neon Flex 2800K 24V 10x20mm IP68 Waterproof 20m

From £24.52Unit price /UnavailableExtra Long Warm White Neon Flex 48V 10x20mm IP68 Waterproof 50m

From £24.52Unit price /UnavailableExtra Long 18x16mm Warm White 48V IP68 Top Bend Waterproof 30 Metre

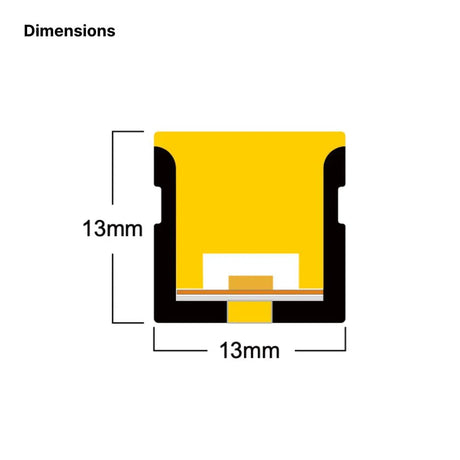

From £25.81Unit price /UnavailableRGBW (3000K) LED Neon Flex 13x13mm IP67 Waterproof 48V 20 Metre

From £21.95Unit price /UnavailableWarm White Neon Flex 2800K 48V 10x20mm IP67 Waterproof 50m

From £21.85Unit price /Unavailable

FAQ's

Best IP rating for neon flex in coastal environments

For coastal sites choose IP68 where possible and at minimum IP67 with marine-grade connectors and corrosion-resistant contacts to withstand salt spray and persistent moisture.

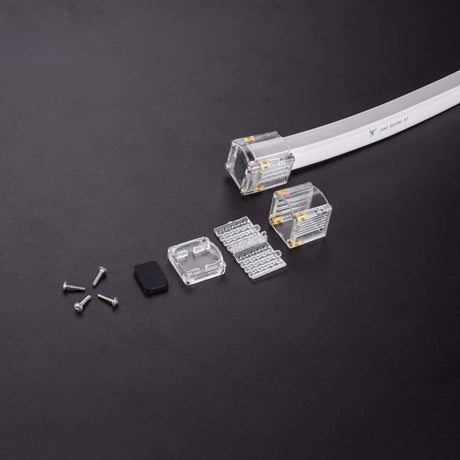

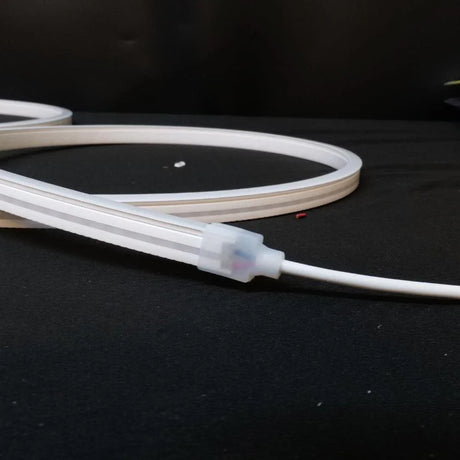

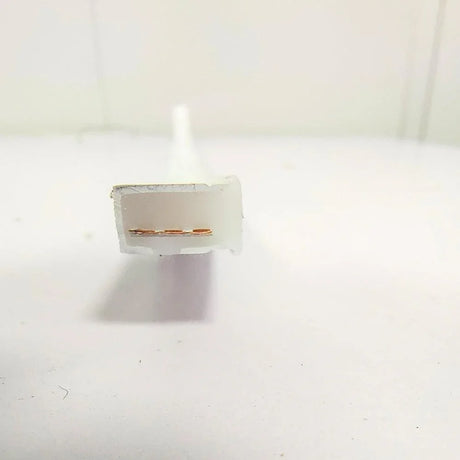

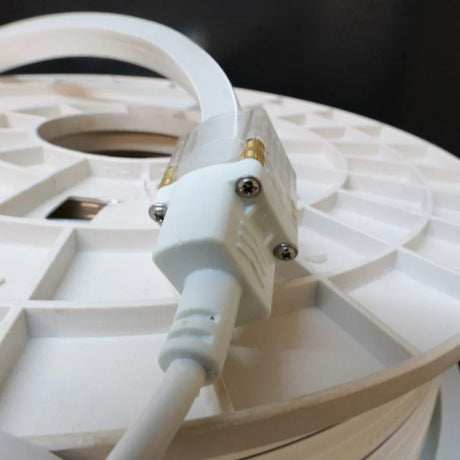

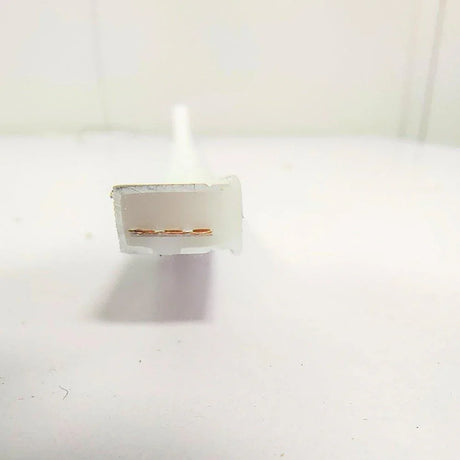

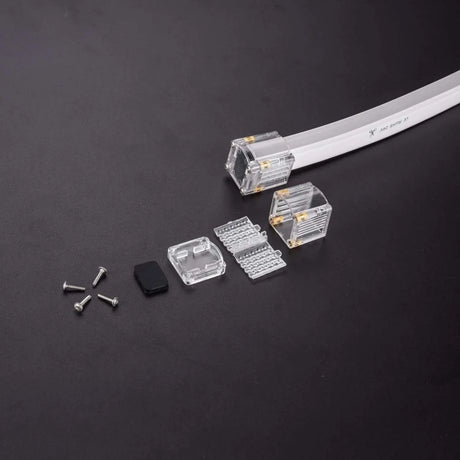

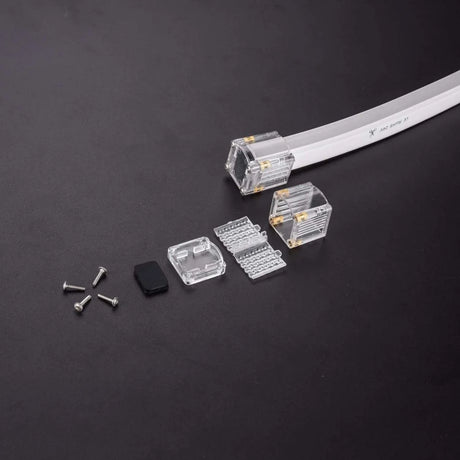

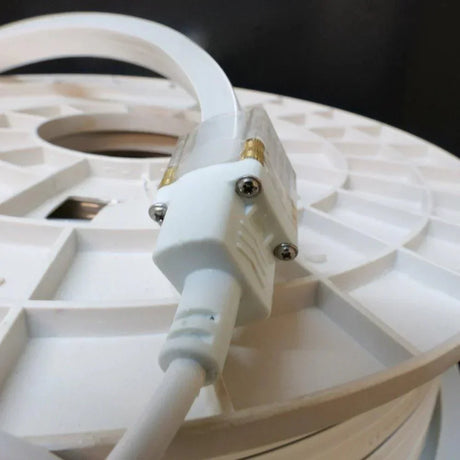

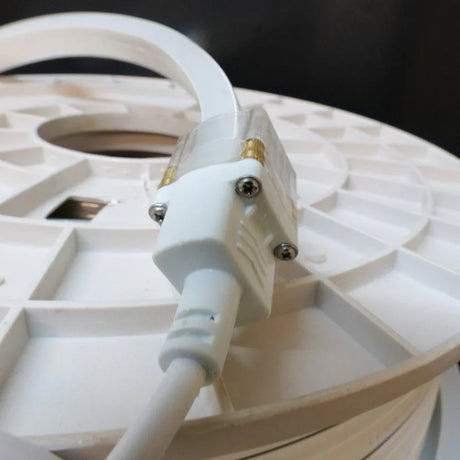

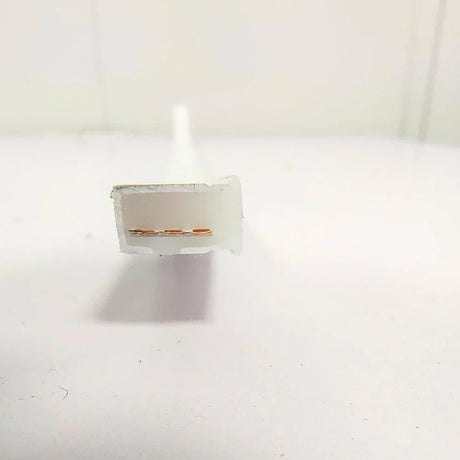

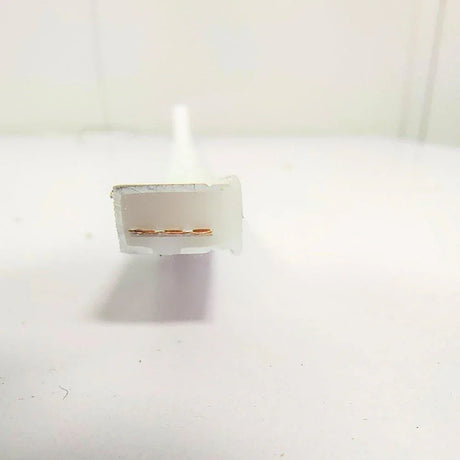

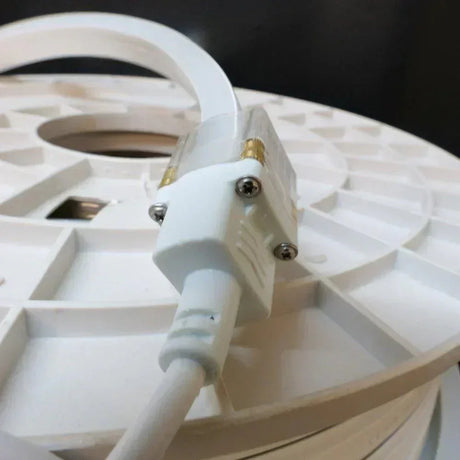

How to splice and waterproof neon flex joints

Use manufacturer-approved waterproof connectors or solder the joint, then encapsulate with adhesive-lined heatshrink, silicone potting or resin and test the seal for ingress protection before final installation.

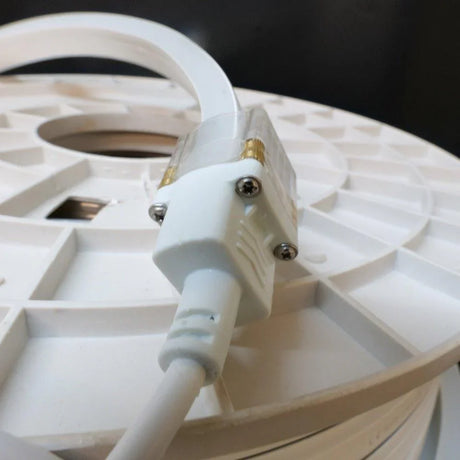

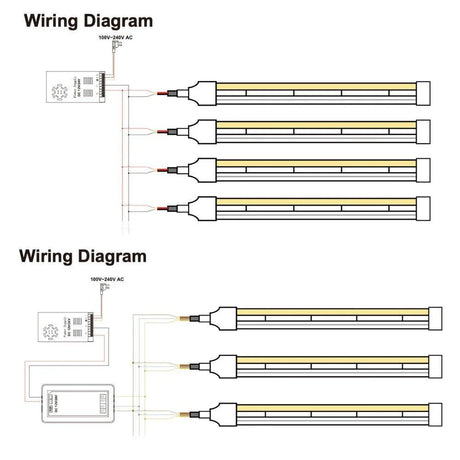

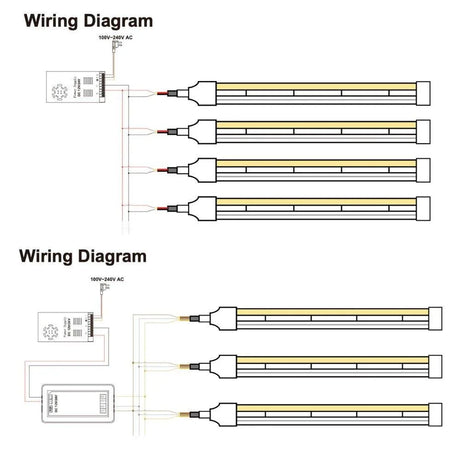

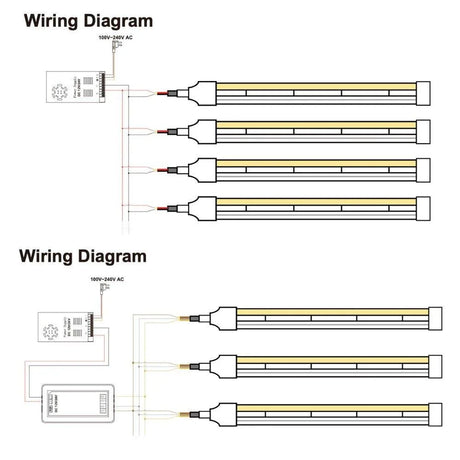

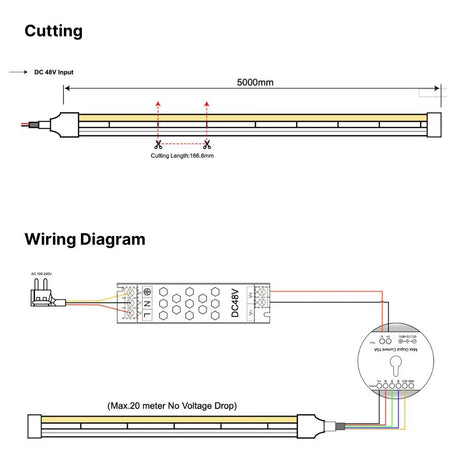

Maximum continuous run length for 48V neon flex

Many 48V products reliably run 30–50 m from a single feed for standard outputs, though you should always check the product datasheet and plan centre-feeds or injections for very long or high-output runs.

Recommended power supply wattage per metre for neon flex

Wattage varies by product (commonly ~8–20 W/m); size the supply by multiplying W/m × length and add 20–30% headroom to allow for inrush and continuous loading.

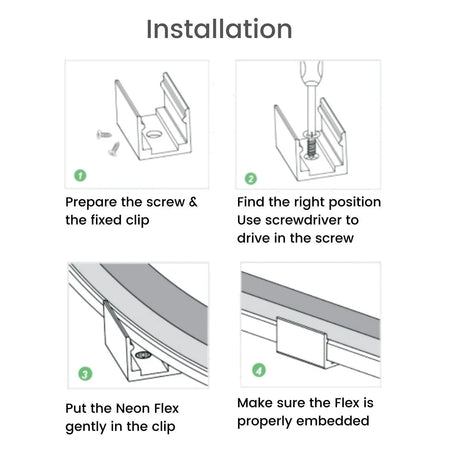

Installation tips for mounting neon flex on signage frames

Mount in aluminium channels or stainless clips for straight runs, allow expansion gaps, route cables inside sealed cavities, and avoid sharp fixings that pinch the jacket — test the finish before permanently sealing.

What IP rating (IP65 vs IP67 vs IP68) is best for gardens, façades, and pools?

Use IP65 for sheltered garden accents, IP67 for exposed façades and wash-down areas, and IP68 (with appropriate depth rating) for pools and permanently submerged features.

How does outdoor LED Neon Flex differ from indoor versions (materials, UV, sealing)?

Outdoor neon flex uses UV-stabilised silicone or thicker jackets, corrosion-resistant connectors, and fully potting/sealed terminations compared with thinner indoor jackets and lighter sealing methods.

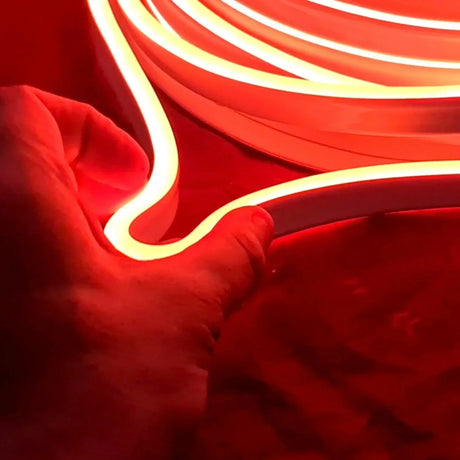

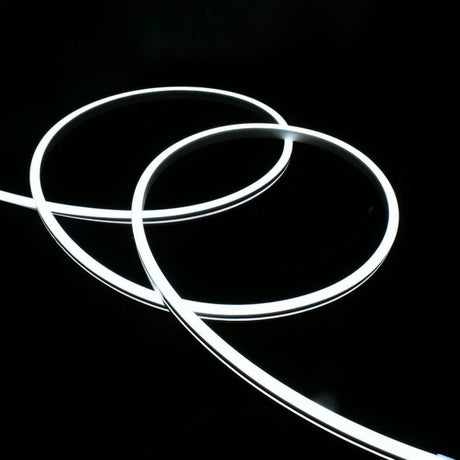

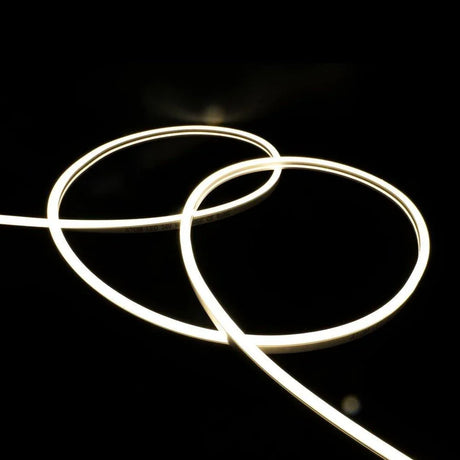

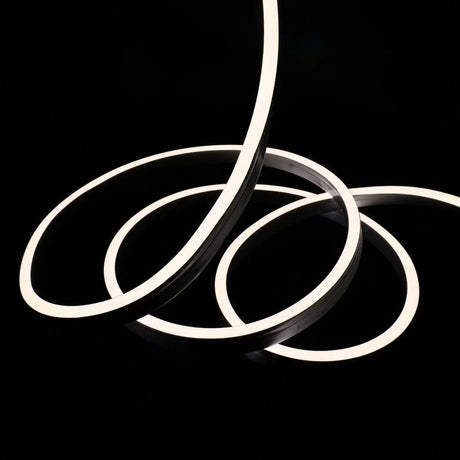

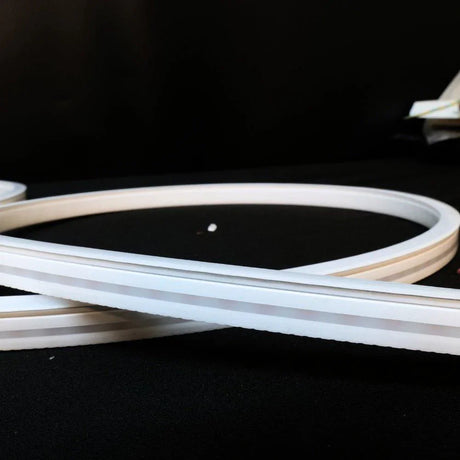

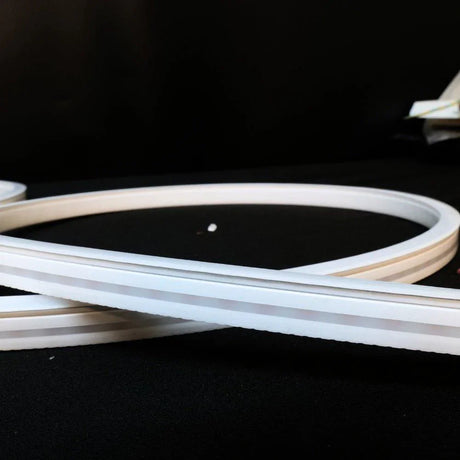

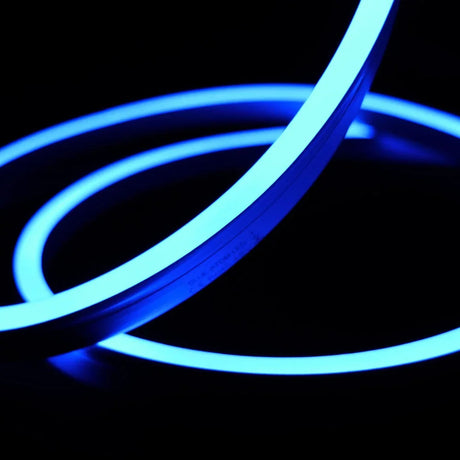

Pros and cons of outdoor LED Neon Flex vs outdoor LED strips in aluminium profiles

Neon flex gives continuous, dot-free lines and easier weatherproofing, while strips in aluminium profiles often offer higher raw lumens and superior heat dissipation but can show LED points and need deeper channels for sealing.

How should ends, joins, and power feeds be sealed to maintain IP67/IP68 in UK weather?

Always use manufacturer end-caps, adhesive-lined heatshrink or resin potting, IP-rated glands for cable entries, and mount power supplies/controllers inside weatherproof enclosures with proper ventilation and RCD protection.

Best practices for routing cables, placing drivers, and junction boxes outdoors

Route cables in conduit or trunking, locate drivers in ventilated IP-rated enclosures above potential water levels, use IP67 junction boxes and strain relief, and ensure mains circuits are RCD-protected and accessible for maintenance.

How do mounting methods affect drainage, thermal performance, and lifespan outdoors?

Aluminium channels improve heat dissipation and protect the flex, clips allow drainage but less cooling, and buried installs must include drainage and protective conduits to avoid standing water and overheating that shorten life.

How can outdoor LED Neon Flex safely highlight garden paths, steps, and decking edges?

Recess flex into edge channels or steps with diffusers and non-slip covers, use warm white or low-glare options, and ensure low-voltage supplies or adequately protected mains circuits for safety near foot traffic.

Effective ways to use outdoor neon flex on façades and shopfronts

Run continuous outlines around architectural features, backlight signage panels, or create halo effects with concealed channels and warm/brand colours for strong after-dark visibility and brand impact.

Is outdoor neon flex suitable for pools, fountains, and coastal locations, and what extra precautions are needed?

Yes when rated IP68 and installed with fully potted joints, salt-resistant connectors, elevated/isolated transformers, and routine inspection; avoid direct mains terminations in wet zones and follow local electrical codes for water installations.

How do UV, temperature swings, and moisture affect long-term performance?

UV causes yellowing and embrittlement in low-quality jackets, temperature cycling stresses seals, and chronic moisture can corrode contacts — specify UV-stabilised silicone, proven seals, and corrosion-resistant hardware to mitigate these effects.

Recommended cleaning and inspection routines to keep outdoor neon flex bright and watertight

Clean annually (or more in coastal/industrial areas) with mild detergent and soft cloth, inspect seals and glands for cracking or corrosion, and reseal or replace suspect joints immediately.

How does power consumption and lifespan compare with bollards and spotlights?

Neon flex typically uses lower power per linear metre and offers long lifespans (commonly 30k–50k hours), but it produces linear ambient light rather than the focused beam of bollards/spotlights, so choose by application and lumen distribution needs.

What should buyers check when selecting outdoor neon flex?

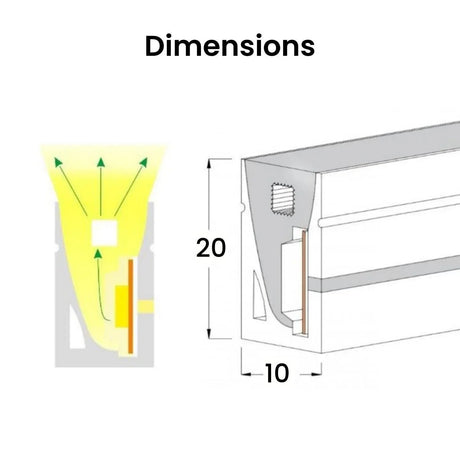

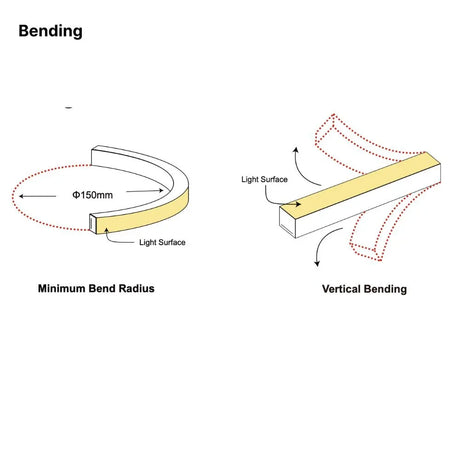

Verify IP rating, UV/salt-air resistance, lumen/m, CRI, cut-intervals and bend radius, recommended mounting/profile options, warranty terms, and whether supplier provides marine-grade connectors if needed.

How do UK suppliers position their outdoor neon flex ranges for gardens vs commercial façades?

Retail ranges target homeowners with pre-cut kits, plug-and-play drivers and lower IP ratings, while trade/commercial ranges offer higher IP/UV specs, custom lengths, stainless fittings and project support for façades and signage.