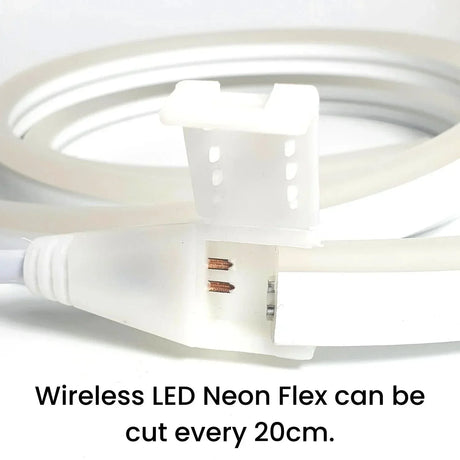

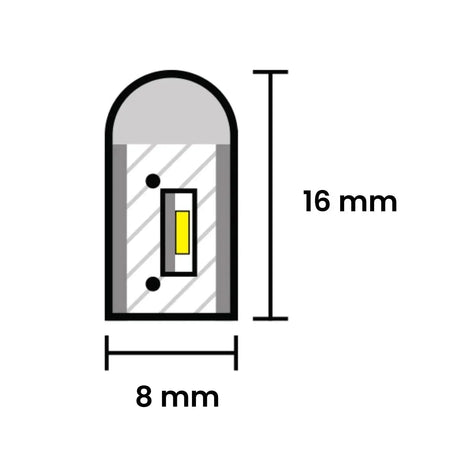

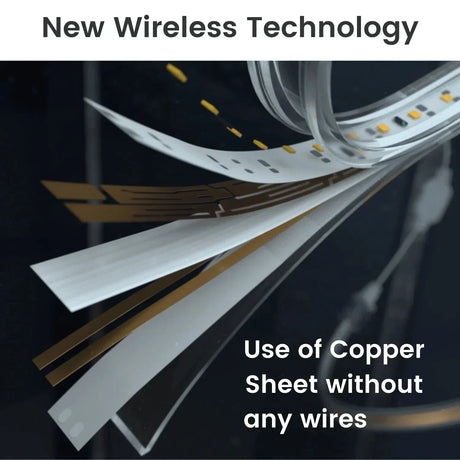

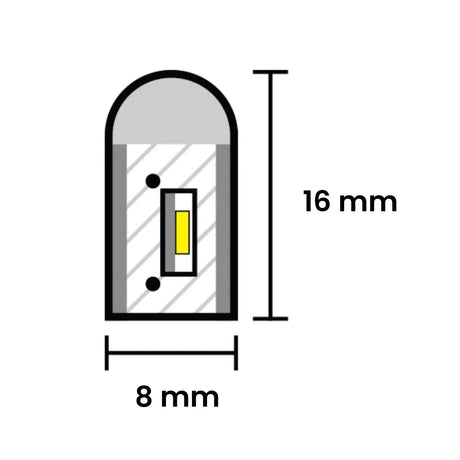

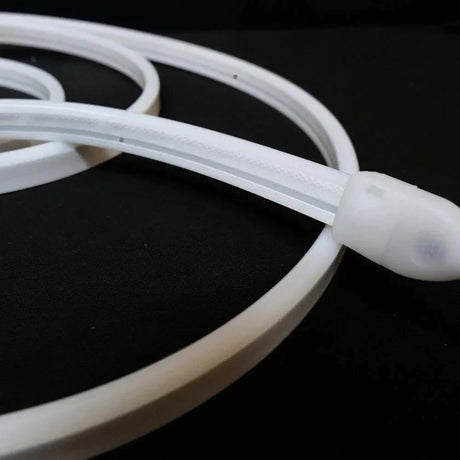

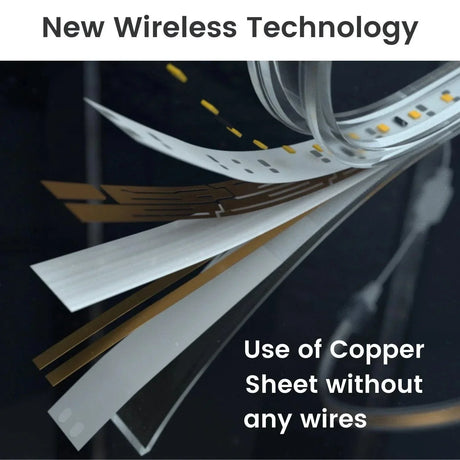

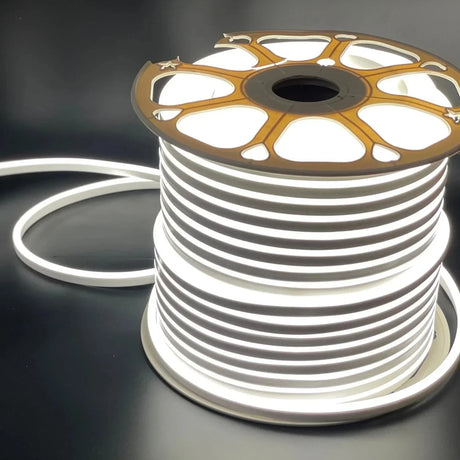

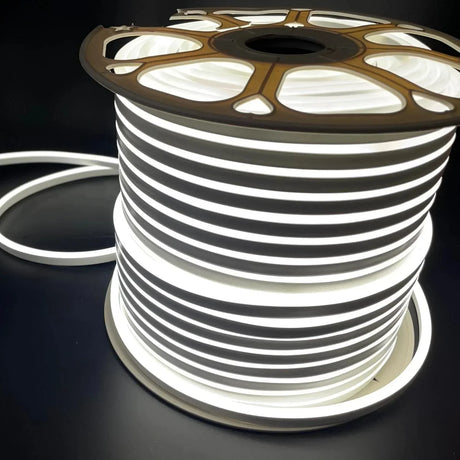

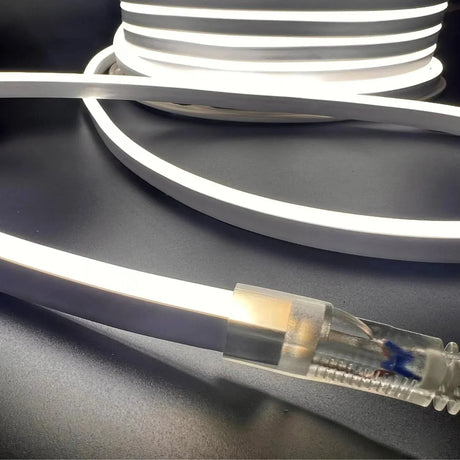

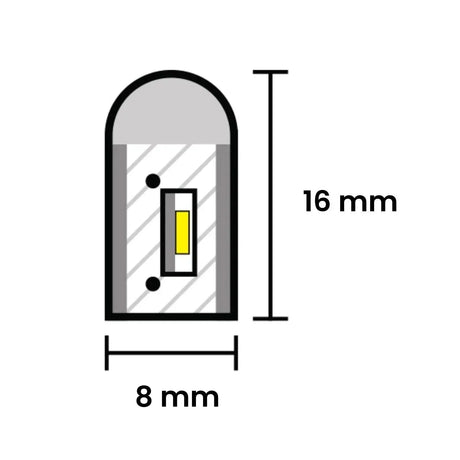

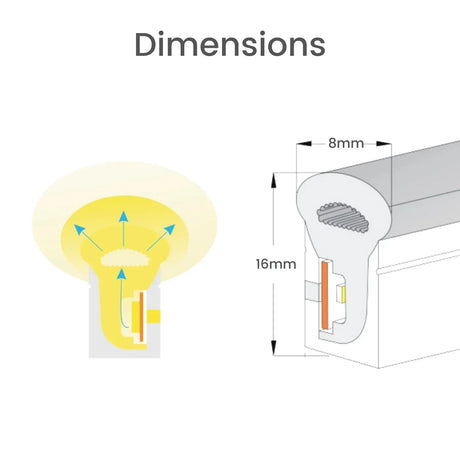

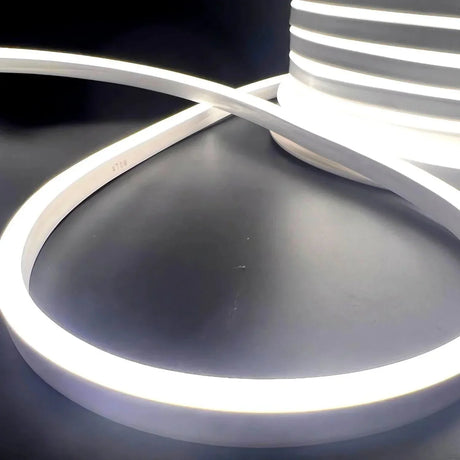

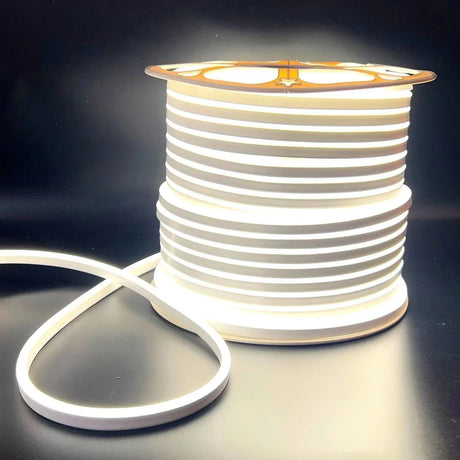

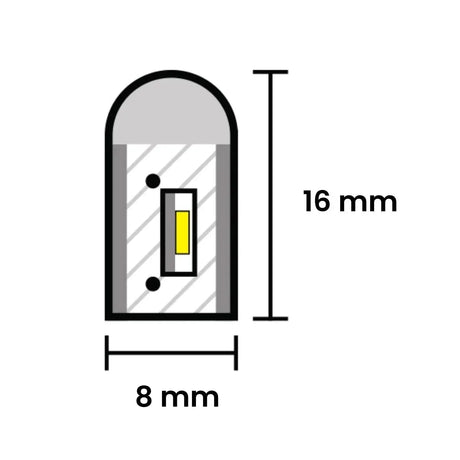

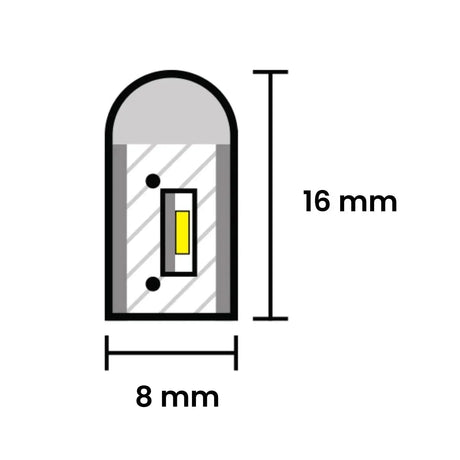

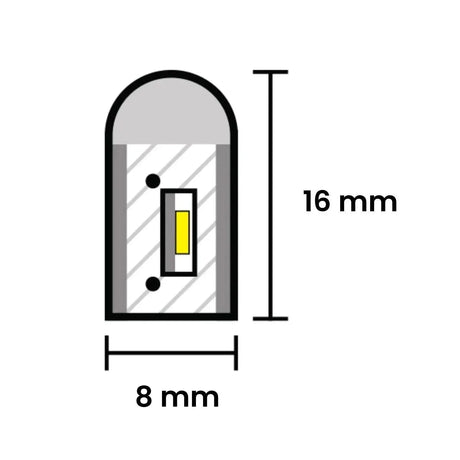

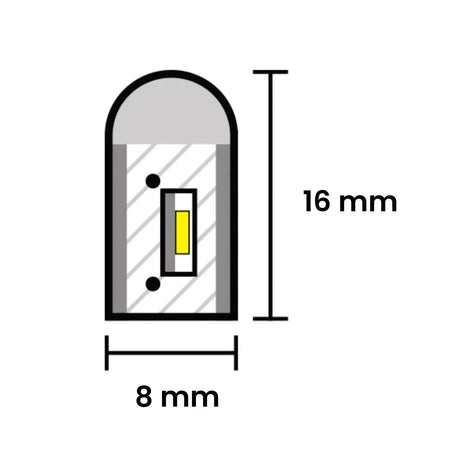

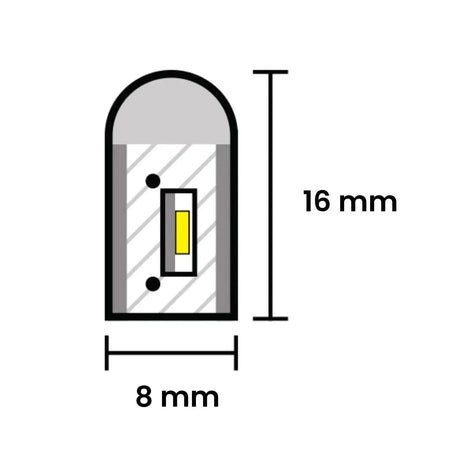

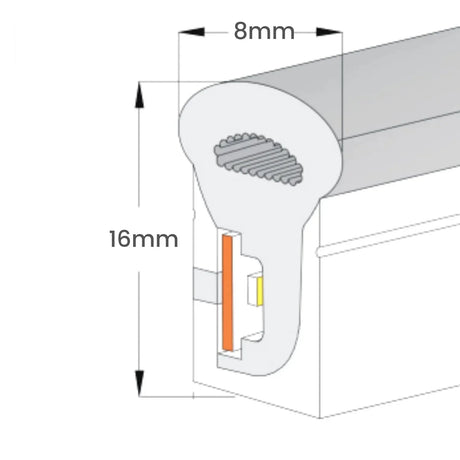

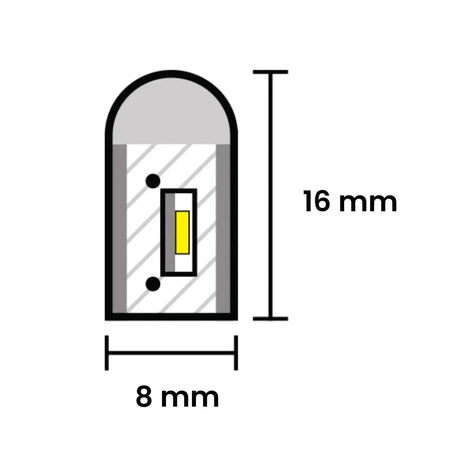

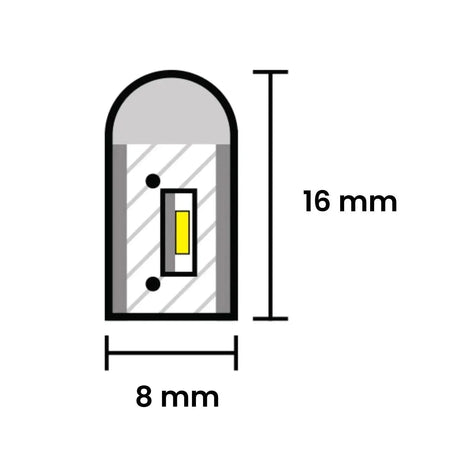

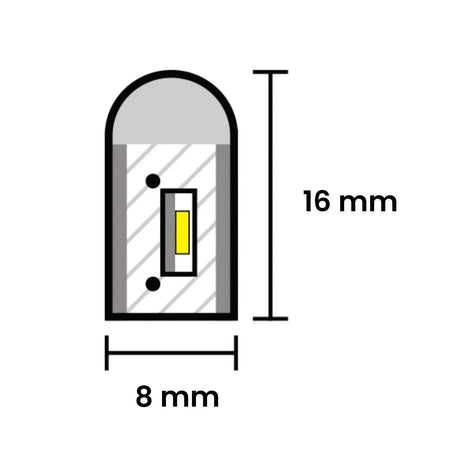

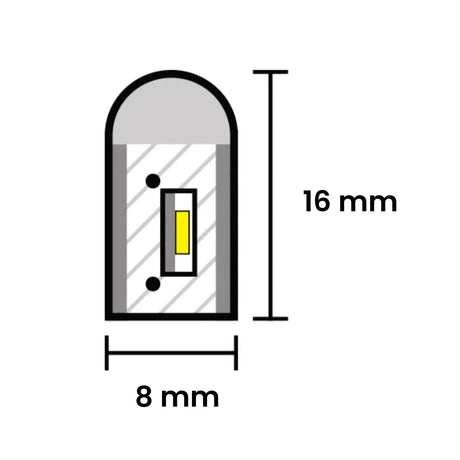

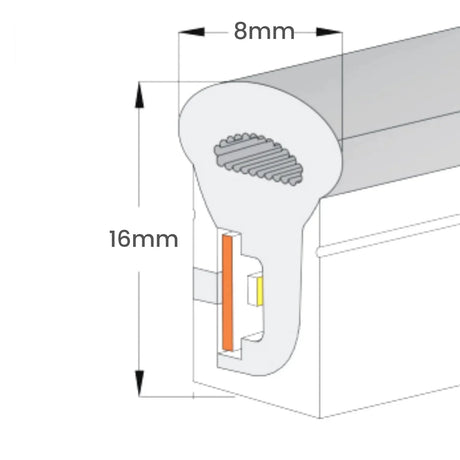

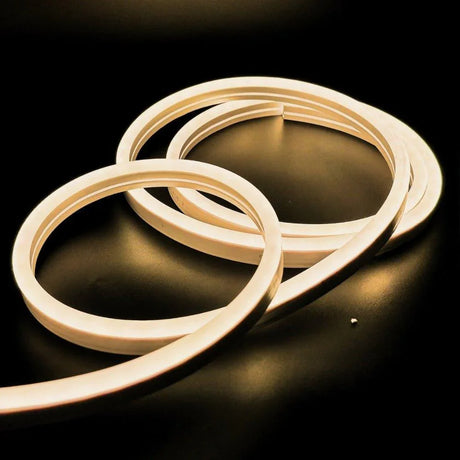

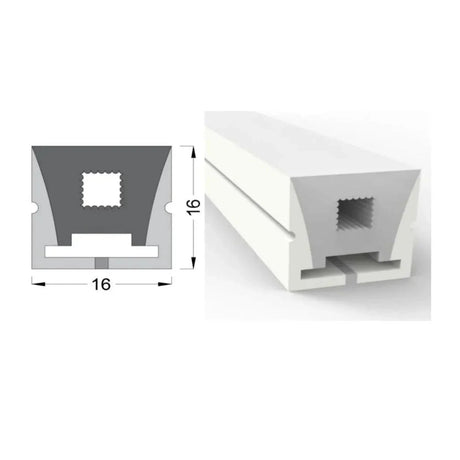

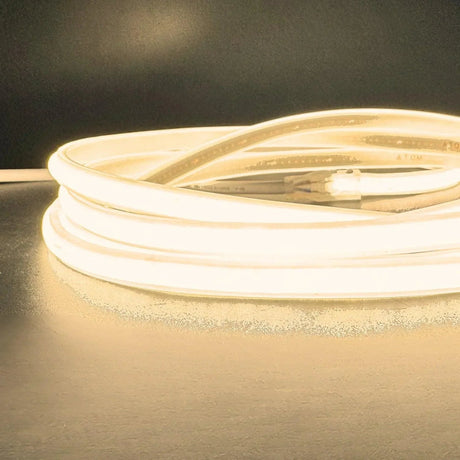

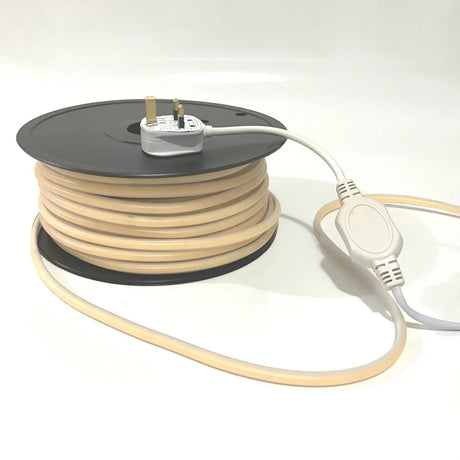

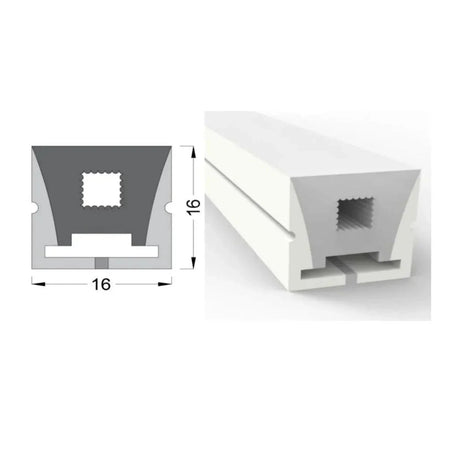

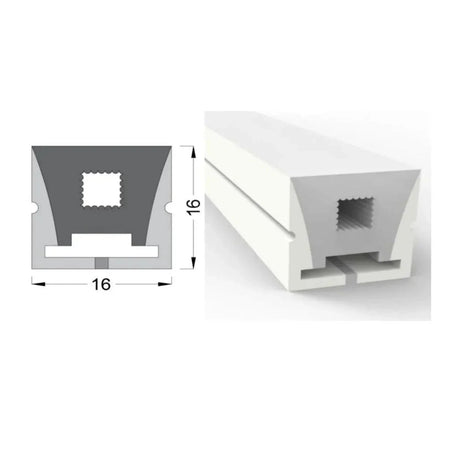

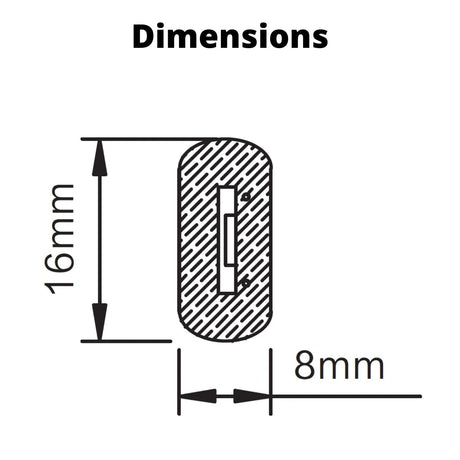

Warm White LED Neon Flex 220V 240V Wireless 8x16mm 120LEDs/m IP65 with UK Plug

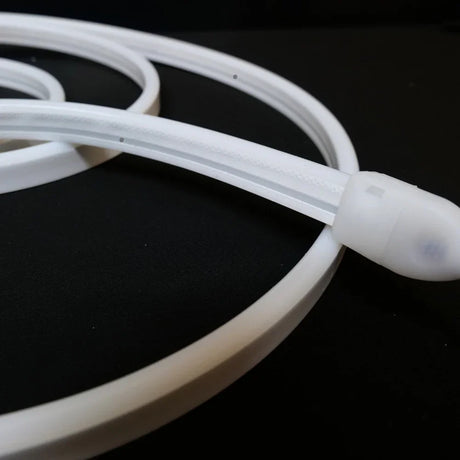

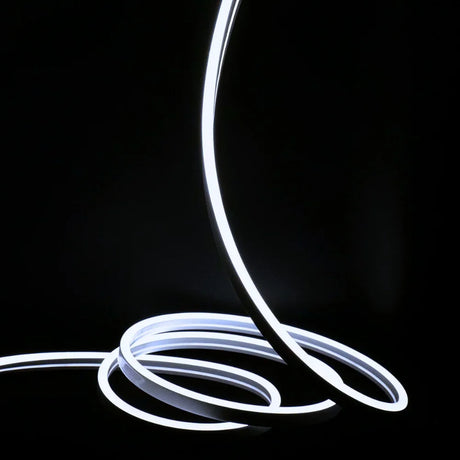

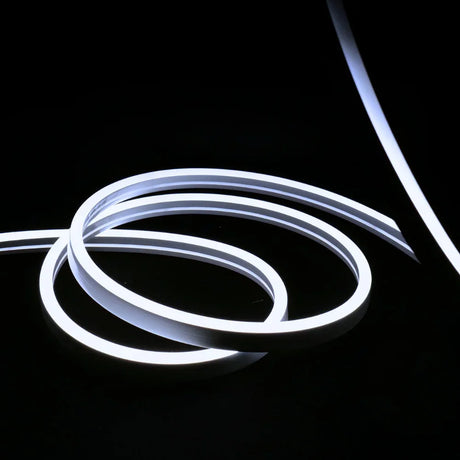

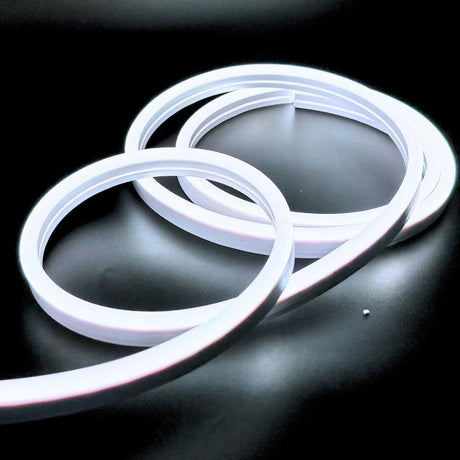

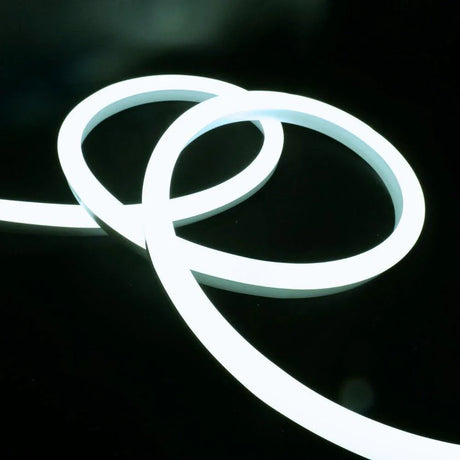

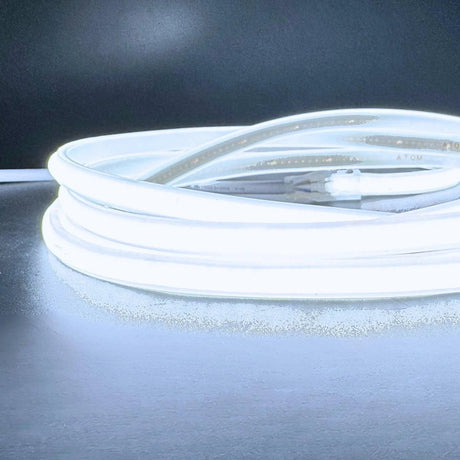

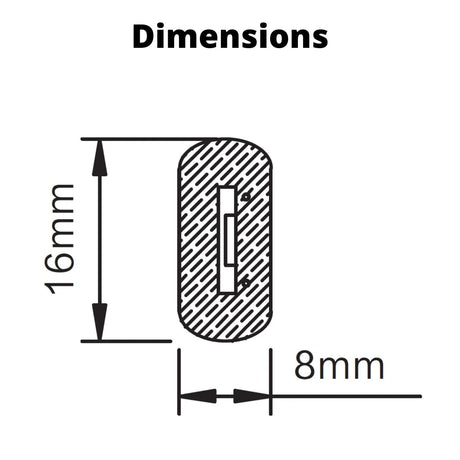

From £18.66Unit price /UnavailableCool White LED Neon Flex Wireless 8x16mm 120LEDs/m 220V 240V IP65 Waterproof with UK Plug

From £18.66Unit price /UnavailableNatural White Neon Flex 220V 240V Wireless 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

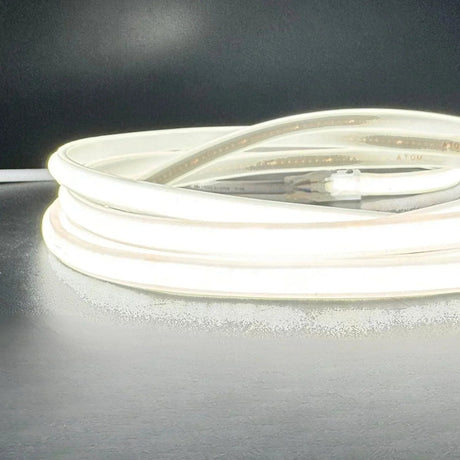

From £17.91Unit price /UnavailableWarm White LED Neon Flex AC 220V 240V 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

From £13.95Unit price /UnavailableNatural White Neon Flex 220V 240V 8x16mm 120LEDs/m 4000K IP65 Waterproof with UK Plug

From £13.95Unit price /UnavailableCool White Neon Flex 220V 240V 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

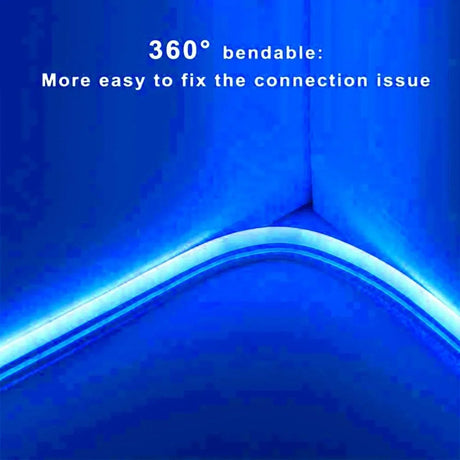

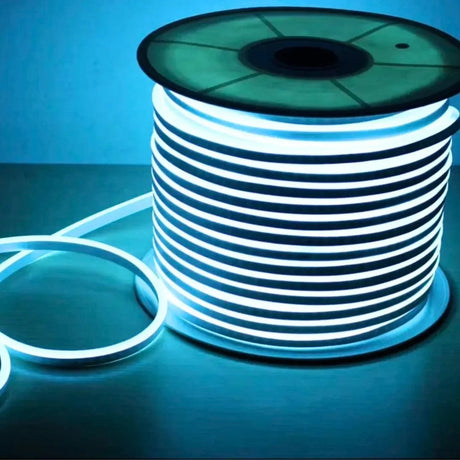

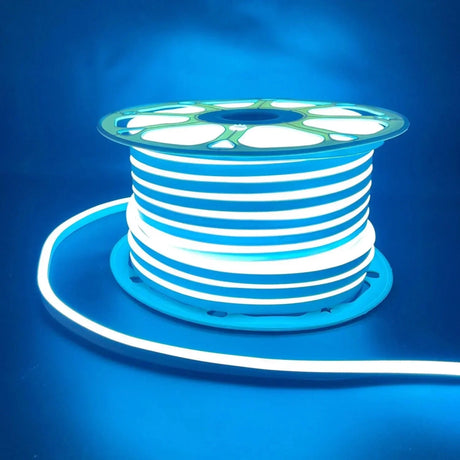

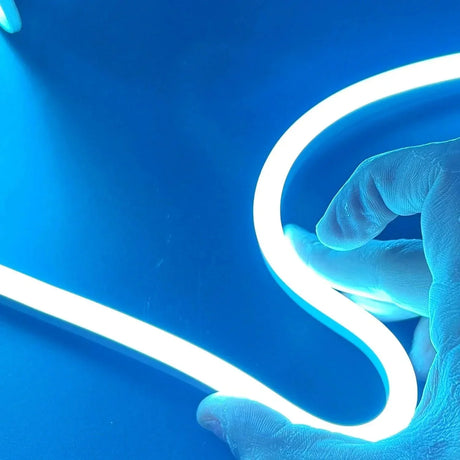

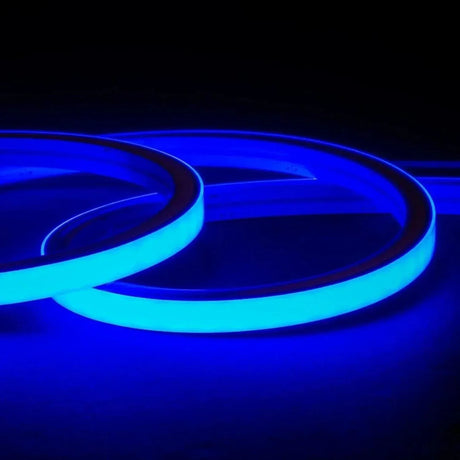

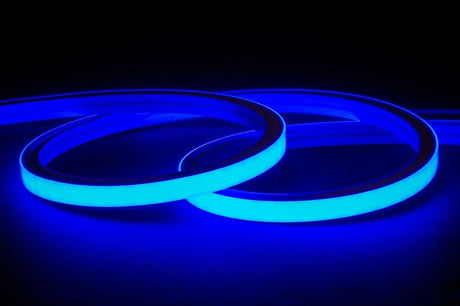

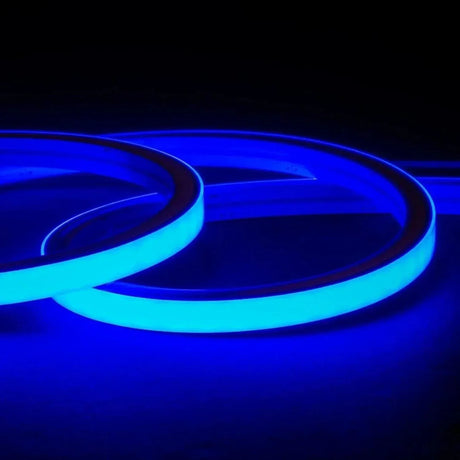

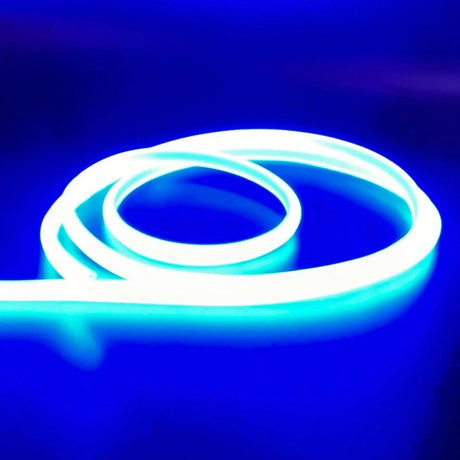

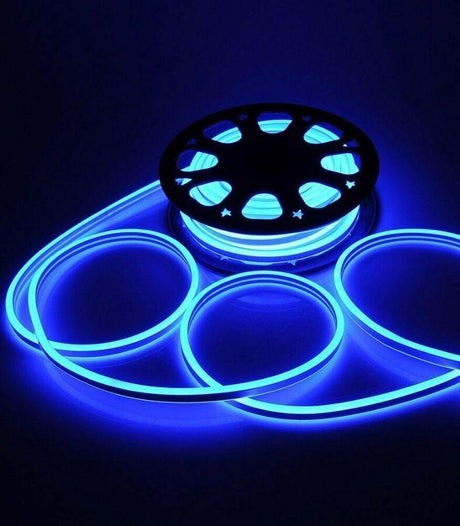

From £13.95Unit price /UnavailableBlue LED Neon Flex 8x16mm 120LEDs/m AC 220 240V IP65 Waterproof with UK Plug

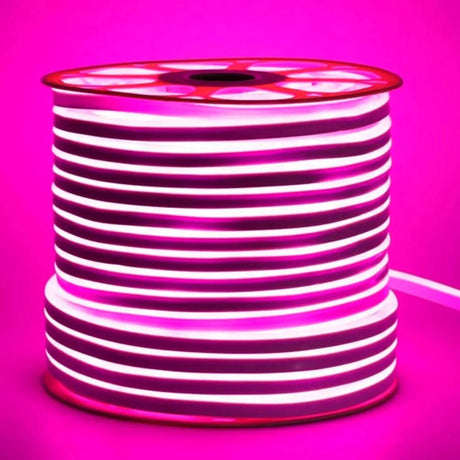

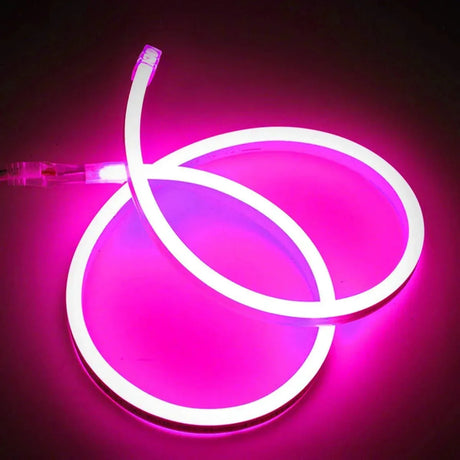

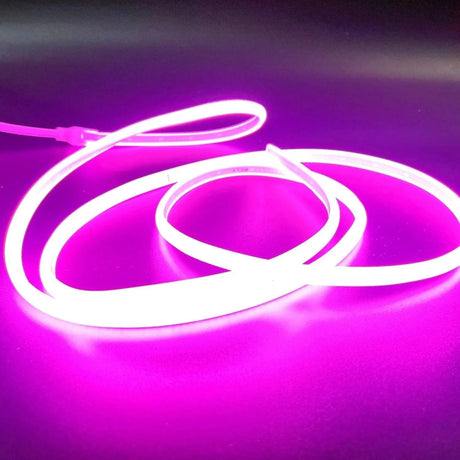

From £13.95Unit price /UnavailablePink LED Neon Flex 220V 240V 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

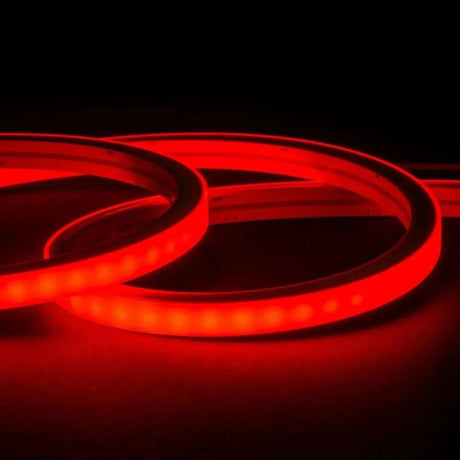

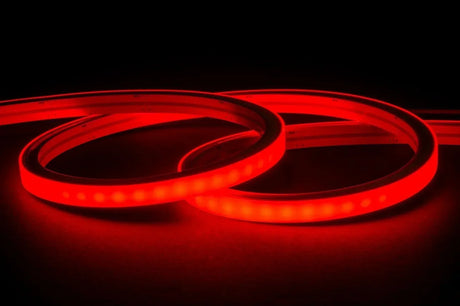

From £13.95Unit price /UnavailableRed LED Neon Flex 220V 240V 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

From £13.95Unit price /UnavailableGolden Neon Flex 220V 240V 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

From £13.95Unit price /UnavailableIce Blue Neon Flex 220V 240V 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

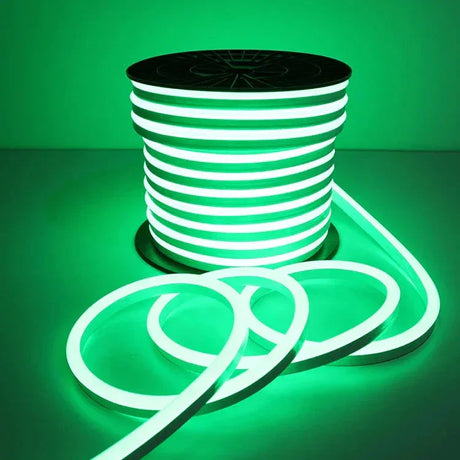

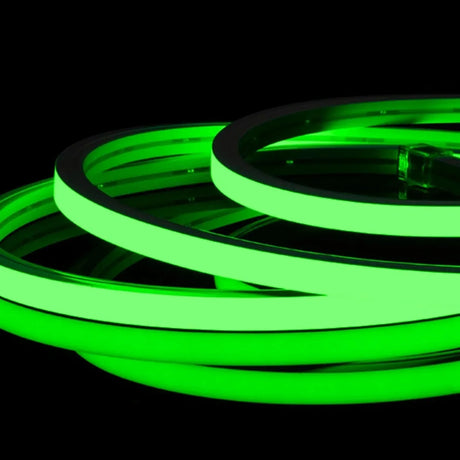

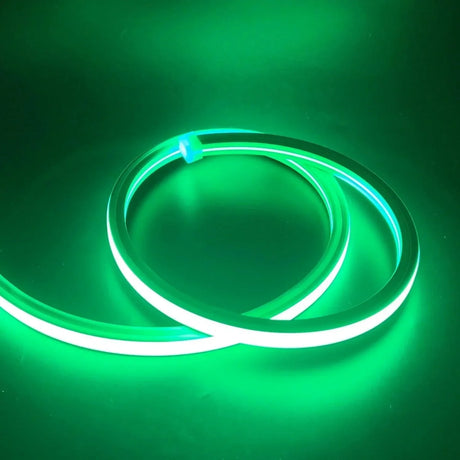

From £13.95Unit price /UnavailableGreen LED Neon Flex 220V 240V 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

From £13.95Unit price /UnavailablePurple Neon Flex 220V 240V 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

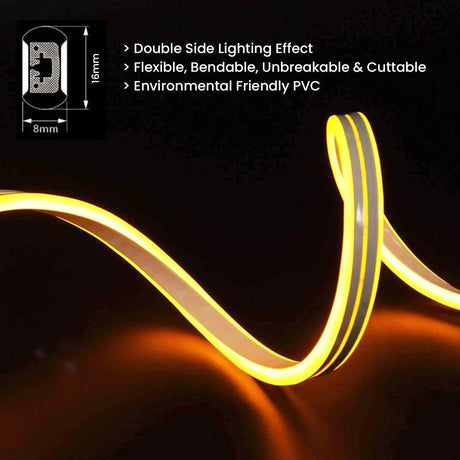

From £13.95Unit price /UnavailableYellow LED Neon Flex 220V 240V 8x16mm 120LEDs/m IP65 Waterproof with UK Plug

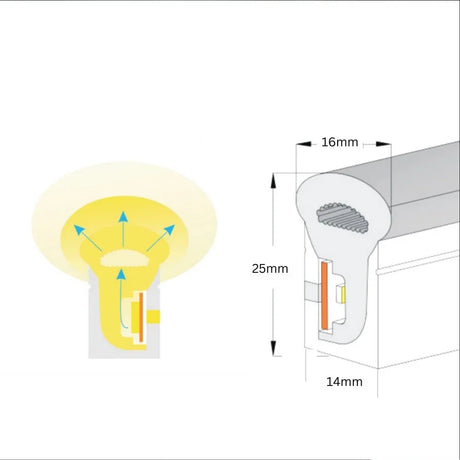

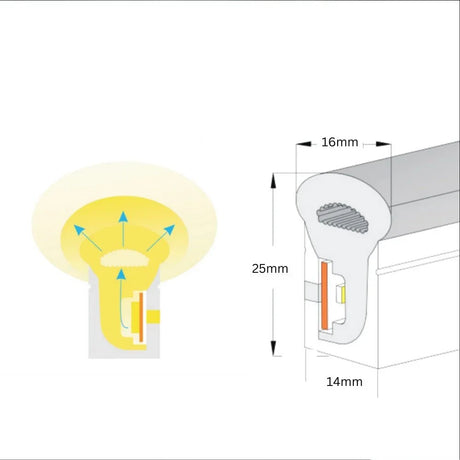

From £13.95Unit price /UnavailableWarm White Neon Flex 14x25mm 220V 240V 120LEDs/m IP65 Waterproof with UK Plug

From £17.85Unit price /UnavailableCool White Neon Flex 14x25mm 220V 240V 120LEDs/m IP65 Waterproof with UK Plug

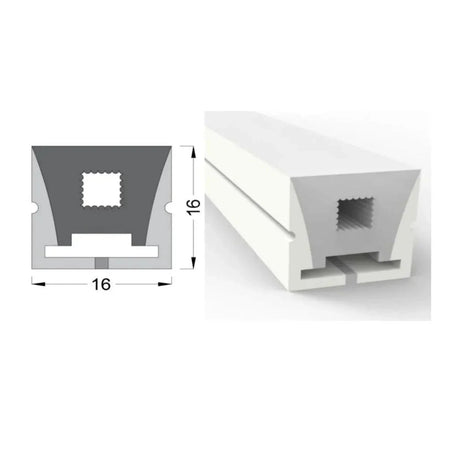

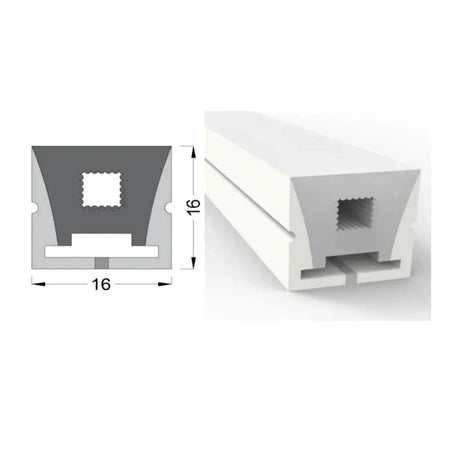

From £17.85Unit price /UnavailableWarm White LED Neon Flex 220V 240V 16x16mm D Shape Top Bend 120LEDs/m IP65 with UK Plug

From £17.54£19.85Unit price /UnavailableNatural White Neon Flex 16x16mm D Shape Top Bend 120LEDs/m 220V 240V IP65 with UK Plug

From £17.54£19.85Unit price /UnavailableCool White Neon Flex 16x16mm D Shape Top Bend 120LEDs/m 220V 240V IP65 with UK Plug

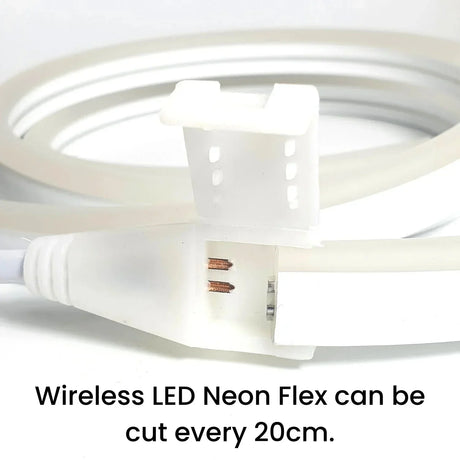

From £17.54£19.85Unit price /UnavailableWarm White Neon Flex 3000K 16x16mm 220V 240V Top Bend 20cm Cut IP65 Waterproof with UK Plug

From £17.95Unit price /UnavailableNatural White LED Neon Flex 4000K 220V 240V 220V 240V Top Bend 20cm Cut IP65 with UK Plug

From £17.95Unit price /UnavailableCool White LED Neon Flex 6000K 16x16mm 220V 240V Top Bend 20cm Cut IP65 with UK Plug

From £17.95Unit price /UnavailableBlue LED Neon Flex 16x16mm 220V 240V Top Bending 120LEDs/m 20cm Cut IP65 Waterproof with UK Plug

From £17.95Unit price /UnavailableGreen LED Neon Flex 220V 240V Flat Shape Top Bend 20cm Cut IP65 with UK Plug

From £17.95Unit price /UnavailableRed LED Neon Flex 220V 240V Top Bend 20cm Cutting IP65 with UK Plug

From £17.95Unit price /UnavailableYellow LED Neon Flex 220V 240V Top Bend 20cm Cut IP65 with UK Plug

From £17.95Unit price /UnavailablePink LED Neon Flex 220V 240V Top Bend 20cm Cut IP65 with UK Plug

From £17.95Unit price /UnavailableOrange LED Neon Flex 220V 240V Top Bend 20cm Cut IP65 with UK Plug

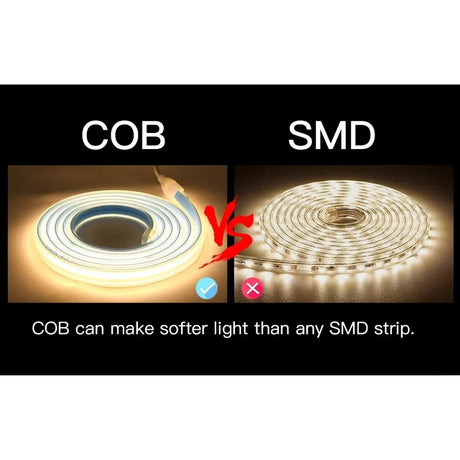

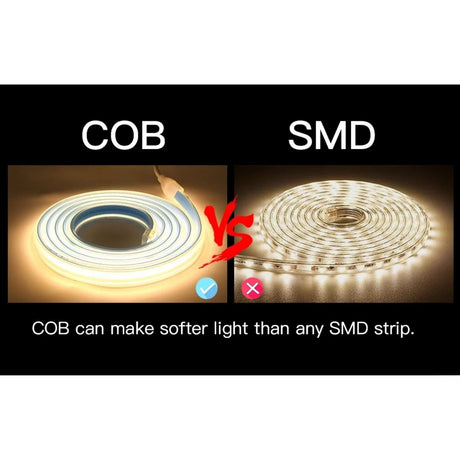

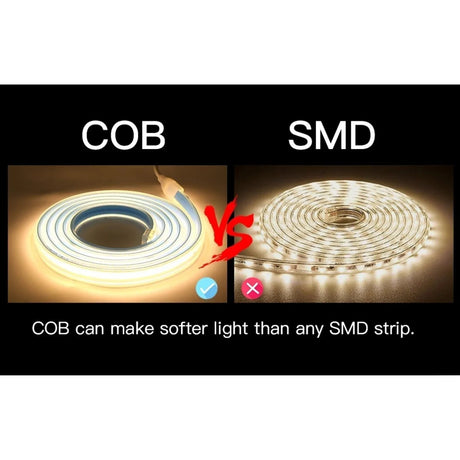

From £17.95Unit price /UnavailableCool White 6000K COB LED Strip 220V 240V 288 LEDs/m IP65 UK Plug

From £16.95Unit price /UnavailableNatural White 4000K COB LED Strip 220V 240V 288 LEDs/m IP65 UK Plug

From £16.95Unit price /UnavailableWarm White 3000K COB LED Strip 220V 240V 288 LEDs/m IP65 UK Plug

From £16.95Unit price /UnavailableBlue COB LED Strip Light 220V 240V 288 LEDs/m IP65 with UK Plug

From £16.95Unit price /UnavailablePink COB LED Strip Light 220V 240V 288 LEDs/m IP65 with UK Plug

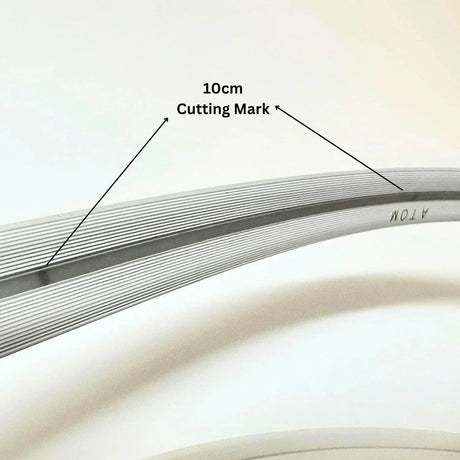

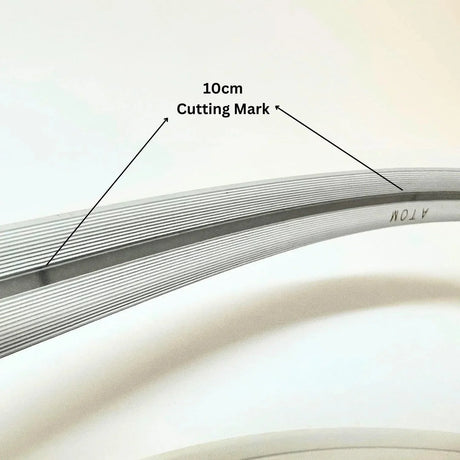

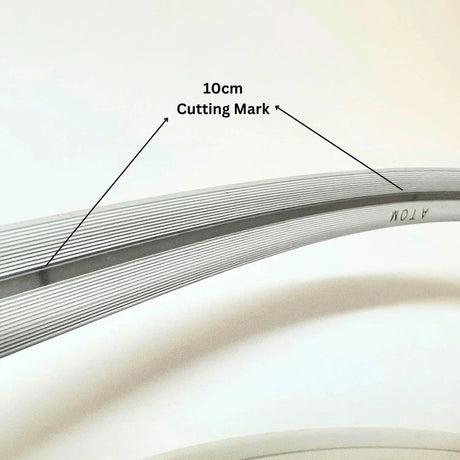

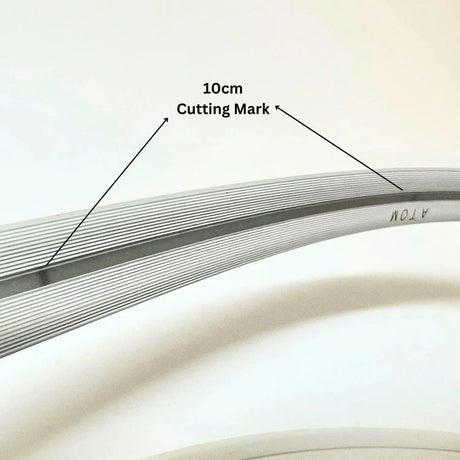

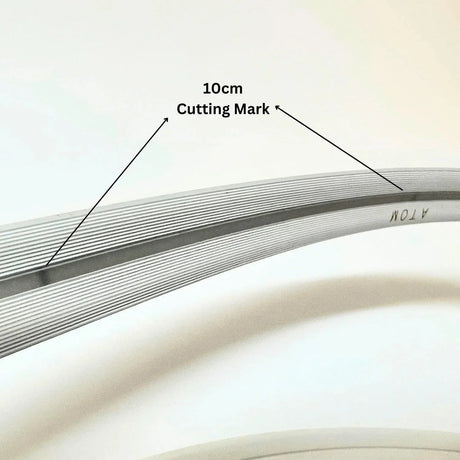

From £16.95Unit price /UnavailableWarm White Neon Flex 3000K 16x16mm 220V 240V Top Bend IP65 10cm Cut with UK Plug

From £18.95Unit price /UnavailableNatural White Neon Flex 4000K 16x16mm 220V 240V Top Bend IP65 10cm Cut with UK Plug

From £18.95Unit price /UnavailableCool White Neon Flex 6000K 16x16mm 220V 240V Top Bend IP65 10cm Cut with UK Plug

From £18.95Unit price /UnavailableCool White Neon Flex Double Side 220V 240V 120LED/m 8x16mm IP67 Waterproof Full Kit

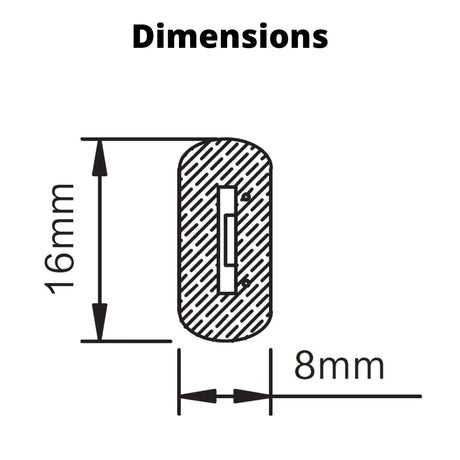

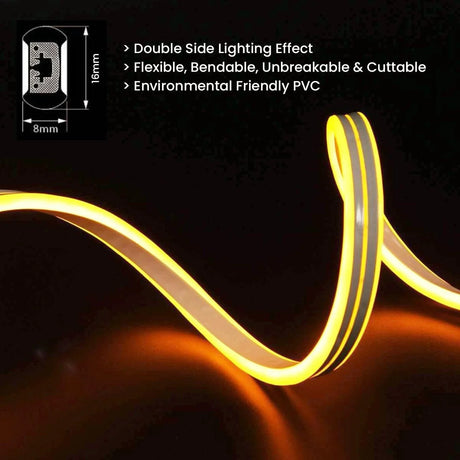

From £14.95Unit price /UnavailableBlue Neon Flex Double Side 220V 240V 120LED/m 8x16mm IP67 Waterproof Full Kit

From £14.95Unit price /UnavailableWarm White LED Neon Flex Double Side 220V 240V 120LED/m 8x16mm IP67 Waterproof Full Kit

From £14.95Unit price /Unavailable

FAQ's

Compare 230V neon flex IP67 versus IP65 for outdoor use

IP67-rated 230V neon flex is sealed against temporary immersion and offers better protection at joints and low points, while IP65 only protects against water jets and is better for sheltered or splash-prone locations choose IP67 where standing water or heavy wash-down is possible.

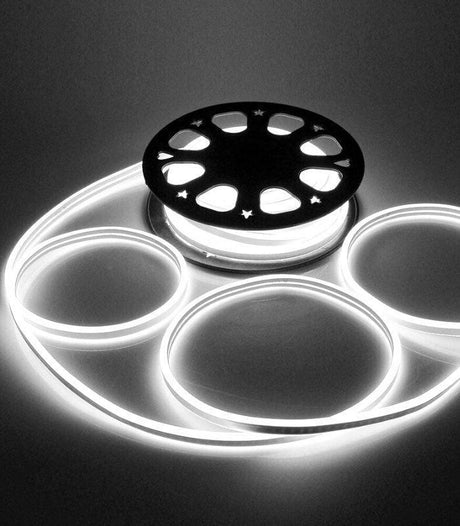

Max continuous run length for 230V single colour neon flex

Many 230V neon flex products support long continuous runs (often 50–100+ metres) from a single feed, but the exact maximum depends on the manufacturer’s spec and allowable voltage/current along the internal conductor; always check the product data sheet.

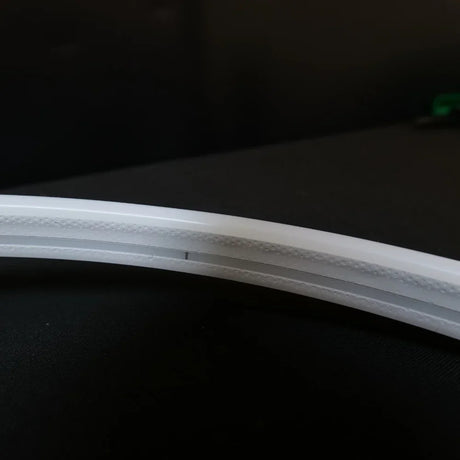

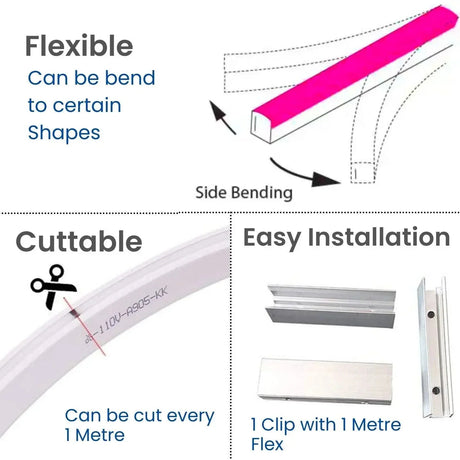

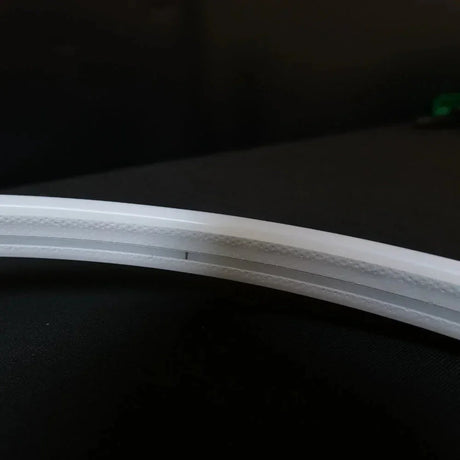

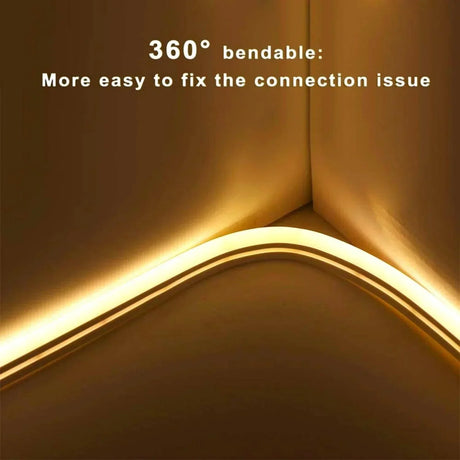

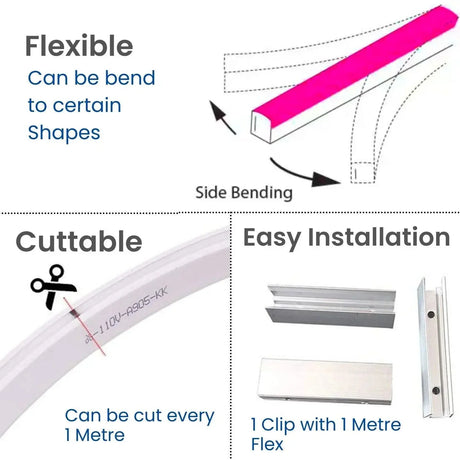

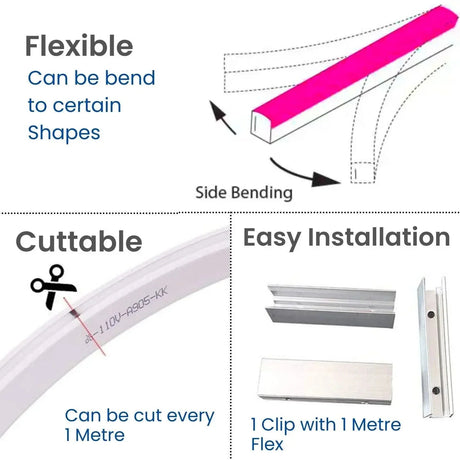

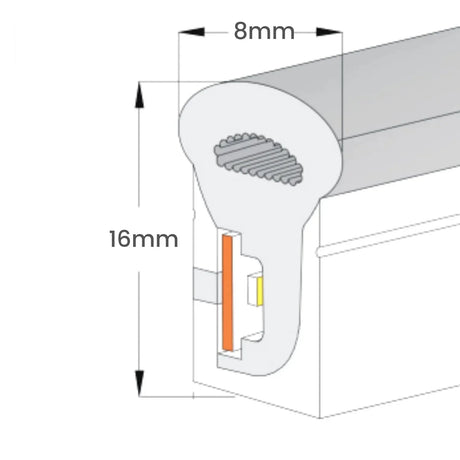

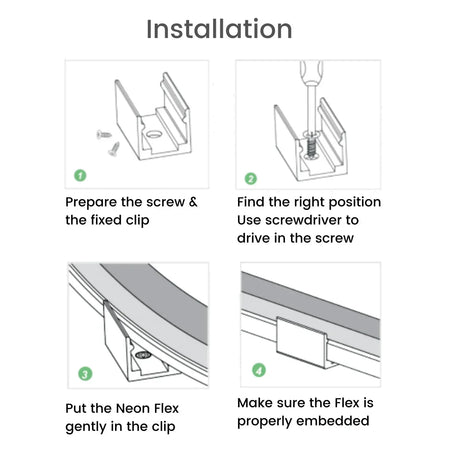

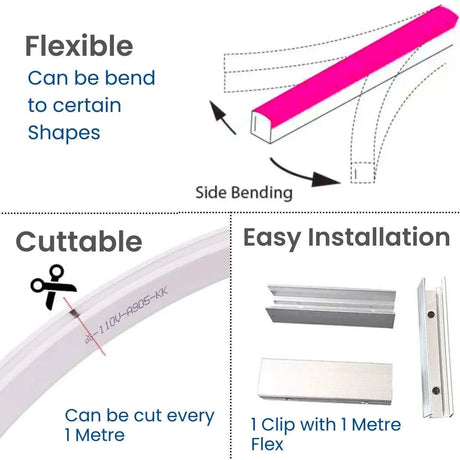

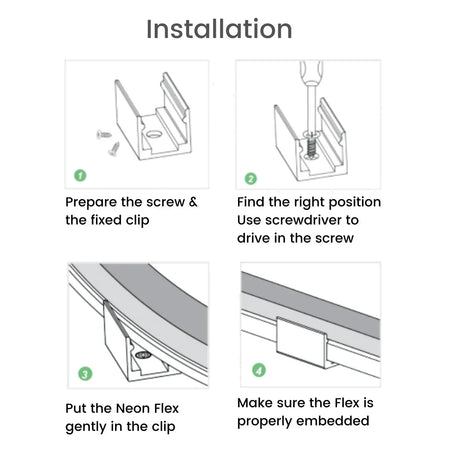

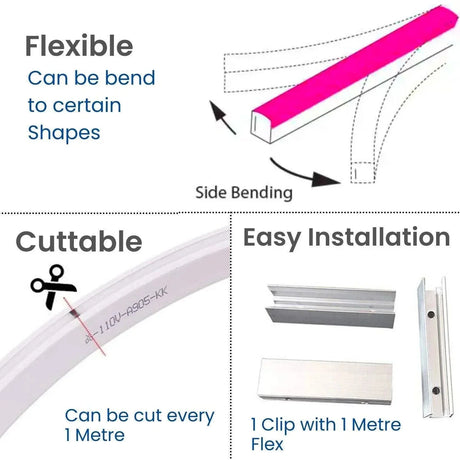

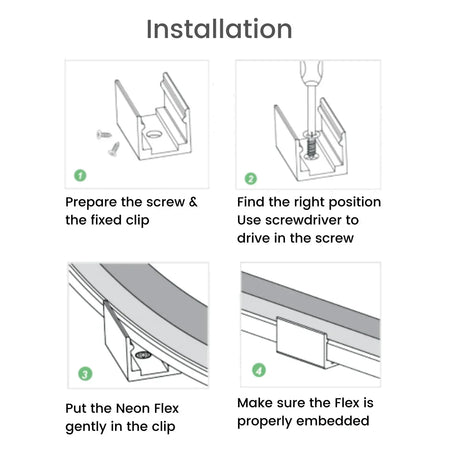

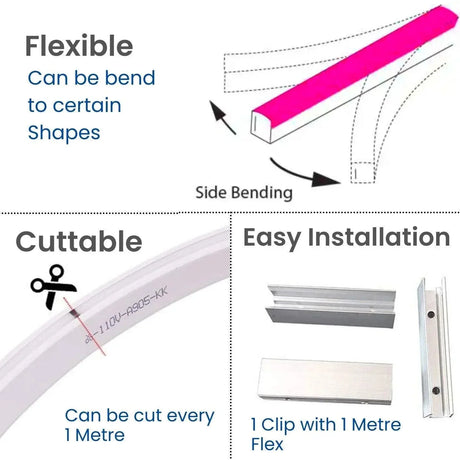

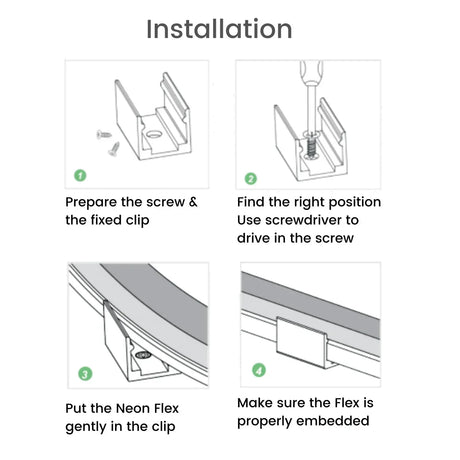

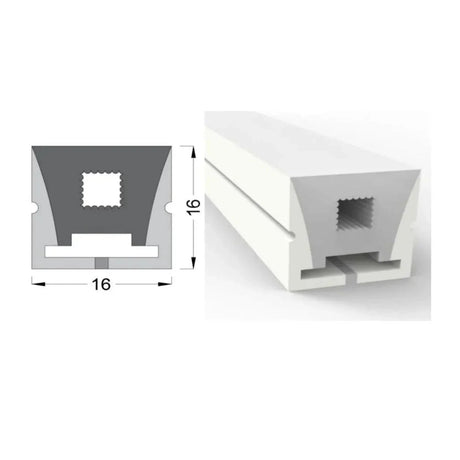

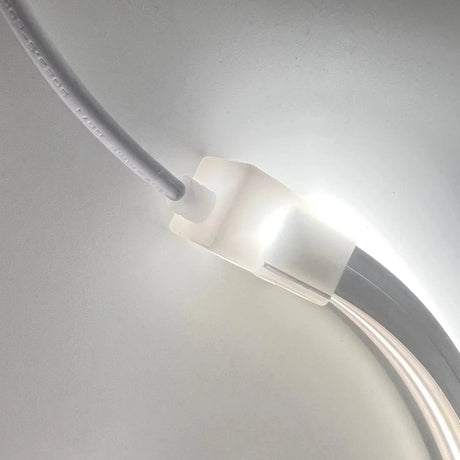

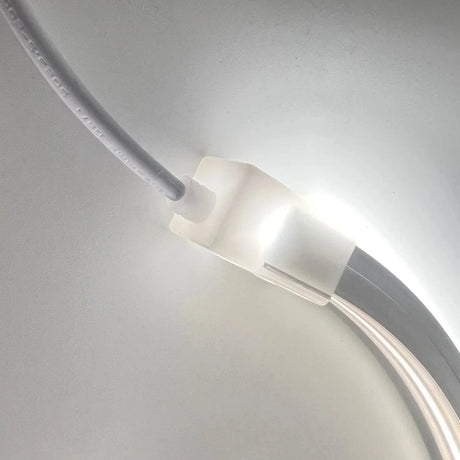

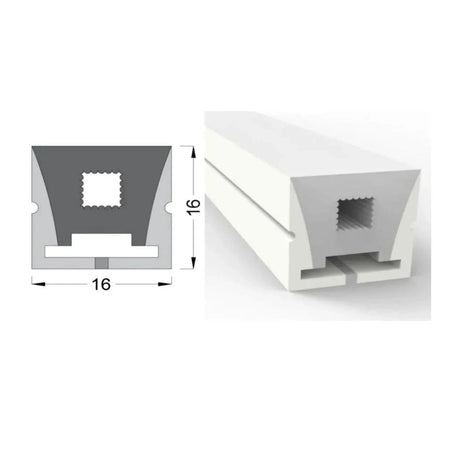

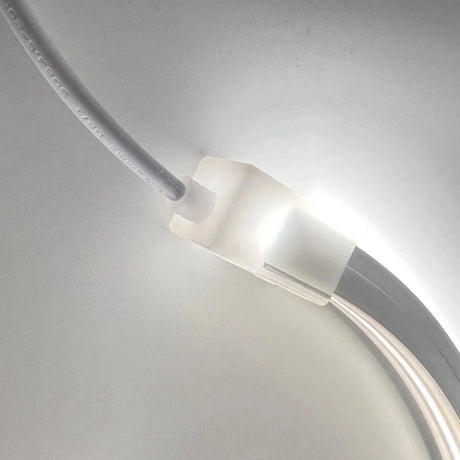

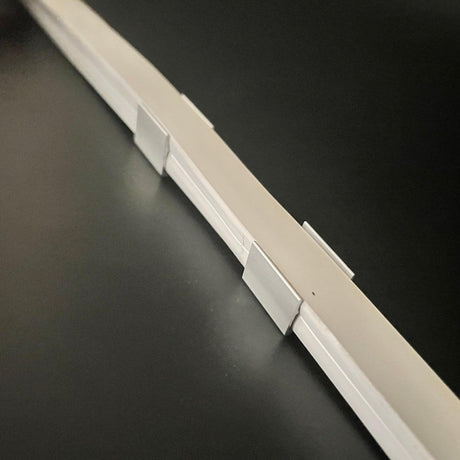

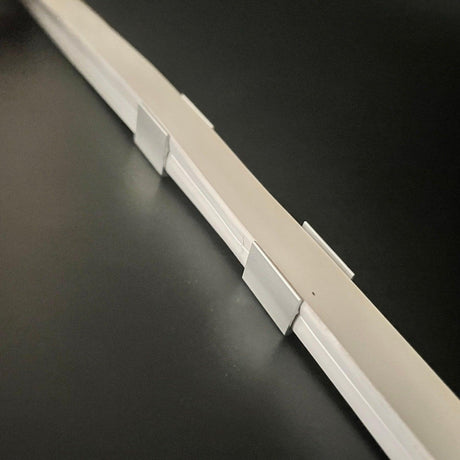

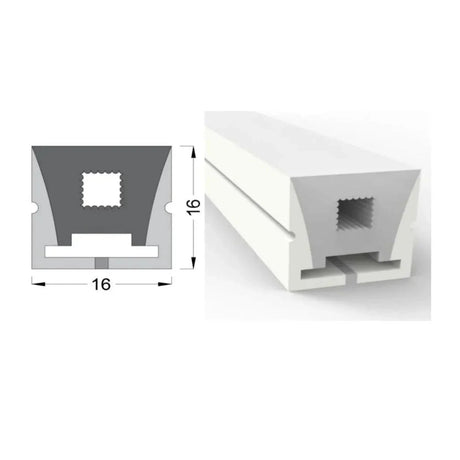

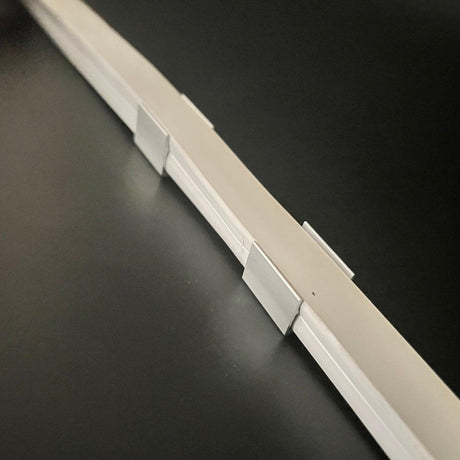

Best mounting clips for 8x16mm 230V neon flex

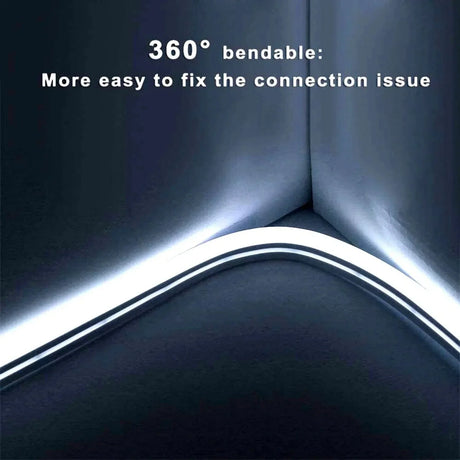

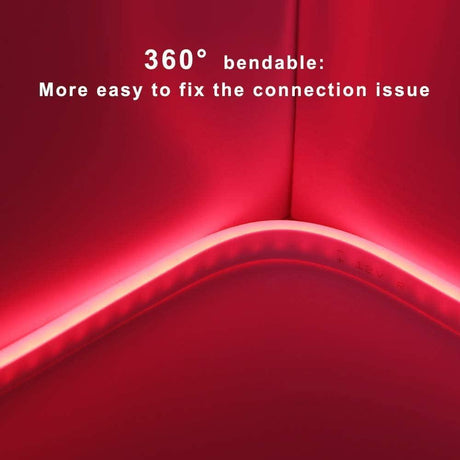

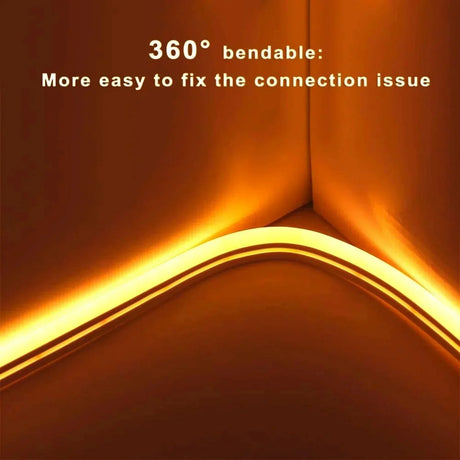

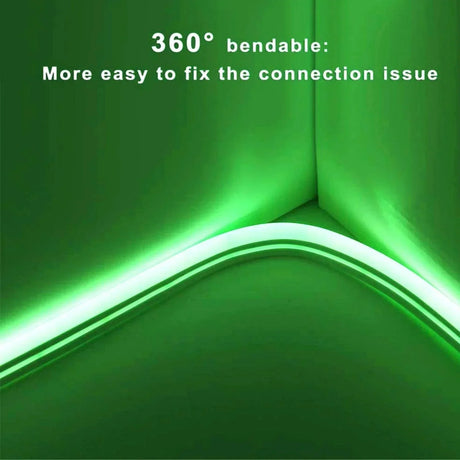

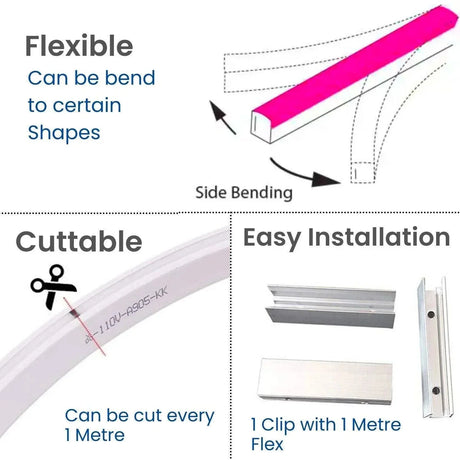

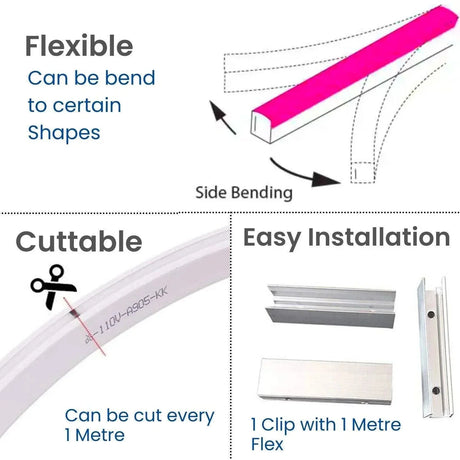

Use stainless steel or UV-stabilised polymer clips sized for 8×16mm profiles with rounded edges to avoid pinching the jacket; choose clips that allow thermal expansion and secure with appropriate fixings for the substrate.

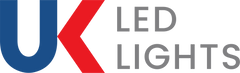

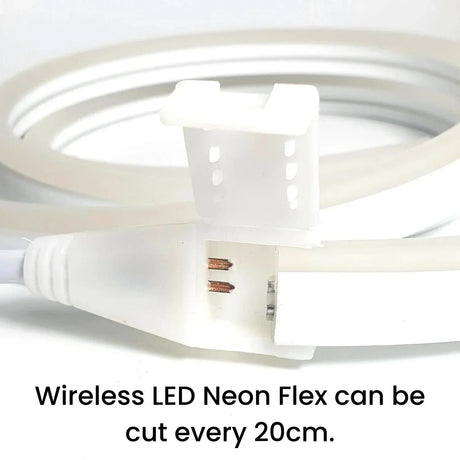

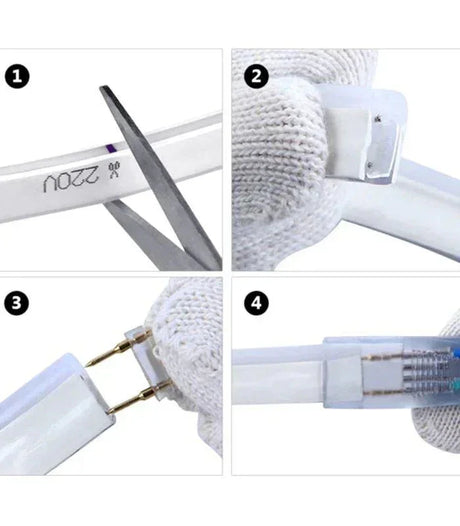

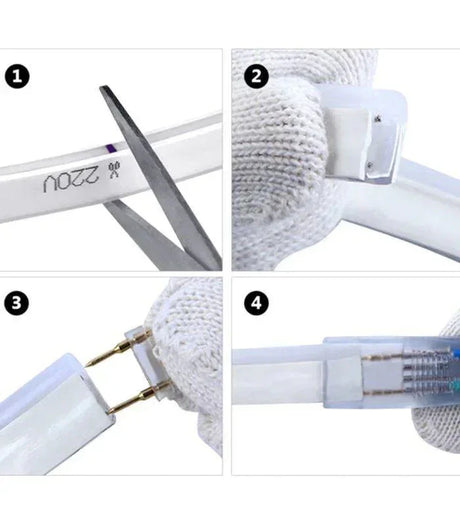

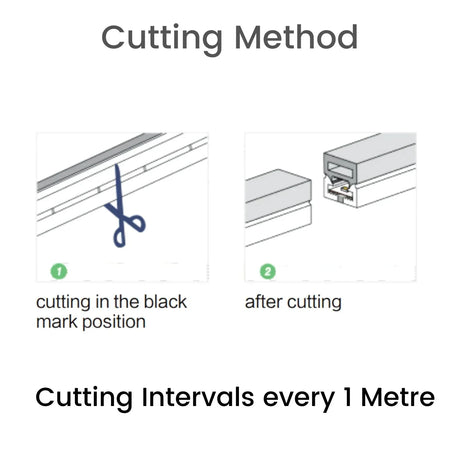

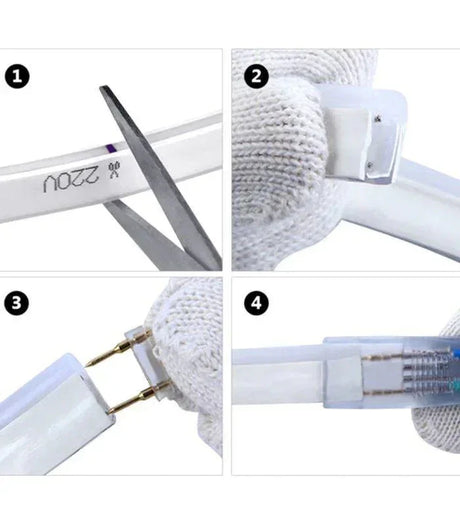

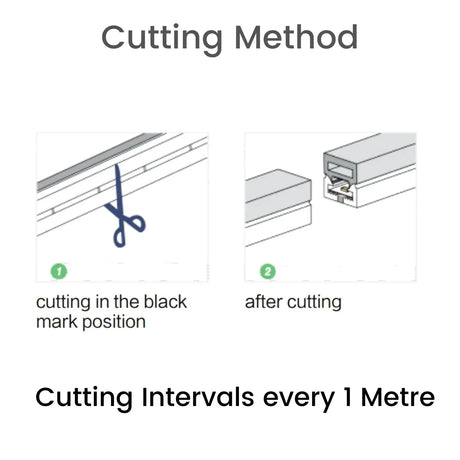

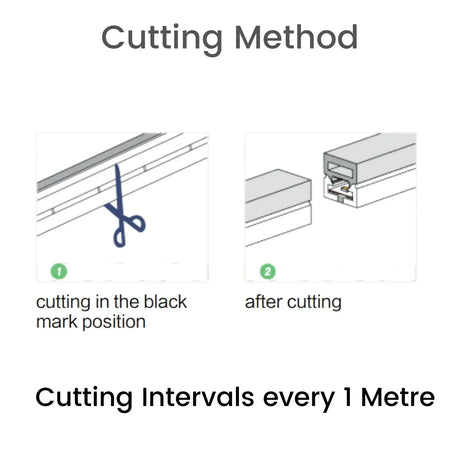

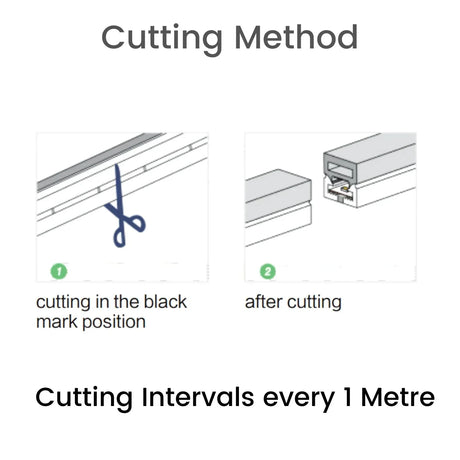

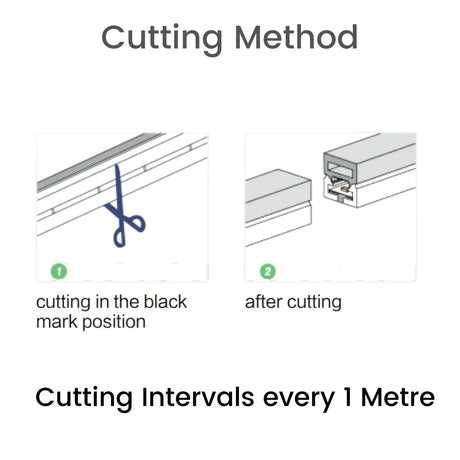

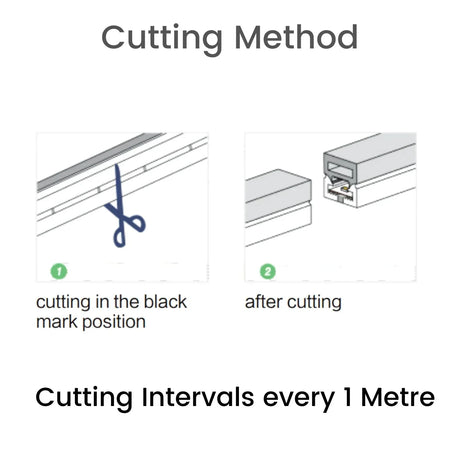

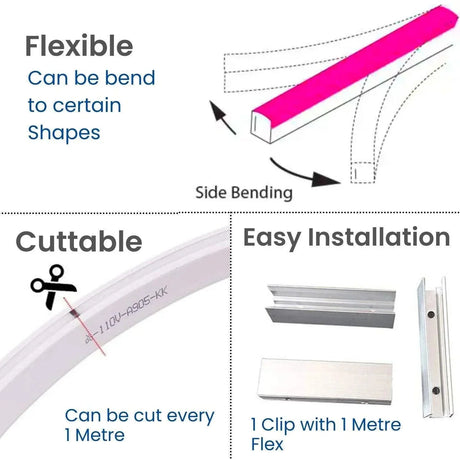

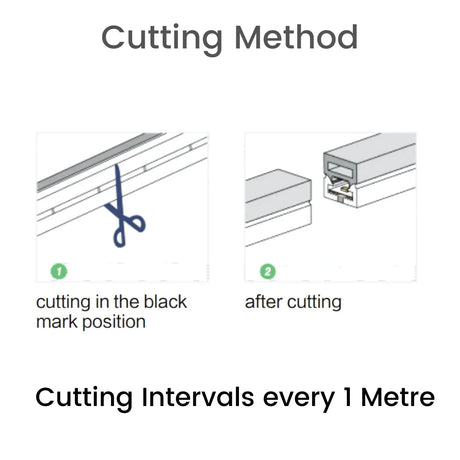

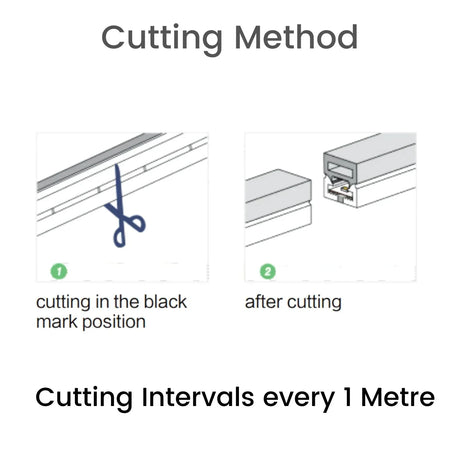

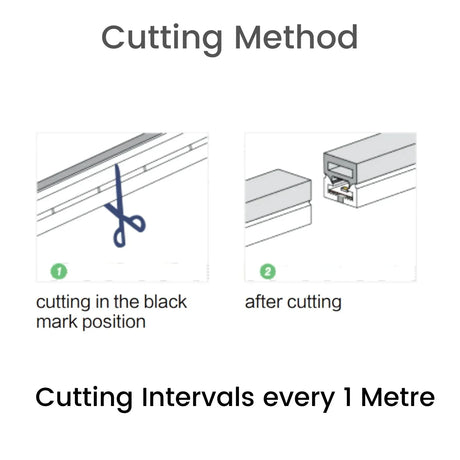

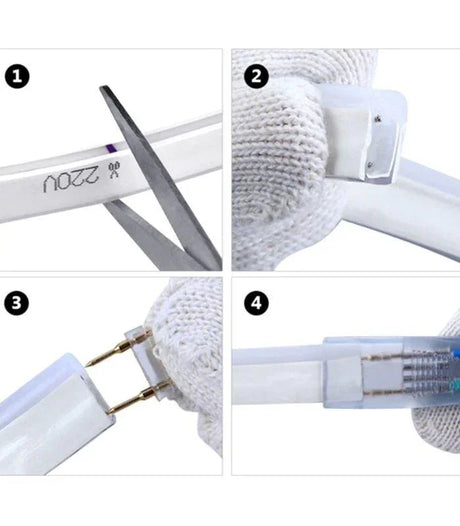

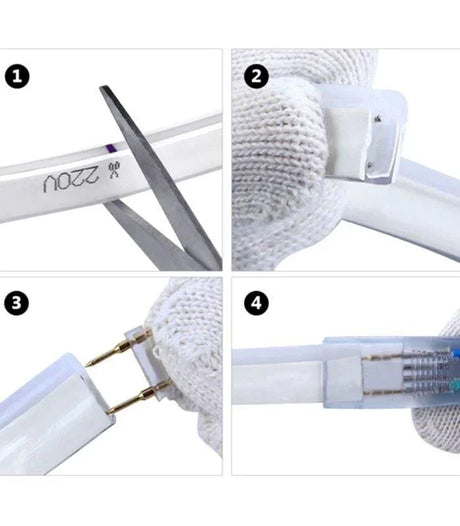

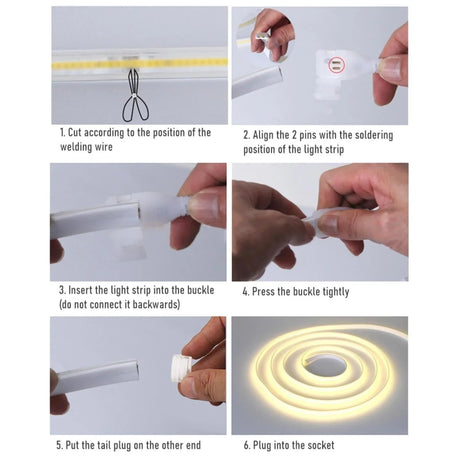

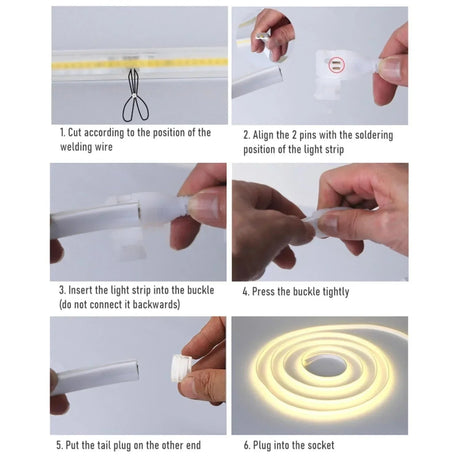

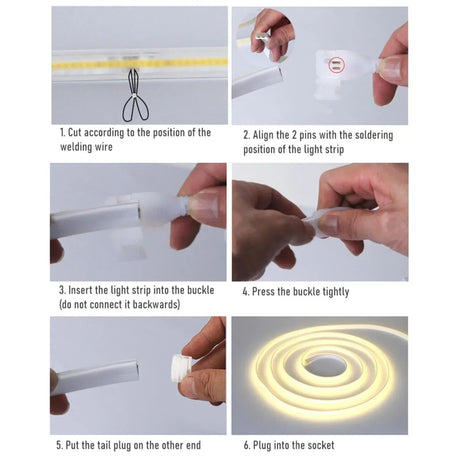

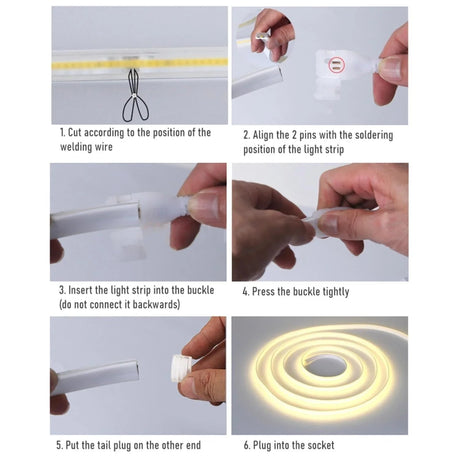

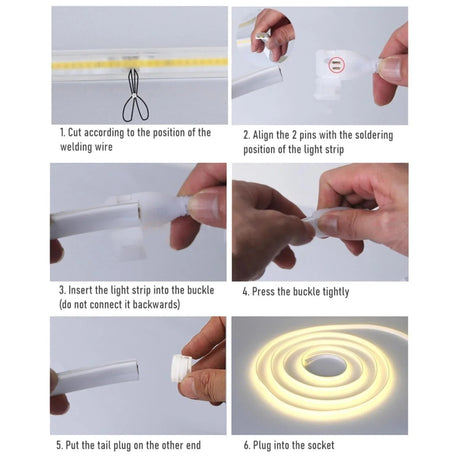

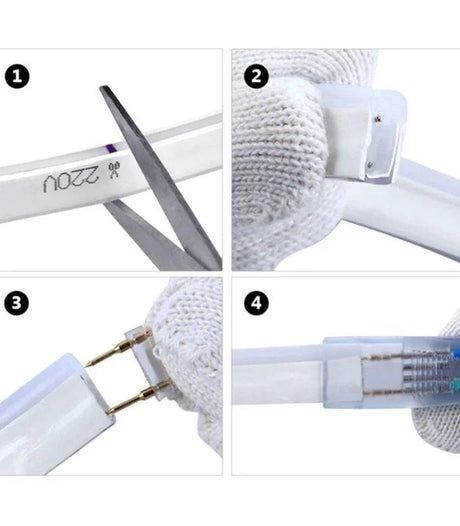

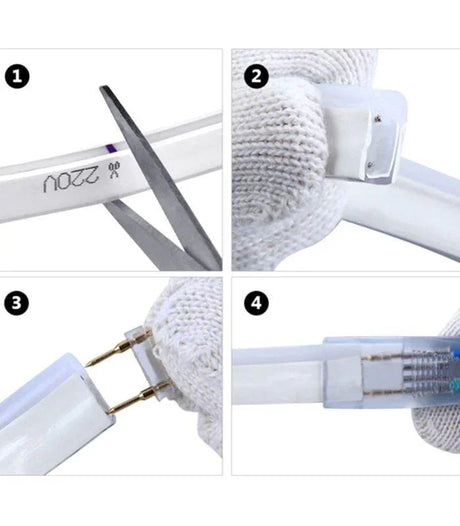

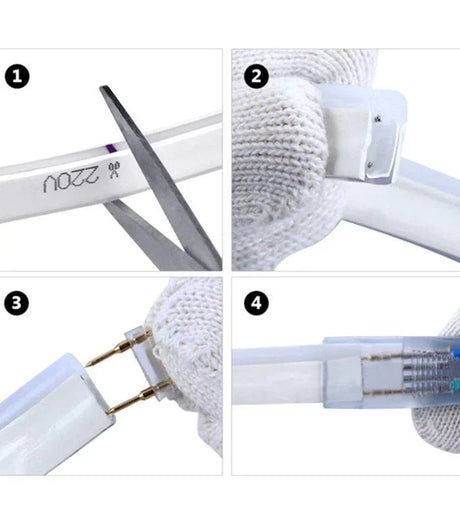

How to cut 230V neon flex safely and where cut marks are

Only cut at manufacturer-marked cut points using insulated tools, isolate mains power first, and avoid cutting through internal conductors or sealed sections if in doubt, have cuts factory-terminated.

Recommended fuse and breaker size for 230V neon flex runs

Size protective devices based on the total circuit current (total watts ÷ 230V) with an appropriate RCD and a breaker or fuse rated slightly above steady load to allow inrush (consult product inrush specs); typical circuits use 6–16 A depending on run length and load.

What is 230V Single Colour Flex and how does it differ from 12V/24V in safety, performance, and applications?

230V Single Colour Flex runs directly from mains for very long, continuous lengths with fewer power feeds but requires mains-safe installation and stricter protection, whereas 12V/24V options are lower-risk, easier for DIY and short runs but need more frequent power injection.

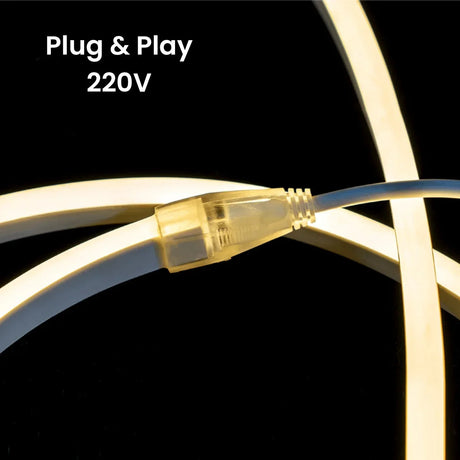

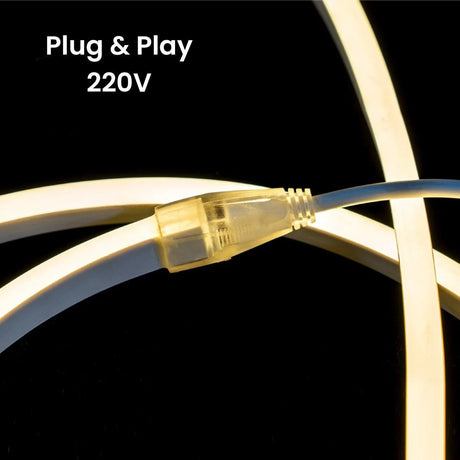

Is a separate driver needed for 230V Single Colour Flex, or can it plug directly into a UK mains socket?

Many 230V neon flex products are designed to plug directly into mains with integrated rectification, but always confirm the product’s instructions for permanent installations you should use a fixed, suitably rated mains supply and isolation/protection per local regulations.

What safety precautions should installers follow when cutting and wiring 230V Single Colour Flex outdoors?

Isolate mains power, use qualified personnel for mains terminations, use IP-rated junctions and glands, fit RCD protection, and follow local electrical codes and manufacturer termination procedures to prevent electric shock and water ingress.

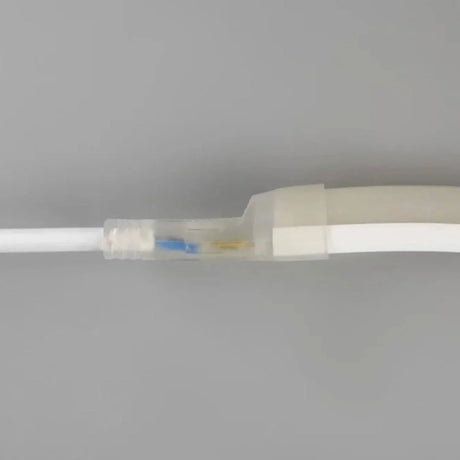

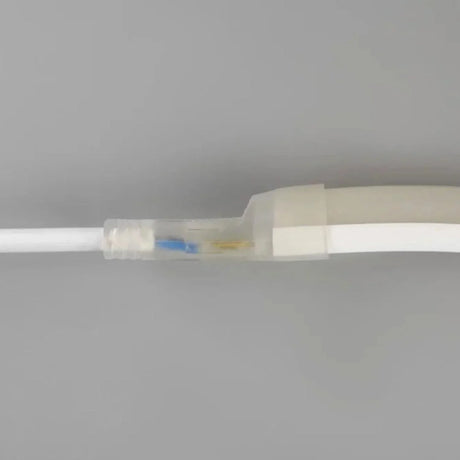

How do you correctly cut, terminate, and seal 230V Single Colour Flex while maintaining IP protection?

Cut only at marked points, fit manufacturer-approved end caps and potting compounds or silicone sealant, use adhesive-lined heatshrink or resin potting for joints, and test the assembly for water tightness before final installation.

What is the maximum recommended run length from one feed for 230V Single Colour Flex on a building outline?

Many manufacturers quote very long single-feed runs for 230V (dozens of metres), but the safe recommended length depends on wattage per metre and product specs follow the manufacturer’s maximum continuous run guidance and plan feed points accordingly.

How should junctions, connectors, and mains plugs be protected (RCDs, IP-rated boxes) in UK exterior installations?

Use IP67/IP68-rated junction boxes and cable glands outdoors, ensure all circuits are RCD-protected, mount mains supplies and controllers in weatherproof enclosures, and provide strain relief and proper earthing where required.

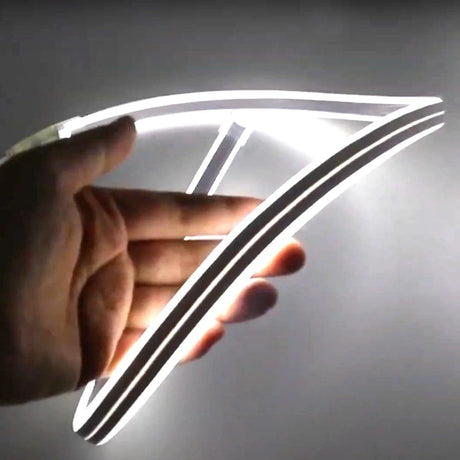

Why is 230V Single Colour Flex popular for long rooflines, retail parks, and warehouse outlines compared with 24V options?

Because it supports long continuous lengths from fewer power points, reducing trunking and labour for large perimeters and making it more economical for large-scale linear runs.

Which single colours (3000K warm white, 4000K natural white, blue) work best for commercial façades and safety demarcation?

Warm white (3000K) suits hospitality and inviting façades, 4000K is neutral for commercial façades and signage, and highly saturated colours like blue or amber are effective for safety demarcation and attention-getting outlines.

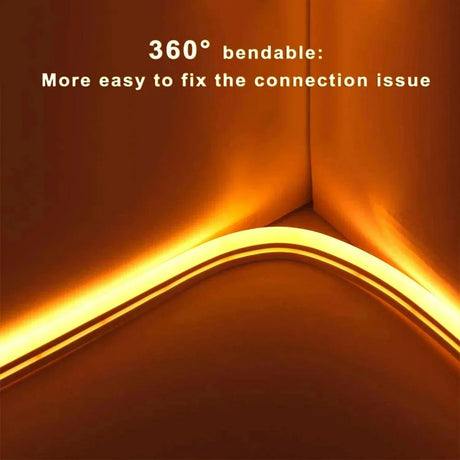

How can 230V Single Colour Flex be used for seasonal or permanent perimeter lighting on large UK properties?

Install it in continuous runs with weatherproof feeds and junctions, mount on discreet channels or clips for easy seasonal removal, or permanently fix with sealed terminations for year-round perimeter illumination.

How does the lifespan and energy use of 230V Single Colour Flex compare with low-voltage neon flex and traditional rope light?

230V LED neon flex typically matches low-voltage LED flex for energy efficiency and lifespan (often tens of thousands of hours) and is far more efficient and longer-lasting than old incandescent rope lights.

Why might a 230V single-colour run flicker, dim at the end, or fail after being cut, and how can these issues be prevented or fixed?

Common causes are poor terminations, voltage drop, incorrect cut/termination points, or water ingress; prevent by following cut marks, using correct seals, ensuring adequate feed points, and testing continuity and insulation after work.

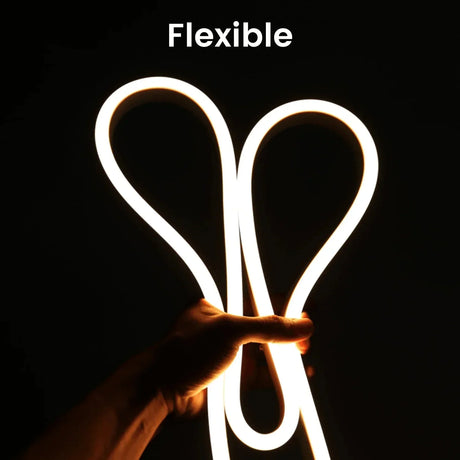

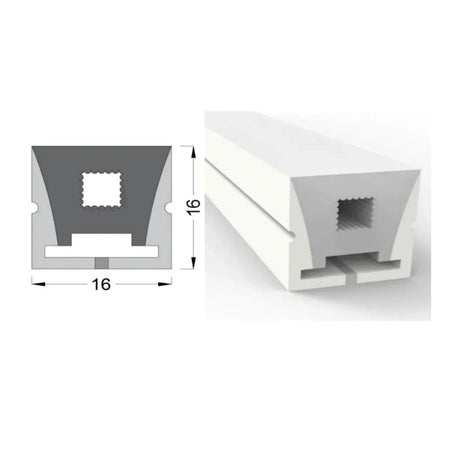

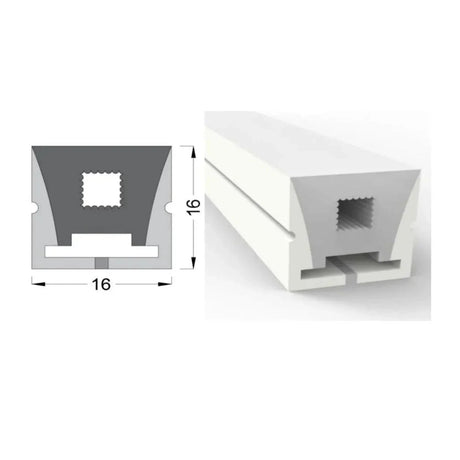

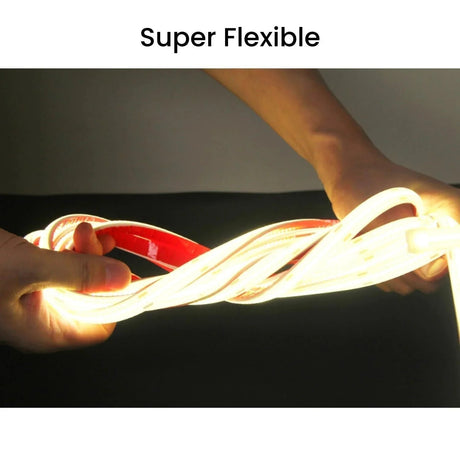

How do ambient temperature and installation method (clips vs profiles) affect thermal management and longevity at 230V?

Ambient heat and restricted airflow (clips only) can raise operating temperature and shorten life, so using aluminium profiles for heat dissipation on long or high-power runs improves thermal management and longevity.

What should buyers check when choosing 230V Single Colour Flex (IP rating, cut length, lumen/m, warranty, cable type)?

Verify the IP rating, maximum cuttable lengths and specified cut points, lumen output per metre, warranty terms, recommended cable/gland types, and any marine or UV resistance claims for the intended environment.

When is it better to choose 24V Single Colour Neon Flex instead of 230V for smaller or more detailed projects?

Choose 24V for small, intricate, or mobile projects where low-voltage safety, tighter bend radii, and easier DIY installation are priorities, or where precise local control and trimming are required.